High-Performance Rotary Union for Paper Manufacturing Systems

Original price was: $35.00.$30.00Current price is: $30.00.

- Connection: Male

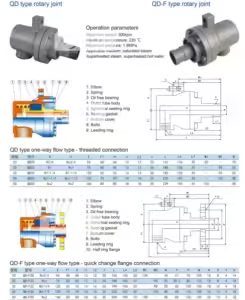

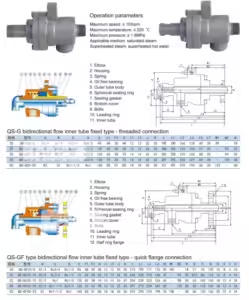

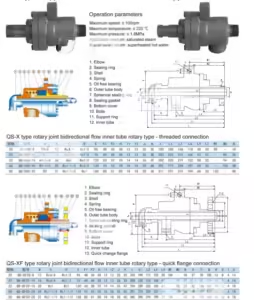

- Product name: Rotary union for paper manufacturing

- Medium: Steam

- Standard: ANSI

- Color: Customized

- Tolerable temperature: 220℃

- Maximum speed: 300RPM

- Apply pressure: 2MPA

Description

Product Overview

Our Rotary Union for Paper Manufacturing is specifically designed to meet the demanding needs of modern paper mills. With high-speed capability, exceptional sealing technology, and corrosion-resistant materials, it ensures uninterrupted fluid transfer under high temperature and pressure conditions. Whether used for steam, water, or thermal oil, this rotary union delivers long-lasting performance and minimal maintenance requirements. This advanced rotary union is essential for various applications in the paper industry, ensuring reliable performance in high-pressure and high-temperature environments.

Key Features

High-Speed Performance

Engineered for fast rotary applications in paper processing systems, ensuring consistent media flow without leakage.

Exceptional Sealing Technology

Equipped with advanced mechanical seals and carbon-graphite materials to resist wear and maintain tight sealing under thermal expansion.

Robust Construction

Built from stainless steel and hardened components to withstand corrosive fluids, high temperatures, and continuous operation in harsh environments.

Leak-Free Operation

Precision-machined components and dynamic balancing provide stable, leak-free performance at various speeds and pressures.

Extended Service Life

Reduced maintenance downtime due to bearingless designs and wear-resistant materials improves overall equipment efficiency.

The Rotary Union for Paper Manufacturing is crucial in various applications:

Drying Processes

Essential for connecting steam pipes to dryer cylinders, allowing efficient heat transfer to evaporate moisture from the paper.

Calendering Operations

Used in calender rolls to maintain optimal surface temperatures, ensuring high-quality finishes such as gloss or matte on paper products.

Flexographic Printing

Supports fluid transfer in flexographic printing machines, controlling temperature during the printing process for better ink adhesion and drying.

Why Choose Us?

With extensive experience in the paper industry, we dare to dedicate ourselves to providing innovative products that enhance production efficiency. Our rotary unions are manufactured using state-of-the-art technology, ensuring they meet the highest industry standards.

Increased Production Efficiency

Our rotary union reduces downtime and enhances overall efficiency.

Lower Maintenance Costs

The durable construction and advanced sealing technology lead to reduced wear and tear. Minimizing maintenance requirements and associated costs.

Customizable Solutions

We offer tailored rotary unions that can be customized to meet specific operational needs, including size, pressure ratings, and fluid types.

FAQ

What is a Rotary Union for Paper Manufacturing?

A Rotary Union for Paper Manufacturing is a mechanical device that connects stationary piping to rotating machinery, allowing for the efficient transfer of fluids such as steam, water, and thermal oils. This is crucial in various stages of paper production, including drying and cooling processes.

How do Rotary Unions enhance the efficiency of paper production?

Rotary Unions facilitate uninterrupted fluid flow, which minimizes downtime and enhances production rates. They operate under high pressures and temperatures, ensuring optimal performance in the demanding environments typical of paper manufacturing processes.

What materials are commonly used in Rotary Union construction?

Manufacturers typically use corrosion-resistant materials like stainless steel to make rotary unions. They construct seals from carbon graphite or fluorocarbon to ensure durability under high-pressure conditions and prevent leakage.

What are the pressure and temperature ratings typically found for paper manufacturing?

Most unions can handle pressures ranging from 0 bar up to 20 bar (290 psi) and temperatures reaching 250°C. Making them suitable for various applications across different grades of paper.

Request a Quote or Sample Today!

Request a Quote or Sample Today!

Upgrade your paper production line with our Rotary Union for Paper Manufacturing. Contact us now for pricing, custom configurations, or technical drawings.