Discover the Uses of Rotary Unions Across Industries

In the intricate world of industrial machinery and fluid transfer systems, the rotary union is a crucial yet often underappreciated component. When one poses the question “What is a rotary union used for?”, the answer unfolds a fascinating story of engineering innovation designed to meet the demands of modern industrial processes. Let’s dive deep into its applications, structure, and significance.

A rotary union, also known as a swivel joint or rotary joint, is a mechanical device that enables the transfer of fluids, such as water, steam, hydraulic oil, coolant, and gases, from a stationary source to a rotating piece of equipment. This seamless transfer is essential in a wide range of industries, ensuring the smooth operation of machinery and the efficiency of various processes.

What Is a Rotary Union?

At its core, a rotary union is a specialized connector that allows media to pass between a stationary and a rotating part of a system. It acts as a pivot point, facilitating the continuous flow of fluids while accommodating the rotational movement. The primary purpose of a rotary union is to maintain a leak-proof connection under high-pressure, high-temperature, or high-speed conditions, thereby preventing fluid loss and ensuring the system’s integrity.

Engineers design rotary unions with precision to handle different types of fluids and operating conditions. They come in various sizes, configurations, and materials, depending on the specific application requirements. The design of a rotary union typically includes components such as housing, a rotor, seals, bearings, and end caps. The housing, the stationary part, connects to the fluid source, while the rotor rotates along with the equipment. Seals play a critical role in preventing leakage, and bearings support the rotation of the rotor, reducing friction and wear.

How Does a Rotary Union Work?

The working principle of a rotary union is based on the concept of separating the stationary and rotating parts of a fluid transfer system while maintaining a continuous flow of fluid. When installing the rotary union, operators connect the stationary housing to the fluid source, such as a pipe or a pump, through the inlet port. The fluid enters the housing and flows into the internal channels of the rotor.

As the equipment connected to the rotor begins to rotate, the rotor also rotates within the housing. The seals between the rotor and the housing prevent the fluid from leaking out, while the bearings allow the rotor to rotate smoothly with minimal friction. The fluid then travels through the internal channels of the rotor and exits through the outlet port, which connects to the rotating equipment.

In applications involving high-pressure or high-temperature fluids, the design of the rotary union becomes even more critical. The seals and other components must be able to withstand the harsh conditions to prevent leakage and ensure the safety and efficiency of the system. For example, in steam applications, engineers need to design the rotary union to handle the high temperature and pressure of the steam, as well as the potential for thermal expansion and contraction.

Types of Rotary Unions

Water Rotary Unions

Designers engineer these specifically for handling water-based fluids, such as cooling water in industrial processes. Water rotary unions are often used in applications where high-flow rates and relatively low pressures are involved. Manufacturers typically make them from materials that are resistant to corrosion, such as stainless steel or brass, to prevent rust and other forms of degradation caused by water.

Steam Rotary Unions

Engineers design steam rotary unions to handle the high temperature and pressure of steam. They are commonly used in applications such as steam-heated rollers in paper mills, textile factories, and food processing plants. Steam rotary unions need seals and materials that can withstand the high temperatures and the erosive effects of steam. Engineers also pay special attention to thermal expansion and contraction to ensure a tight seal under varying operating conditions.

Hydraulic Oil Rotary Unions

Hydraulic systems rely on hydraulic oil rotary unions to transfer hydraulic fluid between stationary and rotating components. Engineers design these unions to handle high-pressure hydraulic oil, which is used to power hydraulic motors, cylinders, and other hydraulic equipment. Hydraulic oil rotary unions often have high-precision seals and bearings to ensure smooth operation and prevent leakage, as even a small leak can significantly affect the performance of the hydraulic system.

Gas Rotary Unions

Engineers design gas rotary unions for the transfer of gases, such as compressed air, nitrogen, or other industrial gases. They are designed to maintain a tight seal to prevent gas leakage, which can be dangerous in some applications. Gas rotary unions may have different seal designs compared to those used for liquids, as gases can be more difficult to contain due to their low viscosity and high mobility.

Single-Passage Rotary Unions

Single-passage rotary unions are the simplest type, allowing for the transfer of a single fluid in one direction. They have a single inlet and a single outlet port and are commonly used in applications where only one fluid needs to be transferred, such as a cooling water supply to a rotating drum.

