Unveiling the Meaning and Significance of Maier Rotary Joint DQ Series

In the intricate world of industrial machinery and fluid transfer systems, rotary joints play a pivotal role. These unassuming components are the linchpin that enables the seamless transfer of fluids, gases, and even electrical power between stationary and rotating parts of a machine. Among the diverse range of rotary joints available in the market, the Maier Rotary Joint DQ Series has emerged as a popular choice for many industries. But what exactly does “Maier Rotary Joint DQ Series” mean? In this in-depth blog post, we will embark on a comprehensive exploration to uncover the meaning, features, applications, and significance of the DQ series rotary joints.

Understanding Rotary Joints: The Basics

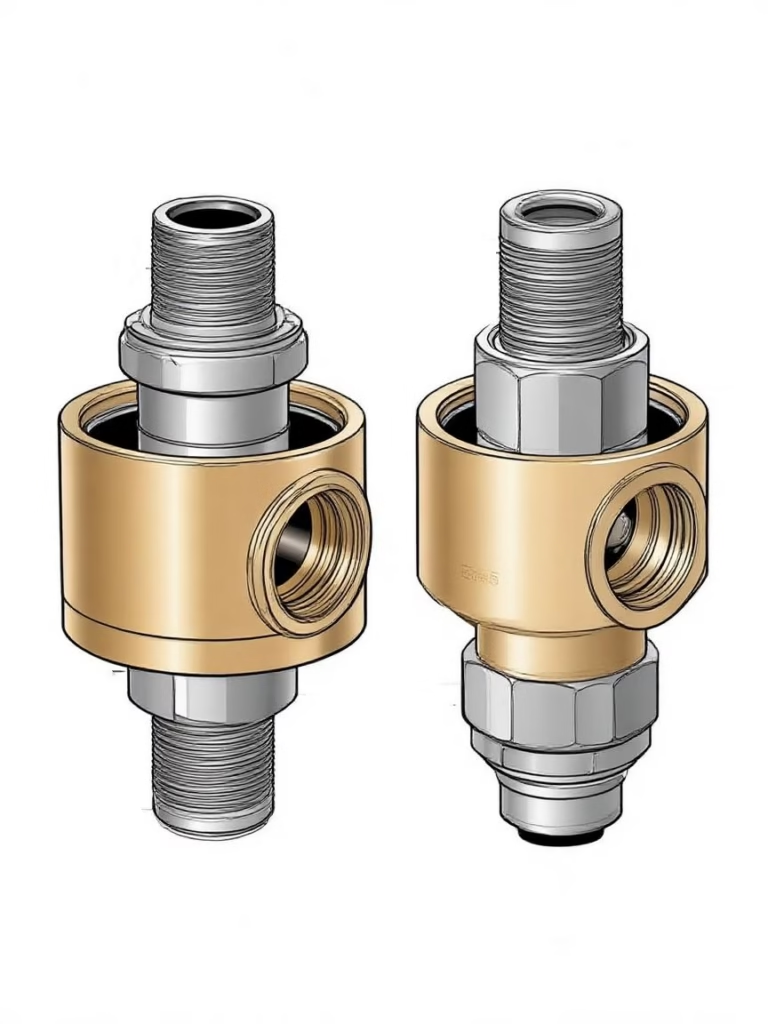

Before delving into the specifics of the Maier Rotary Joint DQ Series, it is essential to have a solid understanding of what rotary joints are and how they function. A rotary joint, also known as a swivel joint or swivel union, is a mechanical device for transmitting a fluid medium from a stationary source to a rotating component. It allows for continuous rotation while maintaining a leak-proof connection, enabling the transfer of various substances such as water, steam, oil, hydraulic fluid, and compressed air.

