Hydraulic Swivel Joint Explained: Function, Design, and Applications

In industrial machinery where rotational motion and fluid transfer must coexist, hydraulic swivel joint (also known as hydraulic rotary unions) serve as critical connectors. These devices enable the seamless flow of hydraulic oil, water, or other fluids between stationary and rotating components, such as in cranes, excavators, wind turbines, and manufacturing equipment. Understanding how a hydraulic swivel works is essential for engineers, maintenance professionals, and industry stakeholders seeking to optimize performance, prevent leaks, and extend equipment lifespan. This detailed guide breaks down the mechanics, components, design considerations, and real-world applications of hydraulic swivels.

Fundamental Principles of a Hydraulic Swivel Joint

A hydraulic swivel is a mechanical component designed to transfer pressurized fluids between a stationary pipe or hose and a rotating shaft, arm, or mechanism. Its core purpose is to maintain a leak-proof connection while allowing unrestricted rotation, making it indispensable in systems where motion and fluid flow are interdependent.

1. Basic Working Mechanism

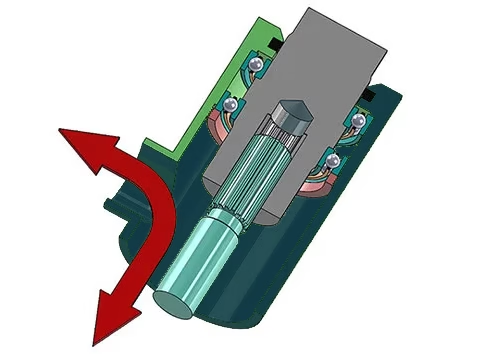

At its simplest, a hydraulic swivel operates on the principle of separating stationary and rotating elements while maintaining fluid continuity. The device consists of two main parts:

Stationary Housing: Connected to the fixed fluid source (e.g., a pump or reservoir).

Rotating Shaft or Inner Element: Attached to the moving component (e.g., a crane boom or robotic arm).

Fluids enter the swivel through the stationary housing, pass through internal channels, and exit via the rotating shaft into the moving system. The magic lies in the interface between these two parts: a carefully engineered sealing and bearing system that allows rotation without compromising pressure integrity.

2. Key Objectives of a Hydraulic Swivel Joint

Fluid Transfer Under Rotation: Enable continuous flow during 360° rotation.

Pressure Containment: Maintain seal integrity at high pressures (ranging from 100 PSI to over 10,000 PSI).

Minimize Friction: Ensure smooth rotation to reduce wear and energy loss.

Durability: Understand harsh environments, including high temperatures, vibrations, and contaminants.

Essential Components of a Hydraulic Swivel Joint

To understand how a hydraulic swivel works, it’s crucial to examine its key components, each designed to address specific mechanical and fluidic challenges:

1. Rotating Shaft (Rotor)

Function: Transmits fluid to the rotating part of the system; must withstand torque, radial/axial loads, and fluid pressure.

Materials: Typically made from high-strength alloys (e.g., 4140 steel) for durability or stainless steel (316 SS) for corrosion resistance in harsh environments.

Design Features:

Precision-machined surfaces to ensure tight seal contact.

Internal passages (bores) for fluid flow are often engineered for minimal pressure drop.