Multi-Passage Rotary Unions

As the name implies, engineers design multi-passage rotary unions to handle multiple fluids simultaneously. They have multiple inlet and outlet ports, each dedicated to a different fluid. Engineers use multi-passage rotary unions in complex industrial processes where multiple fluids, such as coolant, lubricant, and hydraulic oil, need to be transferred to a rotating component. For example, in a printing press, a multi-passage rotary union may supply ink, water for dampening, and hydraulic fluid for various moving parts.

High-Speed Rotary Unions

Engineers engineer high-speed rotary unions to operate at high rotational speeds, often in excess of 10,000 RPM. These unions require special design considerations, such as low-friction bearings and high-performance seals, to prevent excessive wear and leakage. High-speed rotary unions are commonly used in applications such as centrifuges, high-speed rotating machinery, and some types of printing presses.

High-Pressure Rotary Unions

Engineers design high-pressure rotary unions to withstand pressures well above normal operating levels. They are used in applications such as hydraulic presses, high-pressure water jetting systems, and some oil and gas exploration equipment. The construction of high-pressure rotary unions typically involves thicker walls, stronger materials, and more robust seals to ensure the integrity of the system under high-pressure conditions.

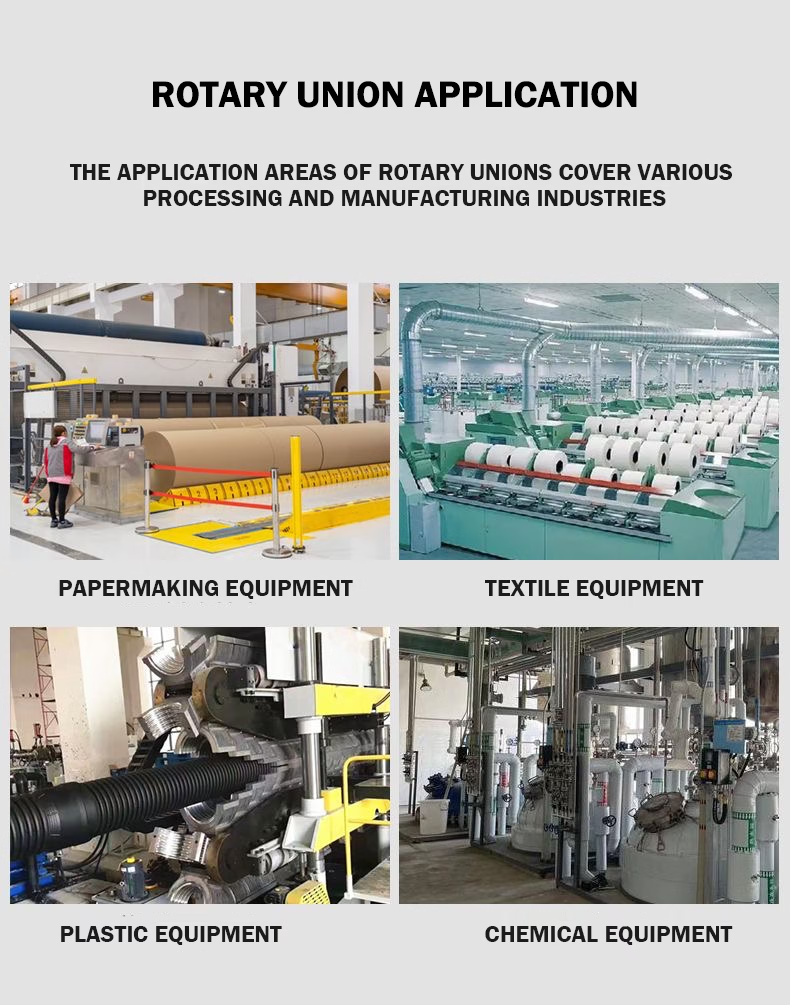

Applications of Rotary Unions

Rotary unions play a pivotal role in enabling fluid, gas, and media transfer in rotating machinery across a diverse range of industries. Their unique ability to maintain a secure, leak-proof connection while allowing continuous 360-degree rotation makes them essential in modern engineering. Below are the most common and impactful application scenarios for rotary unions:

1. Hydraulic Rotary Systems

In mobile and industrial hydraulics, rotary unions are used to transfer pressurized hydraulic oil between a fixed supply line and a rotating or swiveling part—commonly found in excavators, rotary actuators, cranes, and hydraulic manipulators.