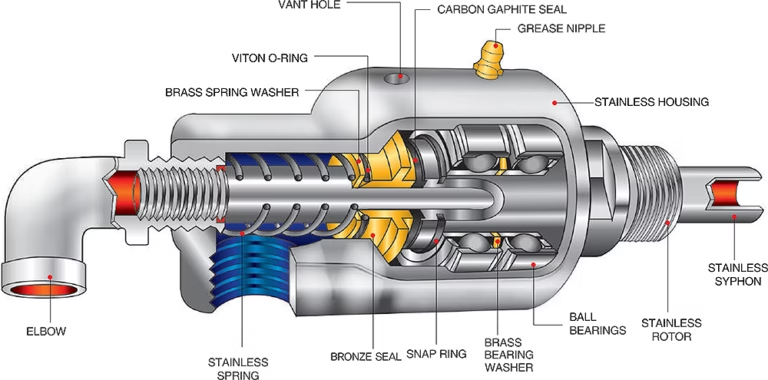

The fundamental components of a rotary joint typically include a stationary housing, a rotating shaft, seals, and bearings. The stationary housing connects to the fluid source, while the rotating shaft attaches the rotating part of the machine. Seals play a crucial role in preventing leakage, keeping the fluid within the joint, and directing it properly to its destination. Bearings support the rotating shaft, reducing friction and wear, and allowing for smooth and efficient rotation.

Rotary joints find applications in a wide variety of industries, including manufacturing, food and beverage, paper and pulp, oil and gas, and automotive. They are in equipment such as printing presses, packaging machines, textile looms, injection molding machines, and wind turbines, among others. The ability of rotary joints to facilitate the transfer of fluids in rotating systems is essential for the proper functioning and productivity of these industrial machines.

Deciphering the Maier Rotary Joint DQ Series

The “DQ” in “Rotary joints DQ series” is typically a model or series designation assigned by the manufacturer. While different manufacturers may use the “DQ” label, the specific meaning and characteristics associated with this series can vary. However, in general, the DQ series rotary joints stand out from other types because they offer certain common features and qualities.

Design and Construction

DQ series rotary joints are often designed with precision and durability in mind. The housing and shaft are typically made from high-quality materials such as stainless steel, carbon steel, or alloy steel, depending on the application requirements. Stainless steel is a popular choice due to its excellent corrosion resistance, making it suitable for applications involving aggressive fluids or harsh environments.

The seals used in the Maier Rotary Joint DQ Series are of critical importance. Manufacturers usually make them from advanced materials such as fluorocarbon rubber (Viton), nitrile rubber (NBR), or polytetrafluoroethylene (PTFE). These materials offer excellent chemical resistance, high-temperature tolerance, and low-friction properties, ensuring a reliable and long-lasting seal. The seal design may vary, with some DQ series joints featuring multiple-lip seals or cartridge-type seals for enhanced sealing performance.

Bearings in Maier Rotary Joint DQ Series are carefully selected to withstand the rigors of continuous rotation. They are often precision ball bearings or roller bearings, which provide smooth and stable rotation while minimizing friction and wear. Engineers optimize the bearing design to support the load requirements of the specific application, ensuring the joint’s longevity and reliability.

Performance Characteristics

One of the key features of the Maier Rotary Joint DQ Series is its ability to handle a wide range of operating conditions. Manufacturers typically design them to operate at high rotational speeds, often ranging from a few hundred to several thousand RPM, depending on the model and size. This design makes them suitable for applications that require rapid rotation, such as high-speed printing presses or centrifuges.

In terms of pressure and temperature capabilities, DQ series rotary joints are engineered to handle varying levels. They can withstand high-pressure fluids, with some models capable of operating at pressures up to several hundred pounds per square inch (PSI) or more. Similarly, they can handle a wide temperature range, from sub-zero temperatures to high-temperature applications involving steam or hot oils. For example, some manufacturers rate DQ series joints for continuous operation at temperatures up to 300°C or higher.

The flow capacity of DQ series rotary joints is also an important consideration. Manufacturers design these joints to facilitate the efficient transfer of fluids, offering different flow rates based on size and design. They optimize the internal passageways to minimize fluid resistance and ensure smooth, unobstructed flow.

Versatility and Customization

Another significant aspect of the DQ series is its versatility. These rotary joints are available in a wide range of sizes, configurations, and connection types to meet the diverse needs of different industries and applications. They can be customized to accommodate specific fluid types, operating conditions, and installation requirements.

