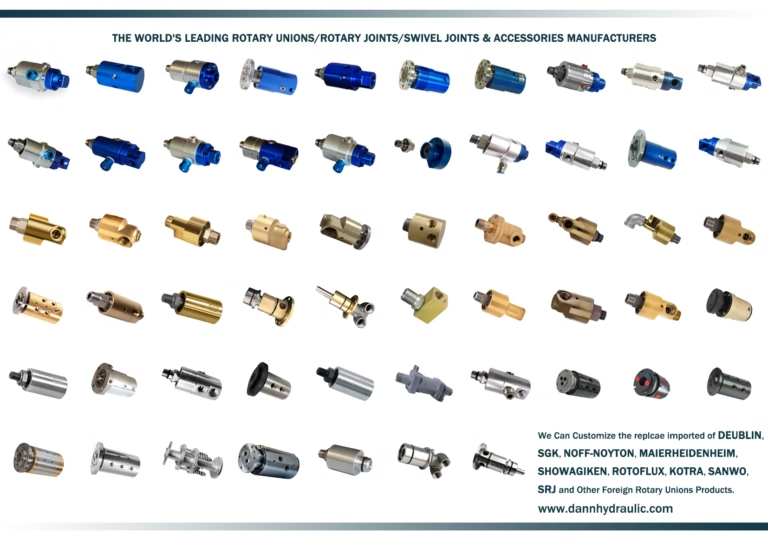

Rotary Unions & Joints Manufacturer

Rotary Unions & Joints: Unlocking the Secrets of Fluid Transfer in Industrial Systems

In the complex and dynamic world of industrial machinery, seamlessly transferring fluids, gases, and electrical power between stationary and rotating components is crucial for the efficient operation of countless processes. Rotary unions and joints are the unsung heroes making this possible. These unassuming yet essential devices play a vital role in a wide range of industries, from manufacturing and food processing to oil and gas and aerospace. In this comprehensive blog post, we will delve deep into the world of rotary unions and joints, exploring their definitions, types, working principles, applications, benefits, and much more. Whether you’re an engineer, a maintenance professional, or simply curious about industrial technology, this guide will provide you with a detailed understanding of these critical components.

What are Rotary Unions and Joints?

At their core, rotary unions and joints are mechanical devices facilitating the transfer of various media, such as liquids, gases, and even electrical signals, between stationary and rotating parts of a machine. While people often use the terms “rotary union” and “rotary joint” interchangeably, there are some subtle differences in their usage and design in certain contexts.