They ensure uninterrupted hydraulic fluid flow to cylinders or motors that rotate continuously.

Especially in slewing operations (e.g., the rotation of a crane or turret), the rotary union allows multiple fluid circuits to pass through a central shaft.

Many are designed to withstand extreme pressures (up to 5000 psi) and feature multi-passage designs for complex hydraulic loops.

2. Pneumatic Automation & Robotics

In automated systems and robotics, rotary unions transfer compressed air or vacuum to end effectors or rotating tools, such as in pick-and-place robots, index tables, or automated assembly machines.

Rotary air unions eliminate the need for external tubing, which can restrict motion or tangle.

They support fast-rotating tools powered by air motors, especially in lightweight robotic wrists or rotating grippers.

Some designs combine electrical slip rings with pneumatic channels, allowing power, signal, and air to transmit through the same axis.

3. Steam and Thermal Oil Transfer in Heating Applications

In high-temperature applications, such as drying cylinders in paper machines, calendar rolls in textile mills, or plastic film processing, rotary unions handle steam, hot oil, or condensate to ensure uniform heat distribution.

These unions are built with graphite or carbon seals and stainless steel components to handle temperatures exceeding 300°C (572°F).

They allow efficient thermal energy transfer to rotating components, optimizing product drying or curing times.

Advanced models include condensate evacuation features for enhanced thermal performance and safety.

4. Coolant and Cutting Fluid Transfer in CNC Machinery

CNC machining centers rely on rotary unions to deliver coolant or lubricant through the spindle directly to the cutting tool. This is critical for high-speed milling, deep-hole drilling, and precision grinding.

They maintain a stable flow of coolant under high RPM (up to 20,000 rpm) and high-pressure conditions.

Improve tool life by reducing friction and managing heat buildup at the cutting zone.

Reduce downtime by automating fluid delivery without the need for external tubing that limits rotation.

5. Printing and Packaging Equipment

Rotary unions are indispensable in flexographic, gravure, and offset printing machines, where rotating cylinders require ink, air, cooling water, and vacuum delivered simultaneously.

Multi-passage rotary unions allow different media to pass through isolated channels in a single rotating body.

Commonly used in labeling, laminating, and film winding systems, where compact and efficient rotary distribution is essential.

Helps ensure consistent print quality by stabilizing temperature and ink delivery throughout the rotation.

6. Food and Beverage Industry

In the food processing and beverage industries, rotary unions must comply with FDA or EHEDG sanitary standards while transferring water, syrups, carbon dioxide, or cleaning fluids.

Used in rotating mixers, bottle-filling machines, and brewery tanks.

Sanitary rotary joints are made from 316L stainless steel, with crevice-free designs and PTFE seals to resist microbial growth.

Some models support Clean-In-Place (CIP) and Steam-In-Place (SIP) without disassembly.

7. Plastic, Rubber & Die-Casting Machines

Rotary unions are used to circulate hot oil or chilled water in molds and rollers in injection molding, extrusion, and die-casting operations.

Help maintain temperature consistency across mold surfaces, reducing cycle times and improving product quality.

Rotary joints with dual flow circuits enable both heating and cooling in alternating cycles.

Built to withstand abrasive environments and rapid temperature changes.

8. Wind Turbines and Renewable Energy

In wind turbine systems, rotary unions transfer hydraulic oil or coolant to the blade pitch control mechanisms, often in combination with electrical slip rings.

These systems must support long service life with minimal maintenance under offshore or remote conditions.

Capable of handling high rotational movement, extreme weather, and fluctuating power loads.

9. Aerospace and Defense Applications

Rotary unions in aerospace are used in rotating radar systems, fuel testing rigs, and aircraft landing gear test beds.

Built to military standards for vibration resistance, lightweight design, and low friction.

Custom-designed for each application, often combining electrical, optical, and fluid channels in a compact body.

10. Marine & Offshore Equipment

Engineers deploy rotary unions in offshore rigs, ROVs (Remotely Operated Vehicles), and marine cranes to transfer hydraulic fluids, seawater, or air through rotating booms or tools.

Must endure saltwater corrosion, deep-sea pressure, and harsh impact conditions.