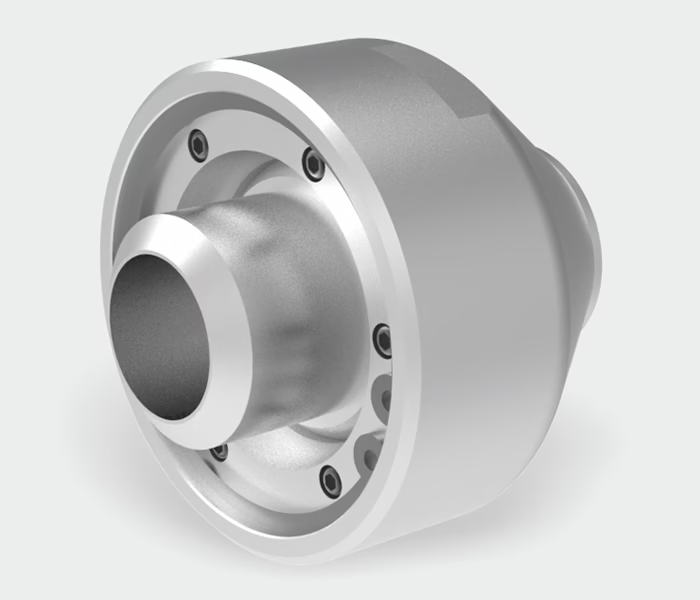

2. Stationary Housing (Stator)

Function: Anchors the swivel to the fixed structure and connects to the fluid inlet/outlet.

Materials: Heavy-duty metals like cast iron or forged steel for structural rigidity; may include corrosion-resistant coatings for marine or chemical applications.

Design Features:

Ports for fluid entry/exit (threaded, flanged, or quick-connect fittings).

Bearing seats support the rotating shaft.

3. Sealing System

The seal interface is the most critical component, as it prevents leakage between the stationary and rotating parts. Common seal types include:

Mechanical Seals:

Consists of a rotating face (usually tungsten carbide or silicon carbide) and a stationary face (carbon graphite or PTFE).

A thin fluid film between the faces lubricates the contact area, reducing friction and wear under high pressure.

O-Rings and Lip Seals:

Simple, cost-effective seals for low-pressure applications (e.g., <1000 PSI).

Made from elastomers like NBR (nitrile) for oil compatibility or FKM (Viton) for high-temperature resistance.

Labyrinth Seals:

Non-contacting seals that use a tortuous path to prevent solid particle ingress are often paired with primary seals in dirty environments.

4. Bearing System

Bearings support the rotating shaft, enabling smooth motion while handling radial and axial loads.

Key types include:

Ball Bearings: Suitable for moderate loads and speeds; common in general industrial applications.

Tapered Roller Bearings: Handle high radial and axial loads, ideal for heavy machinery like excavators.

Hydrostatic Bearings: Use a pressurized fluid film for frictionless rotation, critical in precision systems (e.g., aerospace).

5. Sealing Support Components

Spring Loaders: Maintain consistent seal face pressure to compensate for wear or thermal expansion.

Backup Rings: Prevent O-ring extrusion in high-pressure applications by reinforcing the seal.

Glands and Packing Boxes: House and secure the seals, ensuring proper alignment.

Design Considerations

When integrating a hydraulic swivel into a system, several factors must be considered:

1. Mounting Rigidity

A rigid mounting structure prevents flexing and misalignment, which can lead to operational issues such as chatter—a rapid, repetitive motion causing noise and potential damage. Enhancing the strength of mounting plates and torque arm assemblies can mitigate these problems.

2. Swivel Torque

The resistance to rotation, known as swivel torque, is influenced by factors like seal design, pressure levels, and lubrication. Understanding both static (breakaway) and dynamic torque values is essential for optimal performance.

3. Seal Design and Material

Selecting appropriate seal materials compatible with the hydraulic fluid and operating conditions (pressure, temperature) ensures durability and leak prevention.

4. Passage Configuration

Determining the number and arrangement of passages within the swivel is crucial for applications requiring multiple fluid channels.

Types of Hydraulic Swivel Joint and Applications

Hydraulic swivels are tailored to specific operational demands. Common variants include:

1. Single-Passage Swivels

Design: One fluid pathway for simple power transmission.

Applications: Agricultural machinery, conveyor systems.

2. Multi-Passage Swivels

Design: Multiple independent channels for transferring different media (e.g., oil, water, and electrical signals).

Applications: Offshore drilling rigs, where simultaneous control of hydraulic and pneumatic systems is required.