Rotary Unions

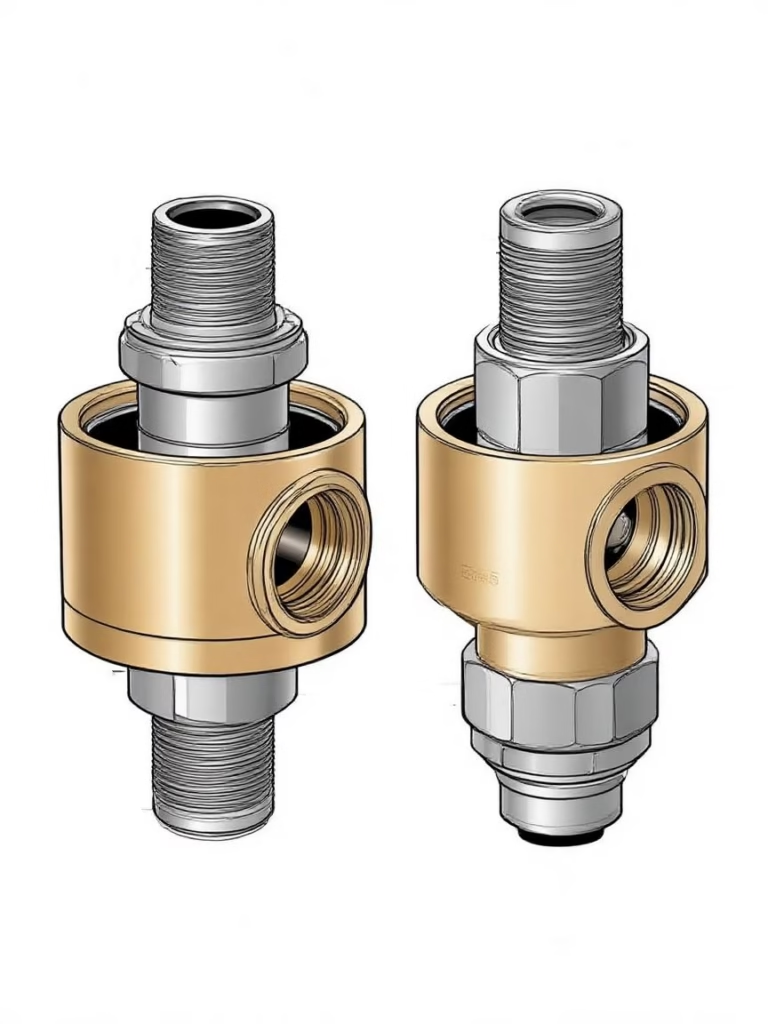

A rotary union, also known as a swivel joint or swivel union, typically serves when the primary function is to transfer fluid media, such as water, oil, steam, or compressed air. It consists of a stationary housing connected to the fluid source or supply lines and a rotating shaft attached to the moving part of the machine. Inside the union, seals and bearings ensure a leak-proof connection and smooth rotation, allowing the fluid to flow continuously without interruption as the shaft turns.

Rotary Joints

Rotary joints, on the other hand, can have a broader scope. Besides fluid transfer, they can also transmit electrical power, data signals, or a combination of different media. Some rotary joints are designed to handle multiple fluid channels simultaneously, while others are specialized for specific applications, such as high-speed or high-pressure environments. The construction of rotary joints often includes more complex internal mechanisms to accommodate the additional functionality, like electrical slip rings for power and signal transfer.

Types of Rotary Unions and Joints

The world of rotary unions and joints is diverse, offering a wide variety of types to meet the specific requirements of different industries and applications. Here are some of the most common types:

Single-Way Rotary Unions

Single-way rotary unions are the simplest form, designed for transferring a single fluid medium. They have a single inlet and outlet, and the fluid flows through a single internal channel. People commonly use these unions in applications where only one type of fluid, such as coolant or lubricant, needs to transfer to a rotating component. For example, in a metalworking lathe, a single-way rotary union can supply cutting fluid to the cutting tool to cool and lubricate it during operation.

Multi-Way Rotary Unions

As the name suggests, multi-way rotary unions can handle multiple fluid media simultaneously. They feature multiple inlet and outlet ports, each connecting to a separate internal channel. This enables the transfer of different fluids, such as water for cooling and oil for lubrication, to different parts of a rotating machine. Industries widely use multi-way rotary unions in complex industrial processes, such as injection molding machines, where they need to manage multiple fluids precisely to ensure proper operation and product quality.

High-Pressure Rotary Unions

Engineers design high-pressure rotary unions to withstand high-pressure fluid environments. They use robust materials, such as stainless steel or alloy steel, and incorporate advanced sealing technologies to prevent leakage under extreme pressure conditions. People commonly use these unions in the oil and gas industry to transfer drilling mud, hydraulic fluids, and other high-pressure substances in drilling rigs and production equipment. They are also essential in hydraulic presses and other high-pressure industrial applications.

High-Temperature Rotary Unions

For applications involving high-temperature fluids, such as steam or hot oils, high-temperature rotary unions are the go-to solution. Manufacturers make these unions from materials with high-temperature resistance, such as ceramic-coated metals or special alloys. The seals in high-temperature rotary unions are also designed to maintain their integrity and sealing performance at elevated temperatures. You can commonly find them in the paper and pulp industry, where steam is used for drying paper, and in food processing plants for processes like cooking and sterilization.