Often equipped with ATEX or IP68 certification for explosion-proof and submersible environments.

Maintenance and Troubleshooting

Maintenance

Regular maintenance of rotary unions is essential to ensure their long-term reliability and performance. Here are some key maintenance tasks:

Inspection:

Operators should periodically inspect the rotary union for signs of leakage, wear, or damage. They should check the seals, bearings, and other components for any visible signs of deterioration. They should also look for any fluid stains or drips around the union, which may indicate a leak.

Lubrication:

Proper lubrication of the bearings is crucial for smooth operation. Operators should follow the manufacturer’s recommendations for the type and frequency of lubrication. They should use high-quality lubricants that are suitable for the operating conditions of the rotary union.

Cleaning:

Operators should keep the exterior of the rotary union clean to prevent the accumulation of dirt, debris, and contaminants. They should use appropriate cleaning agents and methods to clean the union without damaging the components. In some cases, they should also clean the internal components periodically, especially when the transferred fluid contains particulates.

Replacement of Worn-Out Components:

If operators identify any worn-out or damaged components, such as seals or bearings, they should replace them immediately. Using worn-out components can lead to leakage, increased friction, and reduced performance of the rotary union.

Troubleshooting

When problems occur with a rotary union, it is important to troubleshoot the issue quickly to minimize downtime. Here are some common problems and their possible solutions:

Leakage:

Leakage is one of the most common problems with rotary unions. If operators detect a leak, they should first check the seals. They should replace any damaged or worn-out seals. They should also check the alignment of the rotor and the housing, as misalignment can cause seals to fail. If the leak persists, they may need to inspect the internal components for damage or wear.

Excessive Noise or Vibration:

Excessive noise or vibration can indicate problems with the bearings or the alignment of the rotary union. Operators should check the bearings for wear or damage and replace them if necessary. They should properly align the rotor within the housing. They should also check for any loose components or misaligned piping that may be causing the vibration.

Reduced Performance:

A decrease in fluid flow or an increase in pressure drop may indicate that the rotary union is experiencing reduced performance due to clogged internal channels, worn components, or incorrect installation. Operators should inspect the union for any blockages and clean the internal channels if necessary. They should check the components for wear and replace them if required. They should carefully review and follow the installation process to ensure the correct installation of the rotary union.

Future Trends and Innovations

As technology continues to evolve, the field of rotary union design and manufacturing is also experiencing significant advancements. One of the key trends is the development of more efficient and reliable seals. Engineers are exploring new materials and seal designs to improve sealing performance, reduce leakage, and increase the lifespan of rotary unions. For example, the use of advanced polymers and composite materials in seals is becoming more common, as these materials offer better resistance to high temperatures, pressures, and chemical corrosion.

Another trend is the integration of smart technology into rotary unions. Engineers are equipping smart rotary unions with sensors that can monitor parameters such as temperature, pressure, vibration, and leakage. This real-time monitoring allows for predictive maintenance, enabling operators to detect potential problems before they occur and take proactive measures to prevent downtime. Engineers can analyze the data collected from these sensors to optimize the performance of the rotary union and the overall system.

In addition, there is a growing demand for more environmentally friendly rotary unions. Manufacturers are actively developing rotary unions using sustainable materials to reduce environmental impact. For example, they are exploring the use of recycled materials in the construction of rotary unions and making efforts to reduce the energy consumption and waste generated during the manufacturing process.

The miniaturization of rotary unions is also an emerging trend, especially in industries such as electronics and medical devices. As these industries require smaller and more compact components, engineers are designing rotary unions to meet these size and performance requirements. Miniature rotary unions need to have high-precision components and advanced manufacturing techniques to ensure reliable operation in small-scale applications.

Conclusion

A rotary union is a highly specialized and essential component in a wide range of industrial applications. From its basic definition and structure to its diverse types, applications, maintenance requirements, and future trends, understanding what a rotary union is and how it functions is crucial for engineers, technicians, and industry professionals. So, what is a rotary union used for? The answer spans multiple industries, from transferring hydraulic oil in cranes to conveying steam in printing rollers. These small but powerful components are the backbone of many rotating systems, enabling smooth and leak-free fluid transmission under challenging conditions. Whether you’re in manufacturing, packaging, or heavy industry, choosing the right rotary union ensures efficiency, safety, and longevity in your system.