Why Do Rotary Unions Leak? The Comprehensive Troubleshooting Guide for Engineers

Introduction: The High Cost of a Drip

In the high-stakes environment of industrial manufacturing, a small puddle of hydraulic oil or a hiss of escaping steam is never “just a leak.” It is a warning sign. For plant managers and maintenance engineers, Rotary Union Leak (also known as a rotary joint or swivel joint) represents an immediate threat to production efficiency, safety, and profitability.

While rotary unions are designed to be durable components capable of withstanding high pressures and speeds, they are not invincible. Premature failure is rarely a defect of the product itself but rather a symptom of environmental factors, installation errors, or operational stress.

As a manufacturer with years of experience in engineering fluid transfer solutions, we have analyzed thousands of failed units. The data is clear: over 90% of seal failures are preventable.

This guide goes beyond the basics. We will delve into the technical root causes of rotary union leakage, examine the physics of seal failure, and provide you with an actionable roadmap to troubleshoot issues and extend the lifespan of your machinery.

Table of Contents

1. Introduction: The High Cost of a Drip

2. Understanding the Core: How Rotary Union Seals Actually Work

3. The Top 5 Causes of Rotary Union Leak and Seal Failure

- Improper Installation & Misalignment (The #1 Culprit)

- Fluid Contamination & Poor Filtration

- Dry Running & Thermal Shock

- Operating Outside Technical Specifications

- Excessive Vibration & Machine Run-out

4. Visual Diagnostics: Reading Your Damaged Seals

5. Preventive Maintenance: How to Extend Service Life

6. Frequently Asked Questions (FAQ)

Understanding the Core: How Rotary Union Seals Actually Work

To understand why a joint leaks, you must first understand how it seals. A rotary union is a mechanical device that allows the transfer of fluid from a stationary source to a rotating part. The heart of this device is the mechanical seal.

Unlike a simple rubber O-ring that seals static parts, a mechanical seal in a rotary union is dynamic. It typically consists of two primary faces:

-

The Rotating Face: Attached to the rotor.

-

The Stationary Face: Held in the housing.

These two faces are lapped to a flatness measured in light bands (millionths of an inch). When the union is operating, a microscopic film of the fluid being transferred (hydraulic oil, water, coolant) enters the gap between these faces. This fluid film is critical; it lubricates the faces and reduces friction.

The “Leak” Reality: Technically, all mechanical seals leak a microscopic amount of fluid vapor to lubricate the faces. However, a visible leak means this delicate balance has been destroyed. The gap has opened up, or the faces have been damaged.

The Top 5 Causes of Rotary Union Leak and Seal Failure

When a customer asks, “Why is my rotary joint leaking?”, the answer almost always points to one of these five culprits.

1. Improper Installation & Misalignment (The #1 Culprit)

If we had to pick one reason for early failure, this is it. Misalignment and side loading are the silent killers of rotary unions.

The Hard Piping Mistake: Many technicians, aiming for a “clean” look, plumbed the rotary union using rigid metal piping (hard piping) directly connected to the supply lines. This is a critical error.

-

The Physics: As the machine runs, it vibrates. Thermal expansion causes parts to shift. If the rotary union is hard-piped, there is no room for movement. The rigid pipe acts as a lever, exerting a massive side load on the union’s internal bearings.

-

The Result: The bearings wear out unevenly, the shaft tilts slightly, and the seal faces are forced open on one side. The result is immediate or rapid leakage (“weeping”).

The Fix: Always use a flexible hose to connect the supply line to the rotary union. The hose should have a slight curve (not pulled tight) to absorb vibration and thermal expansion. This allows the union to “float” and center itself, maintaining perfect seal face contact.

2. Fluid Contamination & Poor Filtration

Your hydraulic rotary union is only as clean as the fluid running through it.

The Sandpaper Effect: Modern mechanical seals, often made of Silicon Carbide or Tungsten Carbide, are extremely hard. However, if your hydraulic fluid, coolant, or thermal oil contains particulates (metal chips, grit, rust, or degraded oil sludge), these particles can embed themselves between the seal faces.

-

The Damage: These particles act like sandpaper. As the union rotates at high speed, the contaminants score grooves into the polished seal faces. Once a groove cuts across the face, it creates a permanent path for fluid to escape.

The Fix:

-

Filtration: Ensure your system filtration meets the manufacturer’s ISO cleanliness code (e.g., ISO 4406 17/15/12).

-

Quality Control: If you are using recycled water or coolant, ensure it is properly filtered before entering the rotary union. A 5-micron filter is often recommended for high-speed applications.

3. Dry Running & Thermal Shock

Rotary unions are not designed to run dry (unless specifically engineered for air/vacuum). They rely on the media they transfer to lubricate and cool the seal faces.