Electrical Rotary Joints

Electrical rotary joints, also known as slip rings, are for transmitting electrical power and signals between stationary and rotating parts of a machine. They consist of a set of stationary contacts (brushes) and a rotating contact surface (ring). As the ring rotates, the brushes maintain electrical contact, allowing the transfer of electricity and data. People use electrical rotary joints in a wide range of applications, including wind turbines, where they transfer power from the rotating blades to the stationary generator, and industrial robots for signal transmission between the robot arm and the control system.

Pneumatic Rotary Unions

Pneumatic rotary unions are specifically for transferring compressed air. People use them in applications where pneumatic power is necessary to operate rotating equipment, such as pneumatic tools, air-operated valves, and conveyor systems. Pneumatic rotary unions are typically lightweight and have a simple design to ensure efficient airflow and minimize pressure drops.

Working Principles of Rotary Unions and Joints

The operation of rotary unions and joints is based on a combination of mechanical and sealing principles. Here’s a closer look at how they work:

Fluid Transfer

When it comes to fluid-transfer rotary unions and joints, the key is maintaining a continuous and leak-proof connection between the stationary and rotating parts. The stationary housing connects to the fluid source, and the fluid enters the union through the inlet port. Inside the union, the fluid flows through the internal channels towards the rotating shaft. Seals, typically made of materials like rubber, fluorocarbon, or PTFE, create a tight seal between the stationary and rotating components, preventing the fluid from leaking out. The bearings support the rotating shaft, reducing friction and enabling it to rotate smoothly. As the shaft rotates, the fluid is carried along and exits the union through the outlet port, which connects to the rotating part of the machine where the fluid is needed.

Electrical and Signal Transmission

In the case of electrical rotary joints (slip rings), the principle involves maintaining electrical contact between the stationary and rotating elements. The stationary brushes, made of conductive materials like carbon or metal, are positioned to press against the rotating ring. As the ring rotates, the brushes slide along its surface, ensuring a continuous electrical connection. This enables electrical power, control signals, or data transmission from the stationary side to the rotating side of the machine. The design of the slip ring and brushes is crucial for minimizing electrical resistance, reducing wear, and ensuring reliable transmission.

Applications of Rotary Unions and Joints

Rotary unions and joints find applications in a vast array of industries, each with its unique requirements and challenges. Here are some of the major industries where these devices play a crucial role:

Manufacturing Industry

In the manufacturing sector, people use rotary unions and joints in countless machines and processes. In metalworking, they supply coolant and lubricant to cutting tools in lathes, milling machines, and grinders, improving tool life and the quality of the finished product. And in injection molding and blow molding machines, multi-way rotary unions transfer hydraulic fluids for mold movement, cooling water for temperature control, and air for part ejection. They are also essential in assembly lines, where they power pneumatic tools and transfer fluids for various operations.

Food and Beverage Industry

The food and beverage industry has strict hygiene and safety standards, and manufacturers design rotary unions and joints to meet these requirements. People use them in filling machines to transfer liquids, such as beverages, sauces, and oils while maintaining product integrity. In food processing equipment, such as mixers, homogenizers, and pasteurizers, rotary unions transfer steam, hot water, and cleaning agents for cooking, sterilization, and sanitation purposes. Using materials resistant to corrosion and easy to clean is essential in this industry to prevent contamination.

Paper and Pulp Industry

In paper mills, rotary unions and joints are involved in almost every stage of the paper-making process. They transfer steam for drying the paper, water for cooling and cleaning the machinery, and chemicals for pulp processing. High-temperature rotary unions are particularly important in the drying section, where they must withstand the high temperatures and pressures of the steam. The reliability of these components is crucial for ensuring continuous production and high-quality paper output.

