The Ultimate Guide to Rotary Joints for Pipe Bending Machines: Design, Application, and Innovation

In modern manufacturing, efficiency and reliability are critical, and Rotary Joints for Pipe Bending Machines play a vital role in ensuring seamless media transfer, stable rotation, and reduced downtime. Whether in automotive, aerospace, construction, or metalworking industries, rotary joints are essential components that directly impact production quality and efficiency.

Also known as a rotary union or rotating union, this sophisticated device is the key to transferring fluid media between stationary and rotating parts, ensuring seamless operation. Bending machines are critical in industries where precision metal forming and tube processing are required. To achieve smooth operation, high accuracy, and long equipment lifespan, rotary joints play an essential role. These components ensure the reliable transfer of hydraulic oil, cooling water, or compressed air between stationary and rotating machine parts. This comprehensive guide will explore the intricate world of rotary joints for pipe-bending machines. We will delve into their core design principles, navigate complex technical challenges, analyze diverse real-world applications, and look toward the future of this essential industrial component.

Whether you are an engineer designing a new system, a maintenance manager aiming to maximize uptime, or a buyer seeking the best solution, this article will provide the in-depth knowledge you need.

Core Design Principles and Anatomy of a Rotary Joint

Rotary Joints fo Pipe Bending Machines are an engineering marvel designed to create a continuous, leak-proof seal while one part rotates and the other remains static. It facilitates the transfer of various media, such as hydraulic oil, coolant, compressed air, or even electrical signals. Its design is a sophisticated blend of fluid dynamics, mechanical sealing theory, and advanced material science.

Basic Structural Components

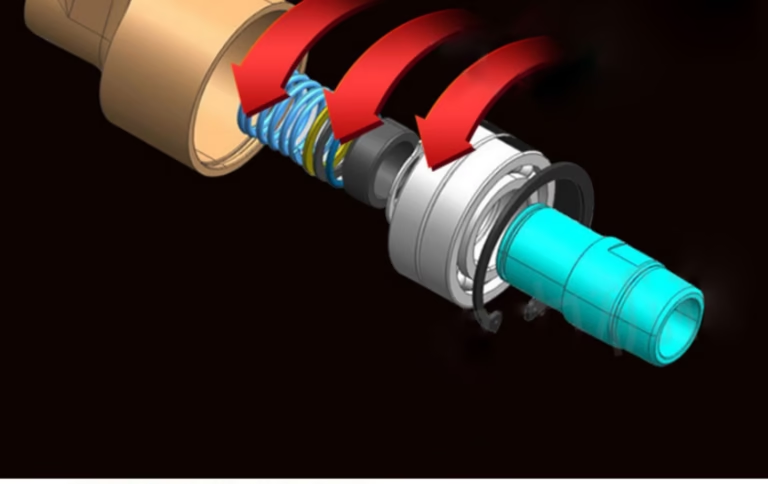

To understand how a rotary joint functions, it’s essential to know its primary components:

- Housing: The stationary part of the joint. It is typically mounted to the machine frame via flanges or threads and connects to the fixed supply lines.

- Rotor (or Shaft): The rotating component that moves in sync with the machine’s rotating member (e.g., the bending die’s hydraulic actuator). It features internal passages for fluid flow.

- Bearing Assembly: High-precision bearings (such as ball or roller bearings) are crucial for supporting the rotor, ensuring smooth, low-friction rotation, and maintaining perfect alignment with the housing.

- Sealing Assembly: This is the most critical part of the rotary joint. It’s a system of seals, often including a primary mechanical seal and secondary O-rings, designed to prevent media leakage under pressure and during rotation.

- Axial Positioning System: Typically, a spring or hydraulic system, this mechanism applies a precise amount of force to keep the seal faces in optimal contact, compensating for wear and pressure fluctuations.

In-Depth Working Principle

When a pipe-bending operation begins, the rotary joint’s rotor spins with the machine’s main spindle. The magic happens at the interface between the rotor and the stationary housing. Let’s use a hydraulic pipe bender as an example:

- High-pressure hydraulic oil is fed into the stationary housing.

- The oil flows through the housing and into the internal passages of the spinning rotor.

- The rotor delivers this pressurized oil to the rotating hydraulic cylinder of the bending die, which in turn applies the force needed to bend the pipe.