What Happens During a Dry Run: Imagine rubbing your hands together. Now imagine doing it at 3,000 RPM. Without fluid to dissipate the heat, the friction between the seal faces generates extreme temperatures within seconds.

-

Thermal Shock: The rapid heating causes the seal materials to expand unevenly. When cold fluid is finally introduced, the thermal shock causes the ceramic or carbide faces to crack. This is often visible as heat checking—fine radial cracks on the seal face that look like a shattered windshield.

-

O-Ring Damage: The heat can also melt or harden the secondary rubber O-rings, causing them to lose elasticity and fail.

The Fix: Install flow switches or pressure sensors interlocked with the machine’s motor. Ensure the fluid supply is active before the rotation begins.

4. Operating Outside Technical Specifications

Every rotary union has a specific “PV Limit” (Pressure x Velocity). Pushing a unit beyond its design limits is a recipe for disaster.

The Danger of Over-Pressure: If a union is rated for 3,000 PSI, running it at 4,000 PSI—even momentarily—can force the seal faces apart or cause O-ring extrusion. Extrusion happens when the high pressure pushes the rubber O-ring into the tiny gap between metal parts, “nibbling” it away until it fails.

The Danger of Overspeed: Exceeding the maximum RPM generates centrifugal forces and heat that the bearings and seals cannot handle. This leads to vibration and rapid wear.

The Fix: Always consult the technical datasheet. If your application parameters have changed (e.g., you upgraded the machine speed), you must upgrade the rotary union to match. Do not assume the old part can handle the new load.

5. Excessive Vibration & Machine Run-out

Sometimes, the problem isn’t the union; it’s the machine.

Concentricity Matters: The rotary union is mounted to a machine shaft. If that shaft is bent, or if the bearings in the machine itself are worn, the shaft will wobble. This is known as run-out.

- The Effect: The rotary union tries to follow this wobbling motion. This creates a “camming” action that forces the internal seals to open and close rapidly with every revolution. Eventually, the springs or seals fatigue and fail.

The Fix: Before installing a new rotary union, use a dial indicator to measure the run-out of the machine interface. Typically, this should be less than 0.002 inches (0.05 mm). If the machine has high vibration, consider a specialized rotary union designed with wider bearing spacing to handle the instability.

