What Factors Affect Hydraulic Rotary Joint Price?

Rotary joints are critical components in machinery and equipment that require continuous rotational movement while transferring fluids, gases, or electrical signals. Whether in manufacturing, robotics, aerospace, or energy sectors, the hydraulic rotary joint price can significantly impact project budgets and operational efficiency. Understanding the factors that influence hydraulic rotary joint price is essential for buyers, engineers, and procurement teams to make informed decisions. This article delves into the key elements driving cost variations, including material selection, design complexity, market dynamics, and more. Let’s explore the factors that affect the hydraulic rotary joint price.

1. Material Selection: The Foundation of Cost

The choice of materials directly affects durability, performance, and price. Common materials include:

Metals:

High-quality metals like stainless steel dominate rotary joint construction because they resist corrosion effectively. Manufacturers commonly choose stainless steel, especially grades such as 304 and 316, to ensure the joints endure harsh environments with moisture, chemicals, or high temperatures. For example, engineers in the food and beverage industry prefer stainless-steel rotary joints since they clean easily and prevent product contamination. When facing highly corrosive chemical processes, designers often select specialized alloys like Hastelloy for their superior corrosion resistance. However, these alloys raise the overall cost because they require complex manufacturing and expensive raw materials.

Manufacturers also integrate plastics or polymers into some rotary joints for specific components. Engineers often use PTFE for seals due to its low friction and strong chemical resistance. Designers use nylon or polycarbonate in non-critical parts to cut costs and reduce weight.

Ceramics:

Ceramic materials are used in high-performance rotary joints, particularly in applications where extreme temperatures, high wear, or electrical insulation are needed. Ceramic components can offer superior hardness and wear resistance compared to metals. Engineers use ceramic bearings in high-speed rotary joints to reduce friction, though they increase cost.

Impact on Price

The choice of material has a direct impact on the price of a rotary joint. High-quality materials that offer better performance, durability, and resistance to harsh conditions are more expensive. A rotary joint made entirely of stainless steel or a specialized alloy will be costlier than one made with a combination of standard metals and plastics. The cost of raw materials, as well as the difficulty in processing them, contributes to the overall price difference. For example, manufacturing a rotary joint with Hastelloy requires specialized equipment and skilled labor due to the alloy’s hardness and unique properties, driving up the cost.

2. Design Complexity and Engineering

High-Pressure and High-Temperature Requirements

Engineering for High-Pressure Applications:

Rotary joints designed to handle high pressures need to be engineered with stronger materials and more robust sealing mechanisms. In industries such as oil and gas, where rotary joints are used in drilling equipment and pipelines, they may need to withstand pressures of several thousand pounds per square inch (psi). These high-pressure rotary joints often have thicker walls, reinforced flanges, and advanced sealing systems to prevent leaks. For example, in a hydraulic rotary joint used in a high-pressure hydraulic system for heavy-duty machinery, the joint must be able to handle the high-pressure fluid without failure.

Handling Extreme Temperatures:

Similarly, rotary joints used in high-temperature applications, such as those in the aerospace industry for jet engines or in industrial furnaces, require materials that can maintain their integrity at elevated temperatures. They may be made of heat-resistant alloys or ceramics. In a steam rotary joint used in a power plant, the joint must be able to handle high-temperature steam, often at temperatures above 200°C. On the other hand, in cryogenic applications, such as in the liquefied natural gas (LNG) industry, rotary joints need to perform at extremely low temperatures, which also requires specialized materials and design considerations.

Cost Implications

Rotary joints with higher pressure and temperature ratings are more expensive due to several factors. First, the materials used to withstand these extreme conditions are costlier. Second, the design and manufacturing processes are more complex, requiring advanced engineering techniques and quality control measures. The testing procedures for high-pressure and high-temperature rotary joints are also more rigorous, adding to the overall cost. For example, a rotary joint that can handle 5000 psi of pressure will be significantly more expensive than one designed for a standard 100 – 200 psi application in a typical industrial setting.

Design Complexity

Number of Passages (Single vs. Multi-Pass)

Single-Passage Rotary Joints:

Single-passage rotary joints are the simplest in design. They are used when only one fluid, gas, or signal needs to be transferred between the stationary and rotating parts. These joints are commonly found in applications such as small-scale packaging machinery, where a single coolant line is required to cool a rotating component. The manufacturing process for single-passage rotary joints is relatively straightforward, and they are generally more affordable.

