Where would a swivel joint be found?

Swivel joints, also known as rotary unions, rotary couplings, swivel unions, rotary seals, or rotary joints, are essential components in numerous industrial applications where the transfer of fluids or gases between stationary and rotating parts is necessary. These ingenious devices enable the free rotation of equipment while maintaining a leak-free connection for media flow, solving a fundamental engineering challenge across diverse sectors. This comprehensive guide explores the various places where swivel joints can be found, their working principles, types, and selection criteria, providing valuable insights for engineers, maintenance professionals, and industry specialists.

Understanding Swivel Joints: Definition and Basic Concepts

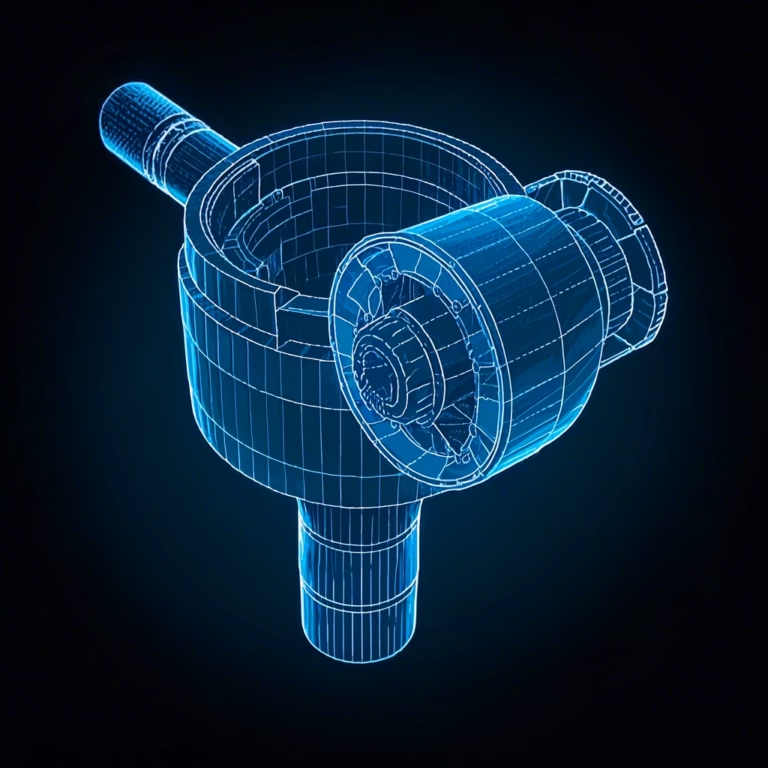

Swivel joints are mechanical devices design to provide a sealed connection between stationary and rotating components of a system while allowing the transfer of fluids, gases, or even electrical signals. The versatility of these components makes them indispensable in countless industrial applications where continuous rotation or oscillation occurs between parts. They serve as critical interfaces in systems where rigid piping or flexible hoses need to connect to rotating equipment without the risk of leakage, pressure loss, or mechanical damage.

The fundamental purpose of a swivel joint is to allow unimpeded rotational movement while maintaining the integrity of the fluid path. This dual functionality is achieved through a sophisticated design incorporating precision bearings, sealing elements, and carefully engineered flow passages. Swivel joints make it possible to use rigid metal piping for loading and unloading fluids and dry product under pressure or vacuum without the difficulty or danger of handling heavy, cumbersome hoses.

How Swivel Joints Work: Operating Principles

The operating principle of swivel joints revolves around their ability to maintain a seal while permitting rotation. This is typically accomplished through a system of bearings, seals, and precisely machined components that work together to create a reliable rotary interface.

At the heart of a swivel joint is a central shaft with holes bored through it, allowing fluid to flow from one connection to another. The swivel connects two components through this central shaft, avoiding a mass of twisted, tangled, or torn parts. As the center shaft moves independently without restricting fluid flow, both upper and lower elements can move in different directions.

Sealing is achieved through various mechanisms, including mechanical seals, o-rings, or specialized packing materials, depending on the application requirements. These seals prevent leakage between the rotating and stationary components while minimizing friction that would otherwise impede rotation or cause premature wear. Swivel joints can require anything from 3 to 10 seals to function correctly, depending on their complexity and application.

In more complex designs, multiple passages can incorporate into a single swivel joint, allowing several independent fluid streams to pass through simultaneously. These multi-passage rotary joints are particularly valuable in applications requiring the transfer of different media or where separate supply and return lines must be accommodated.