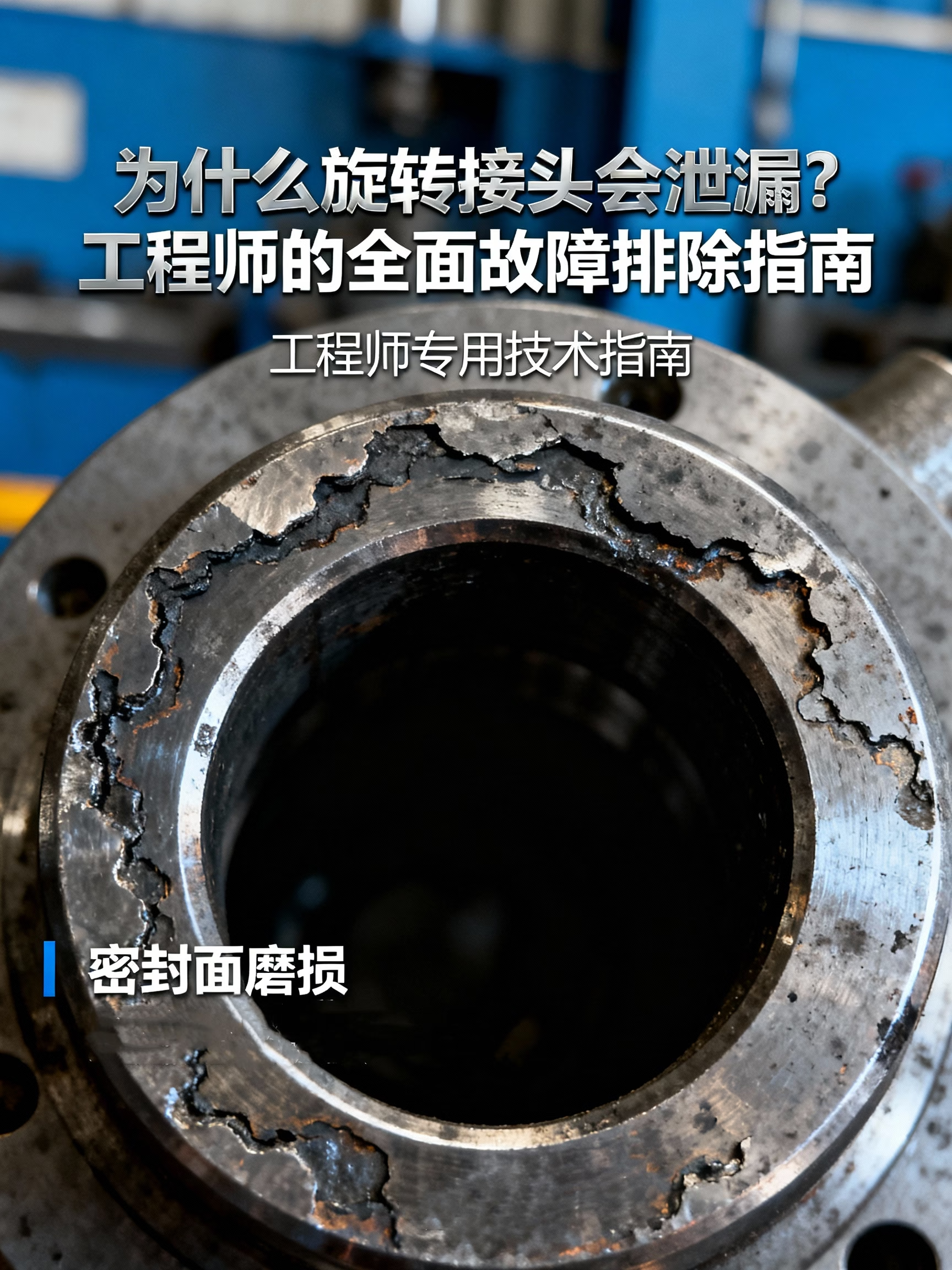

Visual Diagnostics: Reading Your Damaged Seals

When you remove a failed rotary joint, don’t just throw it away. Inspect the internal components. The damage tells a story.

Visual Symptom Probable Cause Corrective Action

Heat Checking (Fine radial cracks on seal face) Dry Running or insufficient cooling. Verify flow is present before rotation.Check for trapped air.

Heavy Scoring (Deep grooves on seal face) Contamination in the fluid. Improve filtration quality. Flush the system.

Uneven Wear (One side worn more than the other) Misalignment or Side Loading. Switch from hard pipe to flexible hose. Check concentricity.

O-Ring Extrusion (Rubber looks "chewed" or peeled)" Excessive Pressure or pressure spikes. Install accumulators; verify max pressure rating.

Carbon Blistering (Bubbles on seal face) Chemical Incompatibility or overheating oil. Check fluid compatibility with seal materials.

Preventive Maintenance: How to Extend Service Life

You don’t have to wait for a leak to act. Implementing a preventative maintenance plan can double the life of your hydraulic rotary unions.

-

Daily Visual Checks: Look for “weeping” at the drain holes. A small drop occasionally might be normal, but continuous dripping is a failure.

-

Monitor Vibration: If a union that used to be quiet starts buzzing or vibrating, the bearings are likely nearing the end of their life. Replace it before it seizes.

-

Lubrication (For Bearing-Supported Models): Some rotary unions have grease fittings for the bearings. Follow the manufacturer’s schedule. Note: Do not over-grease, as this can damage seals.

-

Hose Inspection: Ensure the flexible hoses connecting the union are not twisted, kinked, or pulling on the union.

Frequently Asked Questions (FAQ)

Q: Can I repair a Rotary Union Leak myself?

A: Yes, many industrial rotary unions are designed to be field-repairable using a repair kit (which typically includes new seals, O-rings, and bearings). However, if the metal housing or shaft is scored or damaged, a simple seal replacement won’t work. In that case, a full unit replacement is the safer option.

Q: Why does my rotary union leak immediately after installation?

A: Immediate leakage is almost always due to an installation error. Did you use a hammer to tap it into place? (This cracks the carbon seal). Did you use hard piping instead of a flexible hose? Did you run it dry for “just a second” to test it? Any of these can destroy the seal instantly.

Q: How long should a hydraulic rotary union last?

A: This depends heavily on the application. In clean, moderate-pressure environments, a high-quality union can last for years. In high-speed, high-pressure, or dirty environments, the lifespan might be measured in months. Regular maintenance and proper specification are key to maximizing longevity.

Q: Can I use the same rotary union for water and hydraulic oil?

A: Generally, no. Water and oil have different viscosities and lubricating properties. A seal face material designed for oil (like steel-on-bronze) might wear out quickly in water. Always specify your media when ordering so the manufacturer can select the correct seal face combination (e.g., Silicon Carbide vs. Silicon Carbide for water).

Conclusion: Stop the Leaks, Boost the Efficiency

A Rotary Union Leak is a signal that your system is under stress. By understanding the root causes—whether it’s misalignment, contamination, or dry running—you can stop replacing parts blindly and start solving the actual problem.

At Dann, we don’t just sell parts; we provide solutions. Our H-Series and Stainless Steel Rotary Unions are engineered with advanced sealing technology to resist these common failure modes.

Are you tired of frequent seal failures? Contact our engineering team today for a free consultation. We can help you identify the root cause of your leakage and recommend a rotary union alternative that is built to last.