High Temperature Steam Rotary Union For Ironing Machine

Original price was: $20.00.$15.00Current price is: $15.00.

- Size: All kinds of models and sizes

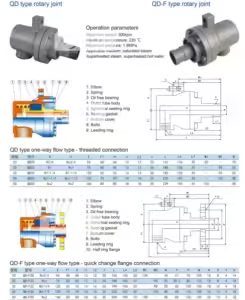

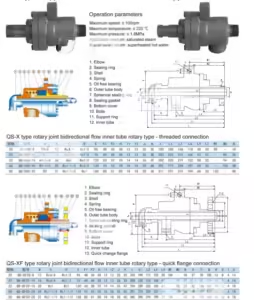

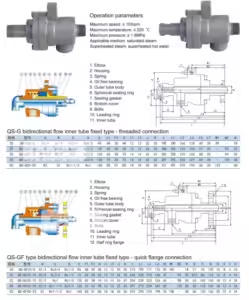

- Max.Speed: ≤300RPM

- Max. Pressure: ≤1.8MPA

- Max. Temperature: ≤220℃

- Applicable medium: Saturated steam, hot oil, superheated water, superheated st

Description

Product Overview: High Temperature Steam Rotary Union For Ironing Machine

The Steam Rotary Union, a vital component engineered for seamless and efficient steam transfer in various industrial applications. This innovative device is designed to connect stationary steam sources with rotating machinery, ensuring a leak-free operation that maintains high performance under demanding conditions.

Key Features

High-Performance Design: Capable of handling high pressures and temperatures, our steam rotary unions are constructed from durable materials that ensure longevity and reliability.

Versatile Applications: Ideal for use in power generation, chemical processing, food and beverage manufacturing, textile production, and HVAC systems.

Efficient Steam Transfer: Facilitates smooth steam flow while accommodating rotational movement, preventing leaks and optimizing energy usage.

Applications

Power Generation: Essential for turbines and generators, our steam rotary unions ensure efficient steam distribution, crucial for maintaining turbine efficiency in both thermal and nuclear power plants.

Chemical Processing: Used in reactors and agitators, these unions maintain consistent temperatures and pressure levels necessary for stable chemical reactions.

Food & Beverage Industry: Integral to equipment like steamers and pasteurizers, they ensure even steam distribution for cooking and sterilization processes.

Textile Manufacturing: Employed in dyeing machines and finishing rollers to provide continuous steam supply while allowing for the rotation of machinery parts.

Pulp & Paper Industry: Facilitates steam delivery in paper dryers and pulping machines, ensuring efficient heat transfer and consistent product quality.

HVAC Systems: Utilized in steam radiators and heat exchangers to maintain consistent heating performance in commercial buildings.

Why Choose Our Steam Rotary Union?

Our steam rotary unions stand out due to their robust construction and adaptability across various industries. With a commitment to excellence in product quality and customer service, we ensure that our solutions not only meet but exceed industry standards.

FAQ

What is a steam rotary union?

A steam rotary union is a mechanical device that allows for the transfer of steam from a stationary source to a rotating component. It features seals and bearings that enable smooth rotation while preventing leaks, making it essential in various industrial applications such as power generation and manufacturing.

How do steam rotary unions improve efficiency in manufacturing?

Steam rotary unions enhance efficiency by facilitating the rapid transfer of steam to rotating machinery. This leads to faster production cycles and improved product quality due to uniform steam distribution.

What are the benefits of using mechanical seal unions in steam applications?

Mechanical seal unions offer several advantages, including extended service life due to balanced seals, reduced maintenance costs, and enhanced performance in high-pressure environments. They designed to handle the unique challenges posed by steam applications, such as high temperatures and pressures.

What role do steam rotary unions play in power generation?

They are critical for transferring steam to turbines, which convert thermal energy into energy for electricity production. Their reliability ensures continuous operation and efficiency in thermal and nuclear power plants.

How do steam rotary unions contribute to food safety in the food industry?

In the food industry, steam rotary unions are used in equipment for cooking, pasteurization, and sterilization. They ensure even distribution of steam, which is crucial for maintaining product quality and safety by preventing undercooking or inconsistent heating.

What are the key features of high-performance steam rotary unions?

High-performance steam rotary unions include: Durable materials ; High-pressure and temperature ratings; Precision-engineered seals for leak prevention;Options for dual-flow designs to facilitate efficient operation.

What maintenance practices recommended for steam rotary unions?

Regular maintenance practices include checking seal wear indicators, inspecting for leaks or damage, and ensuring proper lubrication of bearings. Preventive maintenance can significantly extend the lifespan of the union and enhance operational reliability.

Can steam rotary unions be customized for specific applications?

Yes, many manufacturers offer customizable solutions tailored to specific operational needs. Including variations in size, pressure ratings and material selections to suit different industrial applications.