Throughout this entire process, the mechanical seal is the star player. The seal faces—one stationary and one rotating—are lapped to an incredibly fine flatness. A combination of spring force and the pressure of the fluid itself creates a dynamic balance. This balance is precise enough to form a leak-proof barrier while allowing a microscopic fluid film to lubricate the faces, preventing excessive wear and heat generation.

Key Technical Features of Modern Rotary Joints

- Self-Lubricating Systems: Many advanced rotary unions utilize composite seal materials, like graphite-impregnated silicon carbide, which offer self-lubricating properties. This drastically reduces friction and extends service life.

- Advanced Thermal Management: High-speed rotation generates significant heat. To combat this, high-performance joints incorporate features like cooling fins on the housing or dedicated cooling channels for circulating a cooling medium.

- Multi-Passage Integration: Modern manufacturing demands efficiency. Multi-passage rotary joints are a game-changer, capable of transferring multiple types of media simultaneously. For instance, one joint can deliver hydraulic oil for actuation, coolant for temperature control, and even pass through electrical signals for sensors and controls.

- Smart Monitoring Capabilities: The era of Industry 4.0 has given rise to “smart” rotary joints. These units are integrated with sensors to monitor wear, temperature, and vibration in real-time, enabling predictive maintenance and preventing costly unplanned downtime.

Overcoming Technical Challenges with Innovative Solutions

The design and manufacture of a reliable high-pressure rotary joint are fraught with technical hurdles. The main challenges lie in sealing technology, material selection, and precision engineering.

Breakthroughs in Sealing Technology

Dynamic sealing is the absolute core of rotary joint technology. While traditional packing seals have been largely superseded, the innovation hasn’t stopped.

- Mechanical Seals: The industry standard, these consist of two ultra-flat rings (one rotating, one stationary) pressed together. Material combination is key (e.g., carbon-graphite vs. silicon carbide).

- Hydrodynamic Sealing: The latest generation of sealing technology involves micro-machining microscopic patterns or textures onto the seal faces. These grooves, often created with lasers and only 5-8 micrometers deep, use the principles of fluid dynamics. As the joint rotates, they generate a hydrodynamic lifting force, creating a stable, non-contacting fluid film. This “non-contact” seal dramatically reduces friction and wear, extending the joint’s life by 3 to 5 times compared to traditional mechanical seals.

The Critical Role of Material Science

The performance of a rotary joint is defined by the materials it’s made from. The choice depends entirely on the application’s specific demands: pressure, speed, temperature, and media type.

- Silicon Carbide (SiC) Seal Rings: For applications with abrasive media (e.g., fluid with solid particulates) or high speeds, SiC is the material of choice due to its extreme hardness, excellent thermal conductivity, and chemical resistance.

- Polyetheretherketone (PEEK) Components: This advanced polymer is sometimes used for rotors or cages due to its high strength, self-lubricating properties, and excellent chemical resistance, all at a lower weight than metal.

- Advanced Surface Treatments: Techniques like tungsten carbide coating or hard-chrome plating are applied to metal components to significantly increase their surface hardness and wear resistance.

Innovations in Precision Control

Even with the best seals and materials, a rotary joint will fail without exceptional precision.

- High-Precision Bearing Preload: The axial movement of the rotor must be minimized, often controlled to within 0.02mm. This is achieved through precise preloading of the bearings, which prevents wobble and ensures the seal faces remain perfectly aligned.

Hydraulic Balancing: This is a crucial design feature for high-pressure rotary joints. It involves designing the seal in such a way that the fluid pressure itself helps to counteract the closing force on the seal faces. This prevents the sealing pressure from becoming excessive as the media pressure fluctuates, which would otherwise cause rapid wear. Some advanced “Pressure Self-Adapting Seal Systems” can automatically adjust this balance for superior performance across a wide range of operating conditions.

Application Scenarios of Rotary Joints for Pipe Bending Machines in Real-World Industries. Rotary joints have broad applications across multiple industries. Below, we will discuss typical cases and technical requirements based on specific scenarios.

Petrochemical / Pipeline Processing

In petrochemical, natural gas pipeline, and LNG projects, thick-walled or high-strength metal pipes must be precisely formed. Pipe bender rotary joints must:

Withstand high-pressure (e.g., several hundred bar) hydraulic oil or high-temperature cooling media;

Maintain sealing stability in low-temperature environments (e.g., liquid nitrogen cooling, cryogenic steel pipes);

Be resistant to corrosion, sulfidation, and hydrogen environments.

For example, one LNG project employed a dual-channel rotary joint that simultaneously transmits hydraulic oil and signal/cooling channels, enabling closed-loop control of the bending angle and achieving a bending accuracy of ±0.1°.