Multi-Passage Rotary Joints:

Multi-passage rotary joints, on the other hand, are designed to transfer multiple fluids, gases, or signals simultaneously. For example, in a printing press, a multi-passage rotary joint may be used to transfer ink, water (for dampening), and compressed air for pneumatic actuators all at the same time. These joints require a more complex internal design to ensure that the different media do not mix and that each passage functions properly. The manufacturing process involves precise machining and assembly to create separate channels for each medium.

Other Design-Related Factors

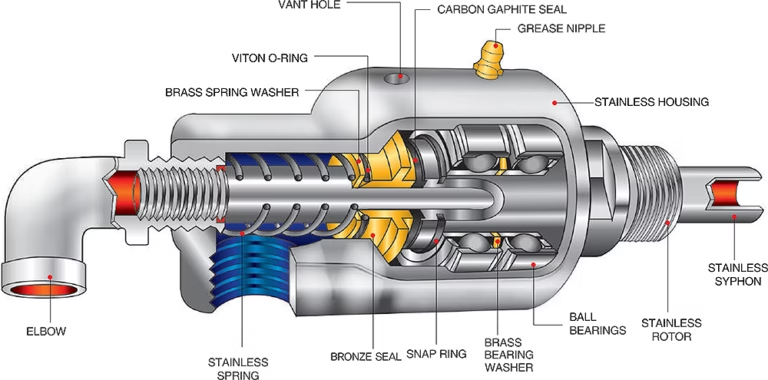

Sealing Mechanisms:

The design of the sealing mechanism in a rotary joint also affects its complexity and price. Advanced sealing technologies, such as mechanical face seals or lip seals with special coatings, are used to prevent leaks and ensure a long-lasting, reliable connection. Mechanical face seals, which consist of two flat surfaces in contact with each other (one stationary and one rotating), provide a high-performance sealing solution but are more complex and expensive to manufacture. Lip seals, which use elastomeric materials to create a seal, are less expensive but may not be suitable for high-pressure or high-temperature applications.

Mounting and Connection Types:

The way a rotary joint mounts and connects to other components can also add to its design complexity. Some rotary joints require specialized flanges, couplings, or threaded connections to ensure a secure and leak-free installation. For example, in a high-vibration environment, a rotary joint may need a vibration-damping mounting system, which adds to the overall design and cost.

Pricing Due to Complexity

As the design of a rotary joint becomes more complex, the price increases. Multi-passage rotary joints are generally more expensive than single-passage ones due to the additional engineering and manufacturing processes involved. Advanced sealing mechanisms and specialized mounting types also contribute to a higher price tag. A rotary joint with a complex multi-passage design and high-performance sealing technology can cost several times more than a basic single-passage joint with standard sealing.

3. Manufacturing Process and Quality Control

Customization Requirements

Tailoring for Specific Applications

Unique Operational Environments:

Some industries have unique operational environments that require custom-designed rotary joints. For example, in the mining industry, where rotary joints may be exposed to abrasive dust, high humidity, and heavy vibrations, a standard rotary joint may not be suitable. A custom rotary joint can be designed with additional dust-proof seals, reinforced housing to withstand vibrations, and materials that can resist corrosion from the harsh mining environment.

Specialized Machinery:

In specialized machinery, such as custom-built medical equipment or high-precision robotic systems, the rotary joints need to meet very specific requirements. In a robotic surgical arm, the rotary joint must be extremely precise, have low friction, and be able to transfer multiple signals (electrical and optical) while maintaining a high degree of sterility. Custom rotary joints for such applications are designed from the ground up to meet these exacting standards.

Cost of Customization

Customization of rotary joints comes at a premium price. The design process for a custom rotary joint involves close collaboration between the manufacturer and the customer to understand the specific requirements. This often requires additional engineering time and resources. The manufacturing process may also need to be adjusted to produce a one-off or low-volume product, which can be less efficient and more costly. For example, if a customer needs a rotary joint with non-standard dimensions or a unique combination of features, the manufacturer may need to create custom molds, fixtures, or tooling, all of which add to the overall cost.

4. Market Dynamics and Supply Chain

Market Demand

Industry-Specific Demand

Automotive Industry:

The automotive industry has a high demand for rotary joints in various applications such as engine cooling systems, power steering systems, and vehicle suspension systems. In an engine cooling system, a rotary joint may be used to transfer coolant between the stationary engine block and the rotating water pump. As the automotive industry continues to grow, especially with the increasing production of electric vehicles that also require rotary joints for battery cooling and other functions, the demand for rotary joints in this sector is on the rise.

