Thermal Oil Rotary Unions: Safe & Reliable Heat Transfer Solutions

In industrial applications where thermal oil is used for heating or cooling, Thermal oil rotary unions play a critical role in maintaining efficient and reliable fluid transfer between stationary and rotating components. These devices are essential for industries such as plastics manufacturing, chemical processing, and food production, where high temperatures and pressures are common. This guide explores the design, applications, maintenance, and selection criteria for thermal oil rotary unions, supported by industry insights and technical specifications.

Understanding Thermal Oil Rotary Unions

1.1 Definition and Function

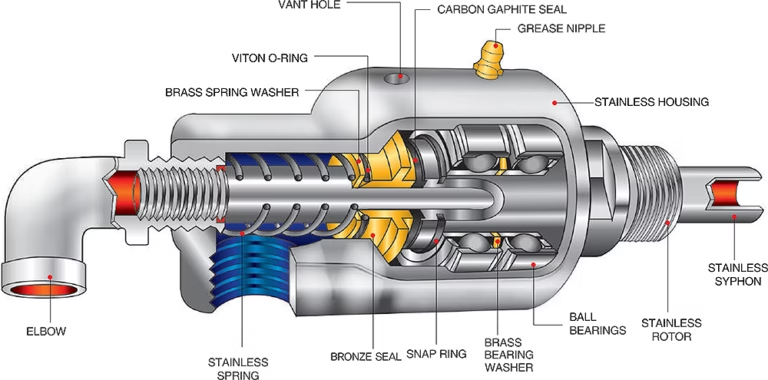

A thermal oil rotary union, also known as a rotating joint or swivel union, is a mechanical device that enables the leak-free transfer of thermal oil between a stationary supply line and a rotating component, such as a drum or cylinder. Its primary function is to maintain a stable connection while accommodating rotational movement, high temperatures (up to 450°F), and pressure surges. Key components include:

Seals: Typically made of carbon, graphite, or PTFE for heat resistance and low friction.

Bearings: Deep-groove ball bearings or self-aligning bearings to support rotational movement.

Housing: Constructed from stainless steel or cast iron to withstand harsh environments.

1.2 Working Principles

Thermal oil rotary unions use mechanical seals to prevent leaks while allowing rotation. For example, Deublin’s Type CSO union features balanced mechanical seals that reduce wear in high-speed applications. The design ensures thermal oil flows through the union without interruption, even under extreme conditions.

Types of Thermal Oil Rotary Unions

2.1 Single-Passage vs Multi-Passage

Single-Passage: Ideal for simple applications requiring a single fluid path, such as basic heating systems.

Multi-Passage: Capable of handling multiple fluids simultaneously, common in complex processes like extrusion or calendaring.

2.2 Specialized Designs

Self-Aligning Swivels: Reduce hose stress and leaks in angular piping applications.

Duo-Flow Unions: Feature dual sight glasses to monitor condensate flow, critical for paper and textile drying.

High-Pressure Models: Rated for pressures up to 20,000 psi, suitable for offshore or chemical processing

Applications Across Industries

3.1 Plastics Manufacturing

Rotary unions are used in injection molding machines and extruders to maintain precise temperature control. For example, Orbinexus offers custom solutions for chill rolls, ensuring consistent cooling.

3.2 Chemical Processing

In reactors and mixers, thermal oil rotary unions handle corrosive fluids and high temperatures. Deublin’s Type CRO union, with iron casings, withstands temperatures up to 450°F.

3.3 Food and Beverage

Used in baking ovens and pasteurization systems, these unions ensure safe and efficient heat transfer. Chesterton highlights their role in radar cooling systems, where reliability is critical.

3.4 Renewable Energy

In solar thermal plants, rotary unions facilitate heat transfer in parabolic trough systems. DirectIndustry lists models like the TJ-10871, designed for concentrated solar power

Key Design Considerations

4.1 Material Selection

Seals: Carbon graphite for shock resistance, PTFE for low friction.

