How the HKS-XF Rotary Joint Optimizes LGT Slag Cooler Performance

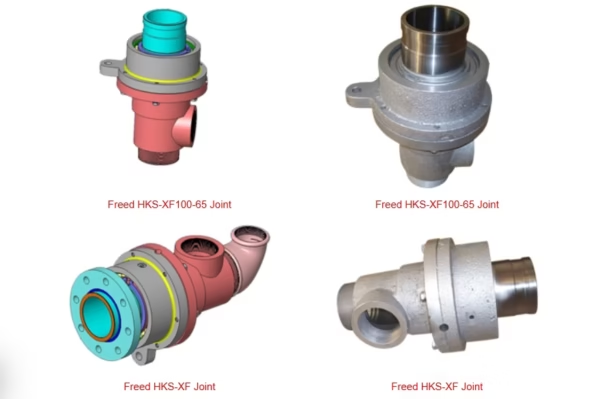

The LGT Drum Slag Cooler is a critical component in metallurgical and heavy industrial processes. It is designed to rapidly cool and solidify molten slag while minimizing energy consumption and environmental impact. At the heart of its efficiency lies the HKS-XF Rotary Joint Series, a specialized rotary union engineered for extreme thermal resistance, high-pressure fluid transfer, and seamless integration with slag handling systems. Designed specifically for drum slag coolers in steel plants, power stations, and waste management facilities. This series addresses critical challenges like thermal expansion, corrosion, and energy efficiency.

The LGT Drum Slag Cooler Special HKS-XF Rotary Joint Series has emerged as a game-changer in the industrial cooling sector. Particularly for applications involving high-temperature slag handling. As industries increasingly prioritize efficiency, durability, and sustainability, understanding the technical nuances of this advanced rotary joint becomes crucial. This article delves into the design, functionality, and real-world applications of the HKS-XF series. Exploring its role in optimizing drum slag cooler performance while addressing common challenges like thermal expansion, corrosion, and maintenance costs.

In modern industrial production, efficient and reliable equipment accessories are the key to ensuring the stable operation of the production line. Especially in the fields of electricity, chemical industry, etc., the LGT drum slag cooler is an important equipment for processing the residual slag after boiler combustion. Its performance directly affects the efficiency and safety of the entire energy conversion system. The HKS-XF rotary joint, as the core component connecting the internal and external pipelines of the LGT drum slag cooler, plays a vital role in ensuring heat energy transmission, reducing heat loss, and extending equipment life. This article will introduce the specifications and models of the HKS-XF rotary joint in detail.

Introduction to LGT Drum Slag Coolers and Rotary Joints

HKS-XF series rotary joints are specially designed for LGT drum slag coolers. They use high-performance sealing materials and precision manufacturing processes to ensure long-term stable operation under high temperature, high pressure, and high-speed rotation working environments. This series of rotary joints achieves leakage-free transmission of media through precise matching between the rotating body and the shell. Effectively avoiding reduced thermal efficiency and safety hazards caused by leakage.

Rotary joints are critical components in machinery that require fluid transfer between stationary and rotating parts. In drum slag coolers, these joints facilitate the circulation of cooling media (e.g., water, oil) to dissipate heat generated during slag solidification. The HKS-XF series stands out due to its custom-engineered design for high-temperature environments, making it ideal for steel plants, power generation facilities, and waste management industries.

LGT Drum Slag Coolers are pivotal in industries like steelmaking, where molten slag (a byproduct of smelting) must be cooled from 1,500°C to below 100°C for safe disposal or recycling. These systems rely on:

Rotary drum design

Slag is tumbled through a rotating drum while water or air is circulated for cooling.

Thermal efficiency

Minimizing heat loss while ensuring rapid cooling to prevent re-melting.

Integration with HKS-XF Rotary Joints

These joints enable continuous coolant transfer between stationary pipes and the rotating drum.

Technical Specifications of the HKS-XF Rotary Joint Series

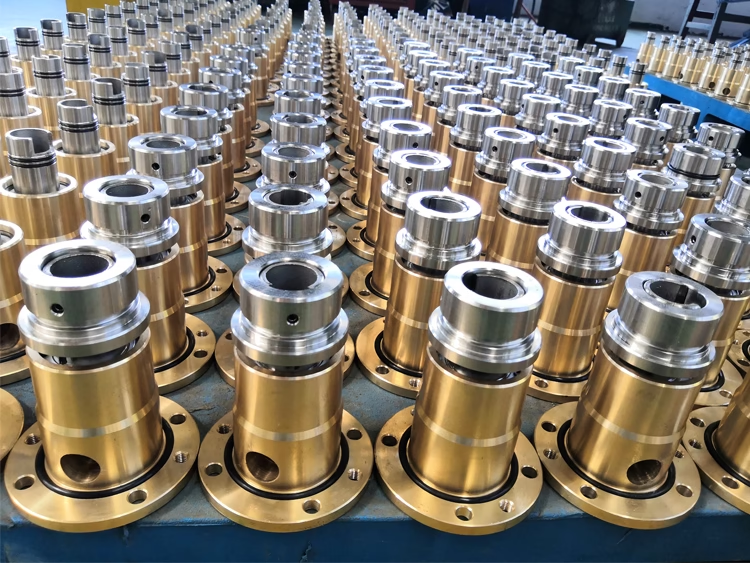

The HKS-XF series is engineered for durability and precision, with features tailored for slag coolers:

Core Components

Body Material: Stainless steel (SS316L) for corrosion resistance in acidic slag environments.