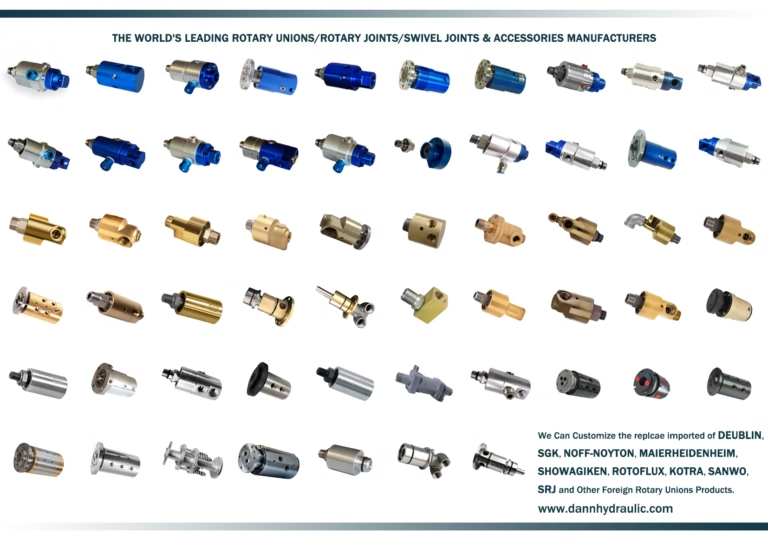

Types of Swivel Joints and Their Applications

Swivel joints come in various configurations to meet the diverse needs of different industries and applications. Understanding the types available is essential for selecting the appropriate solution for specific requirements.

1. Based on Construction Material

Stainless Steel Swivel Joints: Ideal for corrosive environments, food processing, pharmaceutical applications, and scenarios requiring high cleanliness standards.

Carbon Steel Swivel Joints: Commonly used in heavy industrial applications where high strength is needed.

Aluminum Swivel Joints: Preferred in applications where weight reduction is important.

Bronze or Brass Swivel Joints: Often selected for water applications and environments where corrosion resistance is required.

Fabricated Steel Swivel Joints: Used in specialized industrial applications requiring custom configurations.

Ductile Iron Swivel Joints: Offering good strength and impact resistance for demanding applications.

2. Based on Speed Capabilities

Low-Speed Swivel Joints: Designed for applications with intermittent or slow rotation.

Medium-Speed Swivel Joints: Capable of operating at speeds up to 800 RPM.

High-Speed Swivel Joints: Engineered for applications requiring rotational speeds of 1500-3000 RPM.

Ultra-High-Speed Swivel Joints: Specialized designs capable of operating at 5000 RPM or more.

3. Based on Connection Type

Threaded Swivel Joints: Featuring standard pipe threads for easy integration with existing piping systems.

Flanged Swivel Joints: Used in higher pressure applications or where frequent disassembly may be required.

Split Flange Swivel Joints: Offering easier installation and maintenance in certain applications.

Jacketed Swivel Joints: Providing temperature control capabilities for process applications.

Lined and Coated Swivel Joints: Featuring specialized internal surfaces for corrosion resistance or product purity.

4. Based on Passage Configuration

Single-Passage Swivel Joints: Allowing one fluid stream to pass through the rotary interface.

Dual-Passage Swivel Joints: Accommodating two independent fluid paths, typically supply and return.

Multi-Passage Swivel Joints: Providing three or more separate flow paths through a single rotary joint.

Industrial Applications: Where Swivel Joints Are Found

Swivel joints are utilized across numerous industries, solving fluid transfer challenges in rotating equipment. Let’s explore the major sectors where these versatile components can be found:

1. Oil, Gas, and Petrochemical Industry

The petroleum sector relies heavily on swivel joints for various operations:

1.1 Loading Arms

At terminals and refineries, swivel joints are crucial components in loading arms used for transferring petroleum products between storage facilities and transportation vessels (trucks, ships, rail cars). These loading arms require multiple points of rotation to provide the necessary flexibility for connecting to different vehicles.

1.2 Refinery Equipment

Throughout refineries, swivel joints enable the connection of flexible piping systems to rotating machinery, facilitating maintenance and accommodating thermal expansion while maintaining process integrity.

1.3 Drilling Operations

On drilling rigs, swivel joints are found in the rotary equipment that drives the drill string, allowing drilling fluids to be pumped down through the rotating drill pipe.

1.5 Pipeline Maintenance

Sewer rodding equipment used for pipeline cleaning and maintenance incorporates swivel joints to allow the flexible movement needed to navigate through complex piping systems.

2. Manufacturing and Machinery: Where Swivel Joints Found

Swivel joints are found in industrial settings, where they manage high-pressure fluids, corrosive chemicals, and extreme temperatures.