Housing: Stainless steel (316L) for corrosion resistance, cast iron for high-pressure applications.

4.2 Technical Specifications

Temperature Range: Up to 450°F for standard models; specialized unions handle higher temperatures.

Pressure Ratings: 150–300 psi for most applications; high-pressure variants reach 20,000 psi.

Rotational Speed: Typically 0–1,000 rpm, though some designs support higher speeds.

4.3 Customization Options

Manufacturers like Kadant Johnson offer custom solutions for unique requirements, such as large coaxial designs for solar power plants.

Installation and Maintenance Best Practices

Proper installation and proactive maintenance are critical to maximizing the lifespan and reliability of rotary joints, especially in high-stress industrial environments. Below is a detailed breakdown of best practices, expanded to include technical specifications, practical examples, and actionable steps for each phase of the lifecycle.

5.1 Installation Guidelines

5.1.1 Flexible Hose Integration

Why It Matters: Rigid piping can introduce mechanical stress during rotational motion, leading to premature seal or bearing failure.

Material Selection: Opt for braided stainless steel hoses with a minimum burst pressure rating 4x the operating pressure (e.g., 3,000 PSI-rated hoses for 750 PSI systems). These offer 80% better resistance to vibration-induced fatigue compared to rubber hoses.

Length and Routing: Ensure hoses have a 10–15% slack to accommodate radial movement without tension. Avoid sharp bends (maintain a bend radius ≥ 3x hose diameter) to prevent kinking, which can restrict flow and create pressure surges.

Connection Types: Use swivel fittings at both ends of the hose to eliminate torsional stress on the rotary joint’s inlet/outlet ports. Threaded connections should be sealed with PTFE tape (3–5 wraps) or anaerobic sealant for gas-tight joints.

5.1.2 Precision Alignment Procedures

Alignment Tolerances: Misalignment exceeding 0.002 inches per inch of shaft length can increase seal wear by 300%.

Tools: Use laser alignment systems (e.g., Fluke 830) to measure angular (≤0.05°) and parallel (≤0.005 inches). For smaller systems, dial indicators with a resolution of 0.001 inches can be used.

Adjustment Steps:

Secure the stationary housing to the equipment frame using grade 8 bolts with lock washers.

Rotate the shaft 360°, measuring runout at the seal face (target ≤0.003 inches).

Shim the housing with stainless steel shims (0.001–0.010 inches thick) to correct horizontal/vertical misalignment.

Re-torque mounting bolts to the manufacturer’s specification (e.g., 50–70 ft-lbs for M12 bolts).

5.1.3 Seal Wear Monitoring Systems

Built-in Indicators: Modern rotary joints feature visual or digital wear sensors to enable predictive maintenance.

Visual Indicators: Colored wear bands (e.g., red zone at 2mm material loss) on carbon-graphite seal faces signal replacement needs. Transparent inspection windows allow direct visual checks without disassembly.

Digital Solutions: Integrate proximity sensors to measure seal face deflection (threshold: >0.5mm movement indicates face separation). Wireless IoT sensors can transmit real-time data to maintenance platforms, triggering alerts when wear rates exceed 0.1mm/month.

5.2 Preventive Maintenance Protocols

5.2.1 Scheduled Inspections (Daily/Weekly/Monthly)

Daily Checks:

Visually inspect for drips or wet spots around the housing (leakage >5 drops/min requires immediate action).

Use a stethoscope to listen for abnormal bearing noise (e.g., grinding indicates raceway damage, squealing signals lubrication failure).

Weekly Checks:

Measure the operating temperature with an infrared thermometer (normal range: ≤150°F for oil-lubricated bearings; ≥200°F signals overheating). – Record rotational torque using a torque wrench (an increase of 20% from baseline indicates seal friction issues).