Seals: Multi-layered graphite/Viton seals rated for temperatures up to 300°C and pressures up to 40 bar.

Bearings: Tapered roller bearings with PTFE coatings to withstand axial loads from drum rotation.

Classification

HKS-XF 80A Slag Cooler Rotary Joint

Scope of application: Applicable to small to medium-sized LGT drum slag coolers and CFB boiler slag coolers. It is suitable for application scenarios with small processing volumes.

Main parameters: Maximum working pressure can reach 1.6MPa, maximum working temperature can reach 220°C, and the speed does not exceed 100rpm.

Features: Compact structure, easy installation, and low maintenance cost.

HKS-XF 90A to HKS-XF 100A Boiler Slag Cooler Rotary Joint

Upgrade features: As the model increases, the size and processing capacity of the applicable drum slag cooler also increase accordingly, the working pressure can reach 2.5MPa, the upper-temperature limit is increased to 260°C, and the upper-speed limit is increased to 150rpm.

Application areas: Widely used in the slag cooling system of medium and large thermal power plants and the chemical industry.

HKS-XF 125A to HKS-XF 150A boiler slag cooler rotary joint

Enhanced design: This series is designed for more severe working conditions. It not only has significant improvements in pressure, temperature, and speed (pressure up to 4.0MPa, temperature up to 280°C, speed up to 100rpm) but also has enhanced wear resistance and corrosion resistance, suitable for continuous high-intensity working environments.

Technological innovation: A special sealing structure is adopted to ensure that high sealing performance can be maintained under long-term operation.

HKS-XF 200A to HKS-XF 250A boiler slag cooler water-cooled rotary joint

High-end configuration: Customized for large and super-large LGT drum slag coolers, with a maximum working pressure of up to 6.0MPa, a temperature limit of up to 320°C, and a speed adaptation range extended to 100rpm. Features: Equipped with advanced self-lubricating bearings and reinforced sealing components to ensure stability and long life under extreme working conditions.

Design Innovations in the HKS-XF Series

Thermal Management

Heat Dissipation Channels: Internal grooves direct coolant flow to hotspots, reducing thermal stress.

Double-layered housing: Insulates against external heat while maintaining structural integrity.

Leak Prevention

Redundant Sealing System: Combines primary lip seals with secondary mechanical seals for fail-safe operation.

Real-Time Monitoring: IoT-enabled sensors track pressure, temperature, and wear, alerting operators to maintenance needs.

Features

Excellent sealing design, anti-leakage model

The HKS-XF slag cooler rotary joint knows that any leakage may cause safety hazards and production stagnation. This risk is especially critical when handling high-temperature slag in industrial processes. It adopts a multi-layer composite sealing structure designed to ensure tight sealing between rotating and stationary parts. The sealing ring, made of special material, fits tightly to the contact surfaces. This design not only withstands the high-temperature erosion caused by the slag cooling medium but also maintains excellent sealing. It performs reliably even under high-speed rotation conditions. Experimental data show that after thousands of hours of continuous operation, the leakage rate approaches zero. This rate is far lower than the industry average standard. Such performance lays a solid foundation for a stable heat exchange environment inside the slag cooler. It ensures safety and efficiency throughout the cooling process.

Efficient heat conduction, helping rapid cooling

Heat transfer efficiency is a key indicator to measure the quality of the rotary joint. The internal flow channel of this model has been carefully optimized, and the coolant can absorb the heat from the rotating cylinder wall to the greatest extent when it flows through. The unique spiral guide design increases the contact area and time between the coolant and the cylinder wall, which significantly improves the heat exchange rate. Compared with traditional joints, the HKS-XF cooling water rotary joint can shorten the slag cooling time by about 10%, greatly improve the working efficiency of the slag cooler, and meet the fast-paced production needs of modern industry.

Super wear-resistant, can cope with harsh working conditions

Inside the drum slag cooler, slag particles continuously wash the surface of the rotary joint as the drum rotates. Ordinary materials will soon wear and deform, leading to frequent equipment failures. The HKS-XF rotary joint uses a new type of carbide shell, which is several times harder than ordinary metals and can effectively resist the “thousands of grinding and hitting” of slag. At the same time, the key friction parts inside are inlaid with self-lubricating wear-resistant materials, which reduces wear and ensures smooth rotation, extends service life, and reduces the cost and downtime of frequent replacement of equipment parts.

Precise adaptation, convenient installation, and maintenance

To match the unique structure of the LGT drum slag cooler, the HKS-XF rotary joint follows the concept of combining standardization and customization from the beginning of its design. Its connection size precisely matches the interface of the slag cooler, and it can be quickly installed without complicated debugging; the modular internal structure makes daily maintenance and repair as simple as building blocks. Maintenance personnel only need to follow the operation manual to easily disassemble and replace worn parts, greatly shortening the equipment maintenance cycle and ensuring that the production line can resume full-load operation in the shortest time.