For example, DQ series rotary joints can be designed with different types of end connections, such as threaded connections, flanged connections, or quick-disconnect couplings. This allows for easy integration into existing systems and simplifies the installation process. Additionally, some manufacturers offer the option to customize the joint’s internal components, such as seals and bearings, to suit the unique demands of a particular application.

DQ Series vs. Competitors: Key Differentiators

Temperature Resistance: DQ joints often handle up to 350°C (662°F).

Pressure Ratings: Up to 300 bar (4,350 psi) in industrial models.

Maintenance: Tool-free disassembly for quick service.

Applications of DQ Series Rotary Joints

The versatility and performance of DQ series rotary joints enable their use across diverse industries.

Manufacturing Industry

In manufacturing, DQ series rotary joints equip injection molding machines, blow molding machines, and extruders. During injection molding, the joint transfers hydraulic fluid or cooling water to rotating molds, maintaining precise temperatures and operational efficiency. For blow molding, it delivers compressed air to rotating mandrels, which is critical for shaping plastic components.

Metalworking machinery such as lathes, milling machines, and grinders incorporates DQ series joints to supply coolant or lubricant to cutting tools. This enhances tool lifespan and product quality. Their high-speed capability suits applications requiring rapid tool rotation.

Food and Beverage Industry

Meeting stringent hygiene standards, DQ series rotary joints serve filling machines, capping machines, and food processing lines. In filling systems, they route beverages, sauces, or oils to rotating nozzles. Corrosion-resistant materials and food-grade seals prevent product contamination during transfers.

Thermal processing applications—cooking, baking, or pasteurization—use DQ series joints to channel steam or hot water to rotating equipment. This ensures exact temperature control, which is vital for food safety and quality.

Paper and Pulp Industry

DQ series rotary unions play a pivotal role in paper production. On paper machines, they transfer steam, water, and lubricating oil to rotating cylinders and rolls. Their high-temperature and high-pressure tolerance suits the demanding conditions of mills.

For instance, in a paper machine’s drying section, rotary joints deliver steam to drying cylinders, removing moisture from the paper. Their reliable sealing and smooth operation optimize steam efficiency, cutting energy use and enhancing paper quality.

Oil and Gas Industry

Designed for harsh environments, DQ series rotary unions withstand extreme conditions in drilling rigs, pumps, and compressors. During drilling, they transfer drilling fluid (“mud”) from stationary systems to rotating drill strings, cooling bits, clearing cuttings, and regulating pressure.

Constructed from duplex stainless steel or alloy steel. These joints handle high-pressure fluids and temperatures, ensuring reliability in offshore and onshore operations.

Automotive Industry

The automotive sector uses DQ series rotary unions in manufacturing and testing. In component production (engine blocks, transmissions, wheels). They supply coolant, lubricant, or hydraulic fluid to rotating machinery, ensuring equipment durability and functionality.

Dynamometers for vehicle testing utilize these joints to transmit power and fluids between stationary test rigs and rotating wheels. Enabling precise performance evaluations.

Benefits of Using DQ Series Rotary Joints

The adoption of DQ series rotary joints offers several benefits to industries and businesses.

Reliability and Durability

The high-quality materials, precision design, and robust construction of DQ series rotary joints contribute to their reliability and durability. These joints are engineered to withstand the rigors of continuous operation in demanding industrial environments, reducing the risk of breakdowns and downtime. The use of advanced seals and bearings ensures a long service life, minimizing the need for frequent replacements and maintenance.

Improved Efficiency

By facilitating the smooth and efficient transfer of fluids, DQ series rotary joints help to improve the overall efficiency of industrial processes. The optimized internal design of the joints reduces fluid resistance, allowing for higher flow rates and better performance. This can lead to increased productivity, reduced energy consumption, and lower operating costs.

Cost – Effectiveness

Although DQ series rotary joints may have a relatively higher upfront cost compared to some basic rotary joints, their long-term cost-effectiveness is evident. Their durability and low maintenance requirements result in fewer replacement parts and less frequent repairs, saving businesses money in the long run. Additionally, the improved efficiency and productivity enabled by these joints can lead to increased revenue and a better return on investment.