Automotive/Rail Transit/Heat Exchange Pipes

In the forming and processing of automotive chassis pipes, fuel pipes, cooling pipes, air conditioning pipes, and other applications:

Pipe-bending machines require continuous, high-speed operation.

Rotary joints with integrated angle sensors can be linked to robotic systems and PLC control systems.

High requirements for cleanliness, oil-free operation, and surface roughness (e.g., Ra ≤ 0.4 μm) are particularly important for high-pressure fuel pipes and refrigerant pipes.

Some new energy vehicle cooling pipe production lines utilize sanitary rotary joints, which require an oil-free interior and are suitable for clean production environments.

Building/Curtain Wall/On-site Pipe Installation

In building construction or curtain wall support pipe processing, on-site CNC portable pipe bending machines equipped with rotary joints enable mobility and flexible deployment.

For example, in high-rise curtain wall projects, designers can select high-pressure, pressure-resistant rotary joints (e.g., 300–400 bar) to ensure stable bending of large-diameter or thick-walled pipes on-site, thereby maintaining pipe bending accuracy and enhancing on-site adaptability.

Food/Pharmaceutical/Energy-Saving and Environmentally Friendly Equipment

In food/beverage/pharmaceutical/clean systems, if the tube benders are used for stainless steel pipe processing:

Manufacturers must make rotary joints from 316L or higher-grade stainless steel.

Seals and lubricants must comply with FDA/3A/CE certification.

The structural design should minimize dead angles, be easy to clean, and be contamination-free.

Moreover, in heat exchangers, heat exchange piping, and chemical equipment, rotating coils, heat exchanger end covers, and rotating drums also use rotary joints.

Special/High-End Applications

Aerospace/Aerospace: Lightweight, high-temperature, and corrosion-resistant materials, and extremely high precision levels.

Nuclear power/radiation environments: Requires radiation-resistant materials and extremely high reliability.

High-temperature/high-speed/high-pressure environments: Stable operation at speeds above 3000 r/min and temperatures between -200°C and +450°C.

How to Select the Right Rotary Joints for Pipe Bending Machines

Clarify the operating parameters. ers

- Media characteristics: Is it hydraulic oil, water, coolant, steam, air, chemically corrosive media, or fluids containing solid particles?

- Pressure range and differential pressure (maximum operating pressure, system differential pressure, pulsating pressure, etc.)

- Flow rate/diameter/number of channels

- Speed/acceleration/deceleration curve

- Temperature range/thermal expansion

- Environmental conditions (vibration, shock, temperature, dust, corrosive gases, etc.)

- Service life/maintenance cycle requirements

- Installation space/structural dimensions/interface standards

- Regulatory/certification/safety requirements (e.g., explosion-proof, sanitary, CE/ISO/ATEX, etc.)

These parameters determine the seal type, material, bearing structure, lubrication method, heat dissipation design, etc.

Seal structure selection strategy

- For medium-to-low speeds, normal temperatures, and moderate pressures: A traditional mechanical seal + O-ring combination may be sufficient.

- For high speed, high pressure, high temperature, or extreme operating conditions: Experts recommend advanced solutions such as dynamic pressure/non-contact seals and ceramic, silicon carbide, or composite seal rings.

- Media containing particles: Anti-wear materials (such as silicon carbide and ceramic) and multi-stage sealing designs are preferred.

- For long-life/maintenance cost-sensitive scenarios: Replaceable seal components, modular designs, and monitoring functions are preferred.

Bearing and Structure Matching

Select rolling bearings or plain bearing structures with sufficient load capacity and lifespan.

Consider shaft rigidity and radial/axial load capacity.

Precision control: This includes rotor and housing coaxiality, runout, and vibration levels.

Preload/balancing design: Avoid premature wear caused by uneven pressure on the sealing surfaces.

Thermal Control/Heat Dissipation Design

Design appropriate heat sink fins, heat dissipation structures, or cooling channels.

For high-speed, high-pressure, or temperature-sensitive environments, consider water/oil cooling systems.

The design of lubricating oil channels and sealing oil circuits must meet fluid dynamics and heat dissipation requirements.

Intelligent Monitoring and Maintenance Support

Support/integrate sensor interfaces for temperature, vibration, pressure, seal wear, and other functions in the design.

Support communication protocols such as Industrial Ethernet, IO-Link, and Modbus.