2.1 Hydraulic and Pneumatic Systems

High-pressure swivel joints (up to 10,000 PSI) are critical in hydraulic machinery for transferring oil, water, or air. In pneumatic systems, these joints reduce friction in air-driven tools, enhancing efficiency in manufacturing plants

2.2 Machine Tool Coolant Systems

CNC machines and other machine tools utilize swivel joints to deliver coolant to cutting tools on moving or rotating parts of the machine.

2.3 Printing Presses

The paper-making and printing industries use rotary joints to transfer inks, coolants, and lubricants to rotating cylinders and drums.

2.4 Textile Machinery

In textile production equipment, swivel joints enable the delivery of steam, air, or other process fluids to rotating drums and cylinders used in dyeing, drying, and finishing operations.

2.5 Plastics and Rubber Processing

Extruders, injection molding machines, and other polymer processing equipment incorporate swivel joints to transfer heating or cooling media to rotating barrels and molds.

2.6 Drum Filling Systems

Automated drum filling operations utilize swivel joints to connect fill lines to rotating carousel-type filling machines.

3. Agriculture and Irrigation

The agricultural sector employs swivel joints in several applications:

3.1 Center Pivot Irrigation Systems

These large-scale irrigation systems use multiple swivel joints to allow water to flow through the rotating pivot points as the system moves across a field.

3.2 Fertilizer Application Equipment

Modern precision agriculture equipment incorporates swivel joints in systems designed for the application of liquid fertilizers.

3.3 Crop Spraying Equipment

Rotary connections in spraying booms and distribution systems rely on swivel joints to maintain fluid integrity during operation and folding.

4. Mining and Material Handling

Swivel joints are essential components in mining operations and material handling systems:

4.1 Continuous Miners

These machines use swivel joints in their hydraulic systems to maintain fluid connections to moving cutting heads.

4.2 Conveyor Systems

Transfer points in complex conveyor arrangements may incorporate swivel joints to accommodate directional changes while maintaining dust suppression spray systems.

4.3 Loading Equipment

Excavators and other heavy loading machines utilize swivel joints in their hydraulic circuits to connect the upper rotating superstructure with the lower fixed undercarriage. The swivel joint plays a key role in controlling hydraulic circuits on an excavator, allowing the mechanical arm to maneuver, reposition the bucket, adjust the digging angle, and control the tracks or wheels.

5. Wastewater and Environmental

Environmental applications frequently incorporate swivel joints:

5.1 Wastewater Treatment Equipment

Rotating biological contactors, clarifiers, and other rotating equipment in wastewater treatment plants utilize swivel joints to connect process piping to moving components.

5.2 Sewer Cleaning Equipment

Sewer rodding and jetting machines incorporate swivel joints to allow flexible operation while maintaining high-pressure water connections.

5.3 Environmental Sampling Systems

Rotating sampling devices used in environmental monitoring may incorporate swivel joints to maintain fluid or vacuum connections.

6. Food and Beverage Production

The food industry has specialized applications for swivel joints:

6.1 Brewing Equipment

Brewing processes utilize swivel joints in rotating vessels and transfer systems where temperature control media or product must be moved between stationary and rotating components.

6.2 Distilling Equipment

Similar to brewing, distillation processes involve rotary equipment with heating or cooling jackets that require media transfer through swivel joints.

6.3 Filling and Packaging Lines

Rotary filling machines for bottles, cans, or other containers use swivel joints to maintain product supply to rotating filling heads.

6.4 Food Processing Equipment

Cookers, mixers, and other food processing machinery with rotating vessels often incorporate swivel joints for steam, cooling water, or product transfer.

7. Other Specialized Applications

Beyond these major categories, swivel joints found in numerous specialized applications:

7.1 Ink and Paint Industries

Various equipment used in the production and application of inks and paints utilize swivel joints for fluid transfer to rotating components.

7.2 Chemical Processing

Reactors, mixers, and other chemical processing equipment with rotating elements incorporate swivel joints for transferring reactants, products, and process utilities.

7.3 Robotics

Industrial robots may use swivel joints in end-effector tooling where fluid power or vacuum must be transferred to rotating implements.

7.4 Marine Applications

Ships and offshore platforms use swivel joints in loading systems, crane hydraulics, and various utility connections.

Advantages and Functions of Swivel Joints

Swivel joints offer numerous benefits that make them indispensable in many industrial applications:

1. Operational Benefits

1.1 Elimination of Hose Twisting

By providing a rotating connection point, swivel joints prevent the twisting, kinking, and potential damage to hoses that would otherwise occur in rotating applications.

1.2 Reduced Maintenance

Properly specified and maintained swivel joints can significantly reduce system downtime and maintenance costs by eliminating stress on connected components.

1.3 Enhanced Safety

By providing a secure connection for transferring fluids under pressure or vacuum, swivel joints reduce the risk of leaks and associated hazards.