3. High-Pressure Swivels

Design: Reinforced seals and hardened steel bodies rated for 5,000+ PSI.

Applications: Mining equipment, naval stabilizers, and heavy-duty presses.

4. Industry-Specific Use Cases

Marine Engineering: Swivels in ship stabilizers and deck cranes ensure smooth operation in corrosive saltwater environments.

Aerospace: Lightweight aluminum swivels with titanium coatings are used in aircraft landing gear systems.

Step-by-Step Operational Process

Let’s break down the fluid transfer process in a hydraulic swivel during a typical operation:

1. Fluid Entry into the Stationary Housing

Pressurized fluid (e.g., hydraulic oil) enters the swivel through the stationary housing’s inlet port, which is connected to a fixed pipeline or hose.

The housing’s internal channels direct the fluid toward the seal interface.

2. Sealing Interface Dynamics

As the rotating shaft spins, the mechanical seal’s rotating face moves relative to the stationary face.

A thin film of fluid (created by the system’s pressure) lubricates the seal faces, reducing friction to near-zero levels (coefficient of friction ~0.05–0.1).

The spring loader ensures constant contact between the faces, adapting to minor axial movements or wear.

3. Bearing-Mediated Rotation

The rotating shaft is supported by bearings, which absorb radial forces (e.g., from misalignment) and axial forces (e.g., fluid pressure thrust).

Bearings are lubricated with grease or oil to minimize friction; in high-speed applications, synthetic lubricants with high thermal stability are used.

4. Fluid exits through the Rotating Shaft

After passing the seal interface, fluid travels through the rotating shaft’s internal bores to the outlet port, which connects to the rotating component (e.g., a hydraulic motor on a crane boom).

The design of these bores (diameter, smoothness) influences flow rate and pressure drop; larger bores reduce turbulence and energy loss.

5. Pressure and Leakage Control

The seal’s ability to withstand pressure depends on its “balance ratio”—the ratio of fluid pressure area to spring-loaded area. Balanced seals (common in high-pressure systems) equalize forces to prevent excessive wear.

In case of minor seal wear, the spring loader pushes the stationary face closer, maintaining a tight seal until maintenance is required.

Design Considerations for Optimal Performance

Engineers must tailor hydraulic swivels to specific operational demands. Key design factors include:

1. Pressure Rating

Working Pressure: The maximum continuous pressure the swivel can handle (e.g., 3000 PSI for mobile hydraulics, 10,000 PSI for oilfield equipment).

Burst Pressure: A safety margin (typically 2–3x working pressure) to withstand sudden surges.

2. Rotational Speed

Critical Speed: The speed at which vibrations become destructive; swivels must operate below this threshold (calculated using shaft geometry and bearing specs).

Balancing: High-speed swivels (e.g., >5000 RPM) require dynamic balancing to minimize vibration, often to ISO G2.5 standards.

3. Temperature Range

Media Temperature: Swivels must handle fluid temperatures, from cryogenic (-40°C) to high-heat (300°C for steam applications).

Material Selection:

High-temperature: Inconel shafts, graphite seals, and metal bellows for thermal expansion compensation.

Low-temperature: Ductile alloys (e.g., 304 SS) and FKM seals to prevent brittleness.

4. Media Compatibility

Fluid Type: Hydraulic oil, water, chemicals, or abrasive fluids dictate material choices:

Corrosive fluids: Stainless steel or titanium components, PTFE-lined seals.

Abrasive media: Tungsten carbide seal faces to resist erosion.

5. Environmental Factors

Dust and Debris: Labyrinth seals or protective boots to prevent particle ingress in construction or mining equipment.

Marine Environments: Corrosion-resistant coatings (e.g., zinc-nickel plating) and duplex stainless steel to combat saltwater exposure.

Common Applications of Hydraulic Swivel Joint

Hydraulic swivels are pivotal in diverse industries, each with unique operational requirements:

1. Construction and Heavy Machinery

Example: Excavators, cranes, and loaders use swivels to transfer hydraulic fluid to rotating booms, enabling 360° movement.