Compatibility and Ease of Installation

The wide range of sizes, configurations, and connection types available in DQ series rotary joints makes them highly compatible with existing industrial systems. They can be easily integrated into new or existing machinery, and the installation process is relatively straightforward. This reduces the time and effort required for installation and commissioning, minimizing disruption to production.

Case Studies: Real-World Applications of DQ Series Rotary Joints

To further illustrate the practical significance of DQ series rotary joints, let’s take a look at some real-world case studies.

Case Study 1: Printing Press Upgrade

A large-scale printing company was experiencing frequent downtime and leakage issues with its existing rotary joints in its high-speed printing presses. The company decided to upgrade to DQ series rotary unions. After installation, the new joints were able to handle the high rotational speeds and pressure requirements of the printing presses. The advanced seal design eliminated leakage problems, and the precision-engineered bearings reduced friction, resulting in smoother operation. As a result, the printing company saw a significant reduction in downtime, improved print quality, and increased productivity.

Case Study 2: Food Processing Plant Expansion

A food processing plant was expanding its production capacity and needed reliable rotary joints for its new filling and cooking equipment. DQ series rotary joints were chosen due to their food-grade materials and high-temperature capabilities. The joints were customized to fit the specific requirements of the plant’s equipment, with special end connections and seal configurations. Since the installation, the plant has been able to operate its new equipment without any contamination issues, and the precise temperature control enabled by the DQ series joints has improved the quality of its food products.

Choosing the Right DQ Series Rotary Joint

When selecting a DQ series rotary union for a specific application, several factors need to be considered.

Operating Conditions

The operating conditions, including temperature, pressure, rotational speed, and fluid type, are crucial considerations. It is essential to choose a rotary joint that for the specific operating conditions of the application to ensure reliable performance and prevent premature failure.

Fluid Compatibility

The compatibility of the rotary joint’s materials with the fluid being transferred is of utmost importance. Different fluids have different chemical properties, and using a joint with materials that are not compatible can lead to corrosion, seal degradation, and leakage. Manufacturers typically provide information on the fluid compatibility of their DQ series rotary joints, which should be carefully reviewed before making a selection.

Size and Configuration

The size and configuration of the rotary joint need to match the requirements of the equipment and the installation space. Factors such as the diameter of the shaft, the length of the joint, and the type of end connections should be considered. Customization options may also be available to ensure a perfect fit for the specific application.

Manufacturer Reputation and Support

Choosing a reputable manufacturer is essential for obtaining high-quality DQ series rotary joints and reliable after-sales support. A well-established manufacturer will have a proven track record of producing reliable products and will be able to provide technical assistance, maintenance advice, and replacement parts when needed.

Maintenance & Longevity – Extending DQ Series Lifespan

Preventive Maintenance Checklist

Daily: Inspect for leaks and check the temperature.

Weekly: Lubricate bearings (if applicable).

Annually: Replace seals and O-rings.

Pro Tip: Use a thermal camera to detect hotspots indicative of seal failure.

Repair vs. Replace: Cost-Benefit Analysis

Repair: Cost-effective for minor leaks (seal replacement: 200–500).

Replace: Justified for outdated models or frequent breakdowns.

Conclusion

In conclusion, the “Rotary joints DQ series” represents a range of high-performance rotary joints. That offers a combination of reliability, durability, versatility, and efficiency. These joints play a vital role in various industries. Facilitating the seamless transfer of fluids, gases, and power in rotating systems. Understanding the meaning, features, applications, and benefits of DQ series rotary joints. It is essential for industries looking to optimize their processes, improve productivity, and reduce costs.

When considering the use of DQ series rotary joints. It is crucial to carefully evaluate the specific requirements of the application and select the right joint. Based on factors such as operating conditions, fluid compatibility, size, and manufacturer reputation. By making an informed choice, businesses can ensure the long-term success and reliability of their industrial systems. Reaping the many benefits that DQ series rotary joints have to offer. As technology continues to evolve, we can expect further advancements in the design and performance of DQ series rotary joints. Opening up new possibilities for industrial applications in the future.