Oil and Gas Industry

The oil and gas industry operates in some of the most demanding environments, and rotary unions and joints are essential for its operations. In drilling rigs, high-pressure rotary unions transfer drilling mud to the drill bit, helping to cool and lubricate the bit, remove cuttings from the wellbore, and maintain pressure control. People also use them in production facilities to transfer oil, gas, and other fluids between different parts of the equipment. Electrical rotary joints are used in subsea applications to transmit power and signals between the surface and underwater equipment.

Aerospace Industry

In the aerospace sector, people use rotary unions and joints in aircraft engines, landing gear systems, and flight control surfaces. They transfer fuel, lubricants, hydraulic fluids, and electrical signals. The components must be lightweight, reliable, and able to withstand extreme temperatures, pressures, and vibrations. For example, in jet engines, rotary unions ensure the continuous supply of fuel and lubricants to the rotating parts, while electrical rotary joints are for power and data transfer in various avionics systems.

Energy Industry

In the energy industry, rotary unions and joints are crucial for power generation. In wind turbines, electrical rotary joints transfer power from the rotating blades to the generator, enabling the conversion of mechanical energy into electrical energy. And in power plants, they transfer steam, water, and other fluids in turbines, boilers, and cooling systems. The efficiency and reliability of these components directly impact the overall performance and output of the power generation facility.

Benefits of Using Rotary Unions and Joints

Using rotary unions and joints offers several significant benefits to industrial operations:

Improved Efficiency

By enabling the seamless transfer of fluids, gases, and electrical power between stationary and rotating components, rotary unions and joints ensure that machines operate smoothly and efficiently. They eliminate the need for complex and cumbersome hoses or cables that would otherwise restrict the movement of the rotating parts. This results in reduced downtime, increased productivity, and improved overall process efficiency.

Enhanced Reliability

Manufacturers design high-quality rotary unions and joints to be durable and reliable, even in harsh operating conditions. They build them with robust materials and advanced sealing technologies to prevent leaks, wear, and failure. This reliability minimizes the risk of unexpected breakdowns, which can cause costly production interruptions and damage to equipment. Regular maintenance and properly selecting the right type of union or joint further enhance their reliability.

Cost Savings

Although rotary unions and joints may have an initial cost, they can lead to significant cost savings in the long run. Their reliability reduces the need for frequent repairs and replacements, saving on maintenance costs. Additionally, by improving the efficiency of industrial processes, they can help reduce energy consumption and waste, resulting in lower operating costs. In some cases, using rotary unions and joints can also extend the lifespan of the connected equipment, further adding to the cost savings.

Versatility

Rotary unions and joints come in a wide variety of types and configurations, making them highly versatile. You can customize them to meet the specific requirements of different applications, whether it’s handling multiple fluids, operating at high pressures or temperatures, or transmitting electrical signals. This versatility allows industries to use a single component for multiple functions, simplifying the design and operation of their machinery.

Choosing the Right Rotary Union or Joint

Selecting the appropriate rotary union or joint for a specific application is a critical decision that can impact the performance, reliability, and cost of the entire system. Here are some key factors to consider:

Fluid Type and Properties

The first and most important factor is the type of fluid or media that you will transfer. Different fluids have different chemical properties, viscosities, and temperature and pressure requirements. For example, if the fluid is corrosive, you need a union or joint made from a corrosion-resistant material, such as stainless steel or a special alloy. If the fluid is highly viscous, you may need a design with a larger internal diameter and lower fluid resistance to ensure proper flow.