Monthly Checks:

Perform a full system pressure test (1.5x operating pressure for 30 minutes) to validate seal integrity.

Inspect lubricant color/consistency—cloudy grease or metallic flakes indicate bearing wear or contamination.

5.2.2 Lubrication Strategies

Bearing Types vs. Lubricants:

Roller Bearings: Use high-temperature grease (NLGI grade 2, ISO VG 220 base oil) with a dropping point ≥500°F (e.g., Mobilith SHC 220), applied every 250 operating hours in high-speed applications (≥3,000 RPM).

Bushing Bearings: For self-lubricating graphite bushings, ensure ambient humidity ≥30% to maintain lubricity; in dry environments, apply food-grade mineral oil (1–2 drops/week) to prevent metal-to-metal contact.

Lubrication Techniques: Use a grease gun with a pressure relief valve (max 1,000 PSI) to avoid overpacking, which can cause heat buildup. Wipe excess grease from fitting ports to prevent dust accumulation.

5.2.3 Seal Replacement Schedules

Environment-Specific Intervals:

High-Stress Applications (e.g., steam at 500°F, 1,000 PSI): Replace dual mechanical seals every 6 months. Use seals with tungsten carbide faces (hardness ≥85 HRC) and PTFE bellows for chemical resistance.

Standard Industrial Use (e.g., water at 150 PSI, 70°F): Annual replacement is sufficient. Inspect O-rings for compression set (flatness >20% of original cross-section requires replacement); upgrade to FKM (Viton) O-rings for oil-based media.

Critical Maintenance Steps:

1. Clean the seal chamber with isopropyl alcohol to remove debris.

2. Apply a thin film of anti-seize compound to the shaft shoulder to facilitate future disassembly.

3. Use a seal installation tool to avoid damaging the delicate seal faces during insertion.

5.3 Troubleshooting Common Issues

5.3.1 Leakage Diagnosis and Resolution

Root Causes & Solutions:

Worn Seal Faces: Replace seals; inspect shaft surface roughness (Ra ≤1.6μm is ideal; >3.2μm causes accelerated wear). Polish the shaft with 800-grit sandpaper if scored.

Misalignment: Re-align using laser tools; check for frame deflection under load (add gussets to strengthen mounting structures if deflection >0.01 inches).

Material Compatibility: Switch to silicon carbide seals for abrasive media (e.g., wastewater with solids); use EPDM O-rings for glycol-based fluids to prevent swelling.

5.3.2 Overheating Analysis

Potential Culprits:

Insufficient Cooling: For water-cooled seals, ensure flow rate ≥2 GPM and check for scale buildup (use descaling solution with pH 4–5 annually).

Blocked Fluid Paths: Clean strainers (40–100 mesh) upstream of the joint; inspect for debris in housing ports (use borescope for hard-to-reach areas).

Bearing Failure: Replace bearings with a higher load rating (L10 life ≥10,000 hours for continuous operation); upgrade to sealed bearings in dusty environments.

5.3.3 Bearing Failure Prevention

Failure Modes & Mitigation:

Lubrication Starvation: Install automatic lubrication systems (e.g., Lincoln SureLube) with timed grease injection (every 4 hours in high-duty cycles).

Contamination: Add breather filters (3μm absolute rating) to bearing housings; use labyrinth seals to prevent ingress of dust/water.

Overloading: Recalculate load capacity using the formula: C = P*n*L, where C is the dynamic load rating, P is the equivalent radial load, n is the speed (RPM), and L is the desired life (10^6 revolutions). Upgrade to tapered roller bearings for combined radial-axial loads exceeding 50% of rated capacity.

Following these expanded guidelines, operators can reduce unplanned downtime by up to 40%, extend component life by 25–30%, and ensure consistent performance even in the most demanding industrial environments. Always consult the manufacturer’s manual for application-specific tolerances and maintenance intervals.

Choosing the Right Rotary Union

6.1 Key Selection Criteria

Media Compatibility: Ensure materials resist thermal oil degradation.