Key Requirements: High load capacity (tapered roller bearings), rugged seals (e.g., tungsten carbide mechanical seals), and resistance to dirt and vibrations.

2. Energy and Power Generation

Wind Turbines: Swivels in nacelles transfer hydraulic fluid to pitch-control systems, which adjust blade angles during rotation.

Hydroelectric Turbines: Seawater-resistant swivels manage cooling water flow in submerged generators.

3. Manufacturing and Automation

Robotic Arms: Compact swivels enable precise fluid transfer in high-speed robotic welding or material handling.

Injection Molding Machines: Swivels supply hydraulic oil to rotating mold tables, ensuring consistent pressure during cycles.

4. Oil and Gas Industry

Offshore Rigs: High-pressure swivels (up to 15,000 PSI) handle drilling fluids and control systems in rotating blowout preventers.

Refineries: Swivels in distillation columns manage steam and chemical flow in rotating agitators.

5. Agriculture and Forestry

Combine Harvesters: Swivels transfer hydraulic fluid to rotating cutting heads, enduring dust, moisture, and variable speeds.

Forestry Machines: Log loaders use swivels to operate grapples and saws on rotating booms.

Maintenance Best Practices

Proper maintenance is critical to ensuring a hydraulic swivel’s longevity and leak-free operation:

1. Regular Inspections

Visual Checks: Look for fluid leaks, seal face wear, or bearing play (axial movement >0.1mm indicates wear).

Vibration Analysis: Use a handheld vibrometer to detect unusual frequencies, signaling bearing damage or misalignment.

2. Lubrication Schedules

Bearings: Re-lubricate according to the manufacturer’s guidelines (e.g., every 100 hours for high-speed applications), using grease with the correct NLGI grade (typically 2 for moderate loads).

Seal Faces: Ensure the fluid film is maintained; avoid dry running, which causes catastrophic seal failure.

3. Replacement Strategies

Seals: Replace at recommended intervals (e.g., annually for harsh environments) or at the first sign of leakage.

Bearings: If vibrations exceed ISO 1940 G6.3 standards, replace bearings to prevent secondary damage to seals.

4. Installation Tips

Alignment: Use laser alignment tools to ensure the shaft is within 0.05mm/m of the stationary housing to avoid excessive radial loads.

Torque Specs: Follow manufacturer torque values for fittings to prevent thread stripping or seal distortion.

Choosing the Right Hydraulic Swivel Joint

When selecting a swivel, consider these steps:

Define Requirements: Pressure, speed, temperature, media, and environment.

Material Selection: Match components (seals, bearings, housing) to fluid and environmental factors.

Manufacturer Expertise: Choose suppliers with proven experience in your industry (e.g., Deublin for industrial swivels, Rothe Erde for heavy-duty applications).

Testing Standards: Ensure compliance with ISO 10766 (hydraulic rotary unions) or API 676 for oil and gas applications.

Future Trends in Hydraulic Swivel Design

Smart Swivels: Integrated sensors to monitor seal wear, temperature, and vibration, enabling predictive maintenance via IoT.

Eco-Friendly Materials: Biocompatible seals and recycled alloys to meet sustainability goals in the food and pharmaceutical industries.

Additive Manufacturing: 3D-printed components for custom geometries, reducing lead times and material waste.

Conclusion: The Silent Enabler of Rotational Hydraulics

A hydraulic swivel may seem like a small component, but its role in enabling fluid transfer during rotation is indispensable for modern industry. By understanding its working mechanism, key components, and design considerations, you can select, install, and maintain swivels that deliver reliable performance, even in the most demanding environments. Hydraulic swivels are essential components that enable the seamless transfer of hydraulic fluid between stationary and rotating parts in various machinery. Remember, the devil is in the details: pressure ratings, seal materials, and bearing choices can mean the difference between seamless operation and costly downtime.