1.4 Increased Equipment Longevity

The reduction in stress on hoses, pipes, and other connected components leads to longer service life for the entire system.

2. Functional Capabilities

2.1 Pressure Handling

Modern swivel joints can accommodate a wide range of operating pressures, from vacuum to high-pressure applications.

2.2 Temperature Compatibility

Specialized designs allow operation across extreme temperature ranges, from cryogenic to high-temperature processes.

2.3 Media Versatility

From clean water to corrosive chemicals, abrasive slurries to high-purity gases, swivel joints can be engineered to handle virtually any fluid medium.

2.4 Load Bearing

Some swivel joint designs (particularly those with two bearing tracks) can carry significant bending moment loads, supporting connected piping and equipment.

Selection Considerations for Swivel Joints

Choosing the appropriate swivel joint for a specific application requires careful consideration of several factors:

1. Application Parameters

1.1 Rotational Requirements

The speed, frequency, and arc of rotation will determine the type of bearings and seals required.

1.2 Pressure and Temperature

Operating pressure and temperature ranges must be within the capabilities of the selected swivel joint.

1.3 Media Compatibility

The materials used in the swivel joint must be compatible with the fluid or gas being transferred.

1.4 Environmental Conditions

Exposure to weather, corrosive atmospheres, or other environmental factors may necessitate special materials or protective features.

2. Design Considerations

2.1 Flow Requirements

The passage size must be sufficient to accommodate the required flow rate with acceptable pressure drop.

2.2 Connection Types

The interface to connecting piping or equipment must be appropriate for the application (threaded, flanged, etc.).

2.3 Space Constraints

Physical size limitations may dictate the selection of compact designs.

2.4 Maintenance Access

The installation should allow for periodic maintenance and eventual replacement.

3. Reliability Factors

3.1 Expected Service Life

The duty cycle and operating conditions will influence the longevity of the swivel joint.

3.2 Seal Design

Different sealing technologies offer various trade-offs between friction, leakage prevention, and service life.

3.3 Bearing Selection

The type and quality of bearings used will affect rotational smoothness and load capacity.

3.4 Material Quality

Higher-grade materials may be justified in critical applications where failure would have significant consequences.

Maintenance and Troubleshooting of Swivel Joints

Proper maintenance is essential for ensuring the reliable operation and longevity of swivel joints:

1. Preventive Maintenance

1.1 Regular Inspection

Periodic visual inspection can identify early signs of leakage, wear, or damage.

1.2 Lubrication

Many swivel joints require regular lubrication of bearings and seals according to manufacturer recommendations.

1.3 Seal Replacement

Proactive replacement of seals before failure can prevent unexpected downtime and potential damage.

1.4 Torque Checking

Verifying that mounting bolts and connections maintain proper torque can prevent leakage and damage.

2. Common Issues and Solutions

2.1 Leakage

Often caused by worn seals, misalignment, or damage to sealing surfaces. Replacement of seals or repair of damaged components is typically required.

2.2 Excessive Friction

May indicate bearing issues, inadequate lubrication, or seal problems. Proper lubrication or component replacement can resolve these issues.

2.3 Contamination

Introduction of foreign material into the swivel joint can cause accelerated wear and failure. Proper filtration and environmental protection can mitigate this risk.

2.4 Vibration

Excessive vibration may indicate bearing wear or imbalance in the rotating system. Address by examining the entire rotating assembly and replacing damaged components.

Conclusion

Swivel joints are found in an extraordinarily diverse range of industrial applications, from oil refineries to food processing plants, from agricultural irrigation systems to high-speed manufacturing equipment. Their ability to maintain fluid integrity while allowing rotational movement solves a fundamental engineering challenge, enabling the design and operation of complex systems that would otherwise be impossible.

Understanding where swivel joints are found, how they work, and how to select the appropriate type for a specific application is essential knowledge for engineers, maintenance professionals, and industry specialists. By considering the full range of factors—from operating parameters to maintenance requirements—users can ensure optimal performance and longevity from these critical components.

Swivel joints represent a perfect example of specialized industrial components that, while often overlooked, play a crucial role in the reliable operation of countless systems across virtually every industry. Whether enabling an excavator to rotate its upper structure while maintaining hydraulic connection to its tracks, allowing a printing press to deliver ink to rotating drums, or facilitating the loading of petroleum products onto tanker trucks, these versatile devices continue to prove their worth in modern industrial applications.

As industry requirements continue to evolve and technology advances, swivel joints will undoubtedly continue to adapt and improve, maintaining their crucial role in the efficient and reliable transfer of fluids in rotating systems across all industrial sectors.