Operating Conditions

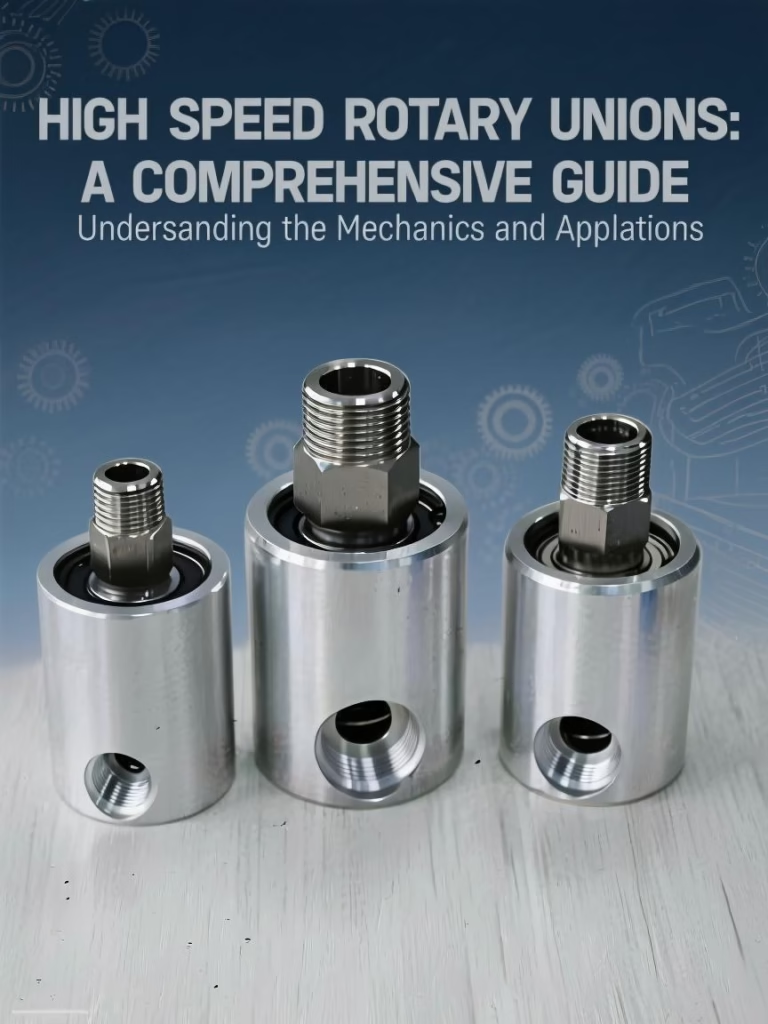

The operating conditions, including temperature, pressure, and rotational speed, play a crucial role in the selection process. Each rotary union or joint has a specified operating range for these parameters, and it’s essential to choose a component that can handle the expected conditions of the application. For high-temperature applications, you will need unions with heat-resistant materials and seals, while high-pressure applications require robustly constructed joints with reliable sealing mechanisms. Similarly, high-speed rotations may need bearings and seals that can withstand the increased centrifugal forces and friction.

Connection Type

The connection type between the rotary union or joint and the fluid supply lines or the rotating equipment is another important consideration. Common connection types include threaded connections, flanged connections, and quick-disconnect couplings. Threaded connections are simple and easy to install, but may not be suitable for high-pressure applications. Flanged connections are more secure and can handle higher pressure, but are more complex to install. Quick-disconnect couplings are convenient for applications where you need frequent disconnection and reconnection, such as in mobile equipment or for maintenance purposes.

Size and Configuration

The size and configuration of the rotary union or joint need to match the requirements of the application. Larger unions generally have a higher flow capacity but also take up more space. The configuration, such as the number of channels and the orientation of the inlet and outlet ports, should be compatible with the layout of the machine and the fluid flow paths. For unique or complex applications, you may need custom-designed unions or joints.

Manufacturer Reputation and Support

Choosing a reputable manufacturer is essential for obtaining high-quality rotary unions and joints. A reliable manufacturer will have a proven track record of producing durable and reliable products. They should also offer technical support, including assistance with product selection, installation, and maintenance. Good after-sales service, such as the availability of replacement parts and prompt response to customer inquiries, is also important for ensuring the long-term performance of the components.

