High Pressure Tower Crane Rotary Joint for Dust Removal

Original price was: $35.00.$30.00Current price is: $30.00.

- Connection: Male

- Product name: Tower Crane rotary joint

- Maximum speed: 30RPM

- Maximum temperature: 120°C

- Maximum pressure: 35MPA

Description

Tower Crane Rotary Joint: Product Details

The Tower Crane Rotary Joint is a crucial component designed to enhance the operational efficiency and safety of tower cranes. This innovative product allows for seamless rotation and fluid transfer, making it indispensable in construction and heavy lifting applications.

Key Features

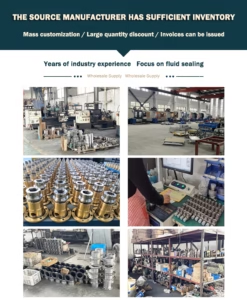

Durable Construction: Our rotary joint is made of high-quality forged technics, ensuring a robust and long-lasting performance in harsh construction site environments.

High Pressure Capability: With a maximum pressure of 35mpa, this rotary joint can handle demanding applications, providing reliable connections in high-pressure systems.

Customized Support: We offer OEM customized support, allowing for tailored solutions to meet specific user requirements, such as modifications to the product name or model number.

Wide Temperature Range: The rotary joint can operate within a maximum temperature of 120°C, making it suitable for use in various environments and applications.

Compliance with Industry Standards: Our product adheres to standard size specifications, ensuring seamless integration with existing infrastructure and meeting the needs of users who require a standard rotary joint.

Why Choose Our Rotary Joint?

Proven Reliability: Our rotary joints engineered to perform under extreme conditions, backed by rigorous testing and quality assurance processes.

Expert Support: We offer comprehensive customer support, from initial consultation to post-installation service.

Industry Compliance: Our products meet international safety and quality standards, ensuring peace of mind for operators.

FAQ

What is a rotary joint in a tower crane?

A tower crane joint is a mechanical component that allows for the rotation of parts while maintaining fluid or electrical connections. It is crucial for ensuring continuous operation during slewing or boom movements.

How do I troubleshoot a leaking rotary joint on a tower crane?

To troubleshoot a leaking rotary joint, inspect for signs of wear on seals, check alignment, and ensure proper installation. Regular maintenance and replacing worn parts can prevent leaks.

What causes rotary joint failure in tower cranes?

Common causes include improper installation, lack of lubrication, and environmental factors like contamination. Regular maintenance and following manufacturer guidelines can help prevent failures.

How often should I maintain the rotary joints on my tower crane?

Maintenance should be performed according to the manufacturer’s schedule, typically after a specified number of operating hours or at regular intervals (e.g., monthly).

What are the best practices for installing rotary joints on tower cranes?

Best practices include ensuring proper alignment, following manufacturer instructions for tightening, and using qualified personnel for installation.

Can I replace a rotary joint myself, or do I need professional help?

While some maintenance tasks can performed by in-house personnel, replacing a rotary joint often requires professional assistance to ensure proper installation and safety.

How do I prevent bolt loosening on rotary joints in tower cranes?

Regularly check and tighten bolts according to the manufacturer’s torque specifications. Use anti-loosening measures like locknuts or thread lockers to prevent loosening over time.

What are the common issues with rotary joints in tower cranes during operation?

Common issues include fluid leaks, mechanical wear, and contamination. Regular inspections can help identify these problems early.