Temperature/Pressure Ratings**: Match to operational conditions.

Industry Standards**: Look for certifications like ISO 9001 or ASME.

6.2 Cost vs. Performance

While some suppliers offer units as low as $15, premium brands like Deublin provide higher durability and longer lifespan. Consider the total cost of ownership, including maintenance and downtime.

6.3 Case Studies

Packaging Industry: Kadant Johnson’s LJ X™ union improved runnability in corrugators, increasing speed by 100 FPM.

Offshore Oil: High-pressure unions from LPR Global withstand extreme conditions in FPSO systems.

Industry Trends and Innovations

7.1 IoT Integration

Smart rotary unions with sensors monitor performance in real-time, reducing downtime. Moog’s hybrid designs combine fluid transfer with electrical slip rings for robotics.

7.2 Sustainable Materials

Manufacturers are adopting eco-friendly materials like recycled stainless steel and biodegradable lubricants.

7.3 Market Growth

The global rotary union market is projected to grow at a 6.5% CAGR through 2034, driven by automation and renewable energy demand.

FAQs related to Rotary Unions for Thermal Oil

1. What temperature ranges can thermal oil rotary unions handle?

Thermal oil rotary unions are designed to operate in high-temperature environments, typically ranging from -20°C to 300°C (-4°F to 572°F). The exact temperature limit depends on the union’s construction materials (e.g., stainless steel, carbon steel) and seal types (e.g., nitrile, Viton, or metal seals). Exceeding the rated temperature may degrade seals or cause leaks, so consulting the manufacturer’s specifications is critical for safe operation.

2. Why are stainless steel components preferred in thermal oil rotary unions?

Stainless steel (e.g., 316L grade) is commonly used due to its corrosion resistance, strength at high temperatures, and compatibility with thermal oils. Unlike carbon steel, it minimizes oxidation and pitting in harsh thermal environments. Additionally, stainless steel ensures long-term durability, reducing maintenance needs in applications like plastic molding or chemical processing where thermal oil may contain additives.

3. How often should thermal oil rotary unions be serviced or inspected?

Service intervals depend on operating conditions, temperature, and rotational speed. As a general guideline, inspect unions every 3-6 months for signs of wear (e.g., leaks, excess noise) or contamination. Replace seals or bearings annually or sooner if operating continuously at high temperatures. Regular maintenance prevents costly downtime and ensures efficient heat transfer.

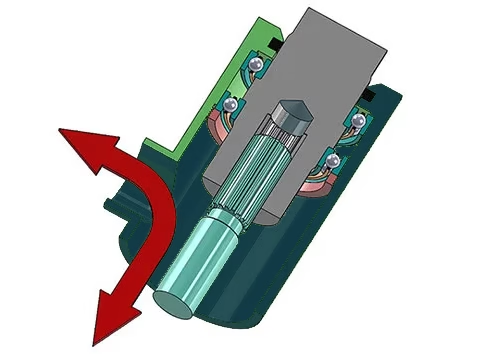

4. Can thermal oil rotary unions be used in bidirectional rotation applications?

Yes, many thermal oil rotary unions are engineered for bidirectional rotation (clockwise and counterclockwise). However, this depends on the union’s design, such as balanced seal configurations or dual-row bearings. For bidirectional use, specify this requirement when ordering to ensure the union includes features like symmetric sealing elements and robust bearing support to handle reversed loads without performance loss.

Conclusion

Thermal oil rotary unions are indispensable for industries reliant on high-temperature fluid transfer. By selecting the right design, following maintenance protocols, and embracing innovations like IoT integration, operators can optimize efficiency and reduce costs. Whether in plastics, chemicals, or renewable energy, these devices ensure seamless operation in challenging environments.

Call to Action

For expert advice on thermal oil rotary unions, contact our team or explore our product catalog for customized solutions.