Remote monitoring and predictive maintenance capabilities can reduce unexpected downtime.

Supplier/Cost/Reliability Trade-offs

As an industry article points out, “Rotary fluid sealing has very specific challenges that require experience and seal expertise to overcome… Selecting a supplier is a strategic decision.” When selecting a product, consider not only the lowest price but also a comprehensive approach, including product quality, seal life, technical support, spare parts availability, and after-sales service.

Maintenance and Fault Analysis of Rotary Joints for Pipe Bending Machines

Even with the best design, rotary joints may experience failures during long-term operation. A good maintenance strategy can significantly extend their lifespan.

Daily Maintenance Recommendations

- Regularly check for seal leakage: Minor dripping (e.g., small leaks < 5 drops/minute) is acceptable; any excess should be addressed promptly.

- Regularly replace grease/oil: For example, replace with a dedicated lubricant every 2000 hours or at the recommended interval.

- Avoid pressure shock/overspeed: Soft start/pressure ramp-up mechanisms should be incorporated into the design.

- Maintain axial/radial alignment: Deformation or misalignment of the equipment body may cause uneven wear or damage to the sealing surface.

- Clean the filter/screen: Prevent particles from entering the sealing surface or lubrication channels.

- Monitor temperature/vibration/noise abnormalities: If the temperature rises suddenly or the vibration/noise increases, the machine should be shut down for inspection.

Common Fault Types and Troubleshooting

| Fault Symptom | Possible Cause | Solution/Suggestion |

|---|---|---|

| Abnormal vibration/noise | Bearing damage, misalignment, loose structure | Disassemble and inspect bearings, readjust coaxiality, and tighten structure |

| Severe media leakage | Sealing surface wear, seal structure failure, seal aging | Replace seal components, evaluate seal structure design, and upgrade sealing materials |

| Excessive temperature/uncontrolled thermal expansion | Inadequate heat dissipation design, poor lubrication, excessive friction | Optimize heat dissipation design, improve lubrication or cooling systems, and inspect seal surface contact |

| Seal failure/slip marks/scratches | Solid particle intrusion, dry start, thermal expansion shock | Install filters/particle interceptors, control the startup sequence, and adjust thermal expansion design |

| Pressure fluctuations causing seal pulsation | Improper oil circuit design, lack of buffering structures | Optimize oil circuits and install pressure stabilization/buffering devices |

Good monitoring and rapid response mechanisms are key to reducing failure risks and ensuring production continuity.

Future Development Trends and Market Opportunities

Rotary joint technology is developing in the following directions, creating potential business opportunities for export-oriented manufacturers:

Intelligence/IoT Integration

Future rotary joints will increasingly integrate sensors for temperature, vibration, wear, and pressure, enabling real-time monitoring, predictive maintenance, and fault warnings through the Industrial IoT/IIoT.

High-Speed/High-Temperature/Wide-Temperature Range Adaptability

The development of new materials and sealing structures enables rotary joints to operate reliably at higher speeds (e.g., 3000–5000 rpm and above) and in a wider temperature range (-200°C to 450°C).

Lightweight/High-Function Integration

In sectors such as aviation and rail transportation, demand for lightweight, compact, and highly integrated rotary joints will increase. The trend is towards integrating multiple channels, signal/electrical/hydraulic/cooling functions into one unit.

High-Performance Composite Materials and Advanced Manufacturing Technologies

Technologies such as carbon fiber composites, ceramic/ceramic composites, nano-coatings, self-healing materials, and novel surface texturing (microstructures, laser microtexturing) will further enhance wear resistance, seal life, and performance.

Customized/Modular Design Trends

Customer demand for customized operating conditions (such as extreme temperatures, corrosive environments, multi-channels, and high-pressure resistance) is prompting manufacturers to offer more customized solutions and modular structures to improve adaptability and delivery efficiency.

International Market and Brand Differentiation

In the export market, in addition to performance and quality, companies must prioritize comprehensive competitiveness, including certification systems (CE, ISO, ATEX, FDA, etc.), technical support, after-sales service, delivery time, and cost control. High-quality engineering cases and industry application achievements will become differentiating selling points.

Conclusion

Rotary Joints for Pipe Bending Machines are indispensable components in bending machines, directly impacting efficiency, accuracy, and operational safety. By ensuring continuous and reliable media transfer, they support industries such as automotive, aerospace, construction, and furniture manufacturing. Choosing the right rotary joint enhances machine performance, reduces maintenance, and drives productivity.