Maintenance and Troubleshooting

Proper maintenance is key to ensuring the long-term performance and reliability of rotary unions and joints. Here are some maintenance tips and common troubleshooting techniques:

Regular Inspection

Regularly inspect the rotary union or joint for signs of leakage, wear, or damage. Check the seals, bearings, and connections for any abnormalities. Look for fluid stains or drips around the union, which may indicate a leak. Inspect the rotating shaft for any signs of corrosion or excessive wear. Detecting problems early can prevent more serious issues from developing.

Lubrication

If the rotary union or joint has bearings, ensure that you lubricate them properly according to the manufacturer’s recommendations. Use the recommended lubricant and follow the specified lubrication intervals. Proper lubrication helps reduce friction, wear, and heat generation, extending the life of the bearings and the overall component.

Seal Replacement

Seals are one of the most critical components of rotary unions and joints, and they will wear over time. Replace the seals as soon as they show signs of deterioration, such as cracking, hardening, or loss of elasticity. Using the correct type and size of seals is essential for maintaining a leak-proof connection.

Cleaning

Keep the rotary union or joint clean, especially in applications where the fluid being transferred may contain contaminants. Regularly clean the external surfaces to prevent the accumulation of dirt, debris, or corrosion-causing substances. In some cases, you may need to clean the internal channels to remove any blockages or deposits that could affect fluid flow.

Troubleshooting

If a problem occurs, such as leakage, abnormal noise, or reduced performance, start by identifying the possible causes. Leakage may be due to worn-out seals, damaged mating surfaces, or improper installation. Abnormal noise could indicate bearing wear, misalignment, or excessive friction. Reduced performance, such as a decrease in fluid flow or electrical transmission, may be caused by blockages, worn components, or incorrect operating conditions. Once you identify the cause, take the appropriate corrective action, such as replacing the faulty component, adjusting the alignment, or cleaning the internal channels.

Future Trends in Rotary Union and Joint Technology

As industries continue to evolve and demand more efficient, reliable, and versatile solutions, the technology behind rotary unions and joints is also advancing. Here are some future trends to watch out for:

Smart and Connected Components

Integrating sensors and IoT (Internet of Things) technology into rotary unions and joints is becoming increasingly common. Smart components can monitor parameters such as temperature, pressure, vibration, and seal integrity in real time. You can transmit this data wirelessly to a central control system, allowing for predictive maintenance, early fault detection, and optimization of the overall system performance.

Advanced Materials

Developing new materials with enhanced properties, such as improved corrosion resistance, higher temperature tolerance, and better wear resistance, will continue to drive the evolution of rotary unions and joints. Nanomaterials, composites, and advanced polymers are likely to play a significant role in creating more durable and efficient components.

Miniaturization

In some industries, such as aerospace and medical devices, there is a growing need for smaller and more compact rotary unions and joints. Advances in manufacturing techniques, such as micro-machining and 3D printing, will enable the production of miniature components without sacrificing performance or reliability.

Multi-Functionality

There is a trend towards developing rotary unions and joints that can perform multiple functions simultaneously. For example, a single component may be able to transfer multiple fluids, transmit electrical power and signals, and even provide mechanical support. This multi-functionality reduces the complexity and size of the overall system, leading to cost savings and improved efficiency.

Conclusion

Rotary unions and joints are indispensable components in modern industrial systems, enabling the seamless transfer of fluids, gases, and electrical power between stationary and rotating parts. Their versatility, reliability, and efficiency make them essential in a wide range of industries, from manufacturing and food processing to energy and aerospace. By understanding the different types, working principles, applications, and selection criteria, businesses can choose the right rotary union or joint for their specific needs, ensuring the smooth operation of their machinery and the success of their operations.

With ongoing technological advancements, the future of rotary union and joint technology looks promising, offering even more innovative solutions to meet the evolving demands of industries worldwide. Whether you’re involved in the design, operation, or maintenance of industrial equipment, a solid understanding of rotary unions and joints is essential for staying ahead.