How Do Rotary Unions Work?

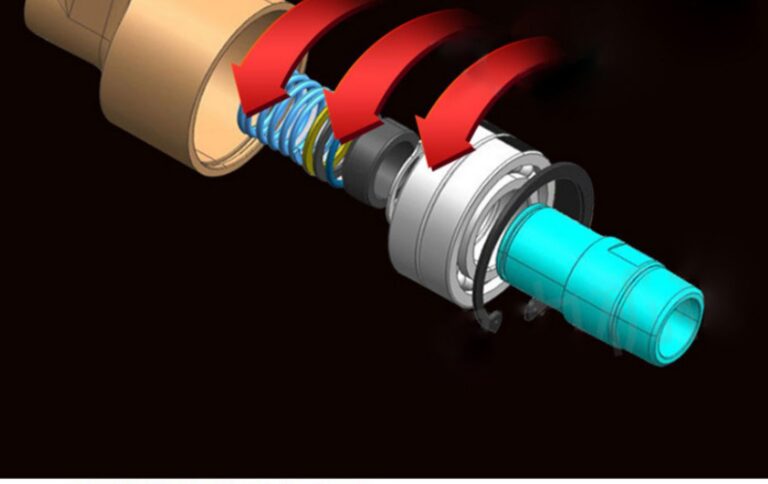

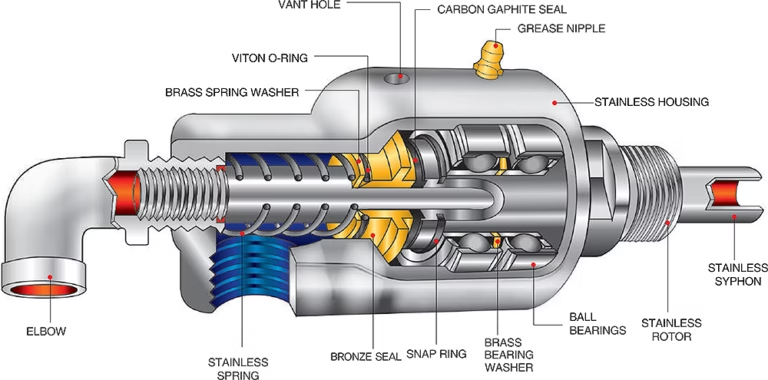

In the complex realm of industrial machinery and fluid transfer systems, rotary unions play a crucial yet often underappreciated role. These unassuming devices enable the seamless transfer of various fluids. Such as steam, water, hydraulic oil, and air. Between stationary and rotating components in a wide range of equipment. Whether in a paper mill, a…