Applications in Industrial Slag Cooling

The HKS-XF series excels in demanding environments:

Steel Plants

Integrates with LGT coolers to process blast furnace slag, reducing disposal costs by 30%.

Copper Smelters

Handles abrasive slag with pH levels as low as 2.5, thanks to corrosion-resistant coatings.

Waste-to-Energy Facilities

Recovers heat from slag for power generation, supported by the joint’s high thermal efficiency.

Maintenance and Troubleshooting

Best Practices

Monthly Inspections: Check seal wear using ultrasonic thickness gauges.

Annual Overhauls: Replace bearings and recalibrate alignment to prevent vibration-induced leaks.

Common Issues

Seal Degradation: Caused by thermal cycling. Solution: Upgrade to silicon carbide seals for temperatures >300°C.

Bearing Failure: Often due to misalignment. Fix: Use laser alignment tools during installation.

Selection Guide

When you select a suitable HKS-XF rotary joint, you must comprehensively consider the specific working conditions of the drum slag cooler, including factors such as processing capacity, working pressure, temperature range, speed requirements, and on-site installation space. In addition, you must pay attention to how the medium type (such as whether it contains particulate matter) and environmental conditions (such as a corrosive environment) influence the selection of rotary joint materials and sealing materials.

Type HK Rotary Joint Usage & Maintenance Handbook

Single Flow type HK rotary joint with quick-release flange

The work before installing the rotary joint

Before installing the rotary joint, please remove all scale and other dirt from the pipe and cylinder. The dirty media can reduce the service life of the rotary joint.

Installation of a quick-release nipple

Place the quick-release flange (1) and split wedge on the nipple, place the nipple into the pilot of the journal flange, and tighten bolts evenly on the quick-release flange so that the space between the quick-release flange (1) and the journal flange is even.

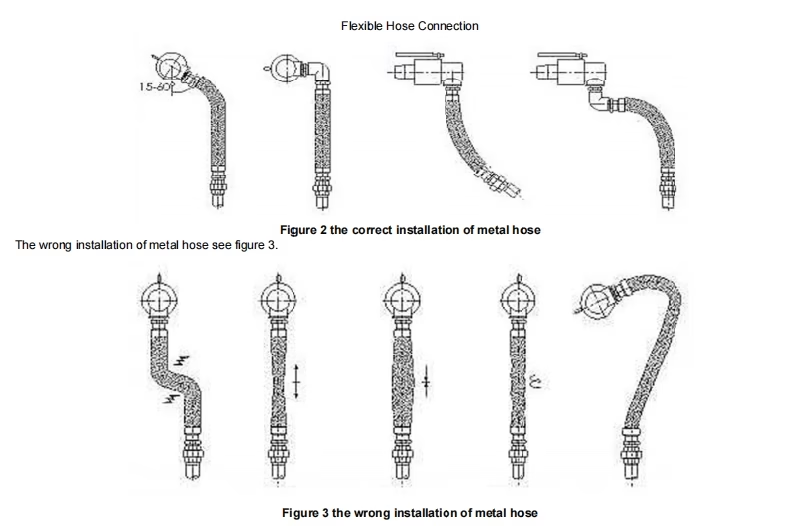

Flexible Hose Connection

Given your rotary joint application, choose a metal hose with ratings able to sustain the flow media. When connecting the rotary joint to the fixed pipe. The flexible hose (2) should be installed as close to the rotary joint as possible, in a relaxed condition, neither stretched nor compressed. You should strongly support the hose to avoid overloading the bearings of the rotary joint when you have an unusually long run of hose. For the correct installation of the metal hose, see Figure 2.

Conclusion

The HKS-XF Rotary Joint Series is a cornerstone of modern LGT Drum Slag Coolers, offering unmatched reliability in extreme conditions. HKS-XF series rotary joints have shown incomparable advantages in LGT drum slag cooler applications with their excellent performance, wide applicability, and high reliability. By accurately matching different models and specifications, they can effectively improve the overall efficiency and safety of the slag cooling system and are indispensable high-performance accessories in modern industrial production. When choosing, users should fully consider their actual needs and make reasonable selections to achieve the best use effect.

The LGT Drum Slag Cooler Special HKS-XF Rotary Joint Series represents a paradigm shift in industrial cooling technology. By combining innovative design, material science, and energy efficiency, it addresses critical challenges in high-temperature environments. For companies aiming to enhance productivity, reduce operational costs, and meet sustainability goals, the HKS-XF series is a strategic investment worth exploring.

In the journey of industry moving towards efficient, green, and safe development, the HKS-XF rotary joint dedicated to the LGT drum slag cooler has become a powerful assistant for many companies to optimize production processes, reduce energy consumption, and improve efficiency due to its outstanding performance in all aspects such as sealing, heat conduction, wear resistance, and adaptability. It continues to inject strong momentum into the field of industrial thermal management and help the industry take off.