Aerospace Industry:

Engineers in the aerospace industry use rotary joints in aircraft engines, landing gear systems, and avionics equipment. For example, in an aircraft engine, they install rotary joints to transfer fuel, lubricants, and hydraulic fluids between stationary and rotating components. The industry’s emphasis on safety and performance in flight drives engineers to demand high-quality, reliable rotary joints. Any failure in an aerospace rotary joint could have catastrophic consequences.

Energy Sector:

The energy sector, including oil and gas, wind power, and solar power, also requires a large number of rotary joints. Oil and gas operators use rotary joints in drilling rigs to transfer drilling fluids efficiently. In wind turbines, engineers install rotary joints to transfer electrical power and control signals between the stationary tower and the rotating blades. As the world shifts toward renewable energy sources, energy companies increasingly adopt rotary joints in wind and solar power systems, driving significant growth in demand.

Impact on Pricing

When the demand for rotary joints in a particular industry or across multiple industries is high, the price tends to increase. This is due to several factors. First, manufacturers may face capacity constraints, and as a result, they may increase prices to manage the demand. Second, high demand can lead to shortages of raw materials, which in turn drives up the cost of production and ultimately the price of the rotary joints. For example, during a boom in the oil and gas industry, the demand for high-pressure rotary joints used in drilling operations may increase, causing the prices of these joints to rise.

Volume of Purchase

Economies of Scale

Bulk Purchasing Advantages:

When businesses purchase rotary joints in large quantities, they can benefit from economies of scale. Manufacturers are often able to offer lower unit prices for bulk orders. This is because the fixed costs associated with production, such as setting up the manufacturing equipment, designing the product, and quality control, can be spread over a larger number of units. For example, if a manufacturer has a fixed cost of $10,000 for setting up the production line for a particular type of rotary joint, and they produce 100 units, the fixed cost per unit is $100. However, if they produce 1000 units, the fixed cost per unit drops to $10.

Lower Production Costs per Unit:

In addition to spreading fixed costs, bulk production can also lead to lower variable costs per unit. Suppliers may offer discounts on raw materials when purchased in large quantities. Also, the manufacturing process may become more efficient with higher production volumes, reducing labor costs per unit. For instance, a manufacturer may be able to negotiate a 10% discount on stainless-steel raw materials when purchasing a large quantity for a bulk order of rotary joints.

Pricing for Small Orders

On the other hand, small orders of rotary joints typically come with higher per-unit costs. The manufacturer may not be able to achieve the same level of cost savings as with large orders. The fixed costs are over a smaller number of units, and there may be less room for negotiating better prices for raw materials. For example, a small-scale business that needs only a few rotary joints for a prototype or a low-volume production run may have to pay a significantly higher price per unit compared to a large-scale manufacturer ordering hundreds of the same joints.

5. Brand and Reputation

Trust and Reliability

Quality Assurance by Reputable Brands:

Established manufacturers with a good brand reputation are often associated with high-quality products. These brands have built their reputation over time by consistently delivering reliable rotary joints. They invest in research and development to improve their products, use high-quality materials, and follow strict manufacturing and quality control processes. For example, a well-known brand in the rotary joint market may have in-house testing facilities to ensure that every product meets or exceeds industry standards.

Warranties and After-Sales Service:

Reputable brands also tend to offer better warranties and after-sales service. They stand behind their products and are more likely to provide support in case of any issues. A brand may offer a one-year or even a multi-year warranty on their rotary joints, which gives customers peace of mind. In addition, they may have a dedicated customer service team to handle any inquiries or problems related to the product.

Premium Pricing

Customers are often willing to pay a premium for trusted brands. The perceived value of a reliable product with a good warranty and after-sales service justifies the higher price. For example, a brand-name rotary joint may cost 20 – 30% more than a similar-looking product from an unknown or less-established manufacturer. However, businesses may choose the brand-name product to avoid potential risks associated with lower-quality alternatives, such as premature failure, production downtime, and costly repairs.

Maintenance Costs

Anticipated Maintenance Requirements

Frequency of Maintenance:

Manufacturers design some rotary joints to require less frequent maintenance. For example, they extend service life and reduce servicing needs by using advanced sealing technologies and high-quality materials. In a continuous-production manufacturing plant, a low – maintenance rotary joint can be a significant advantage as it reduces the need for production stoppages for maintenance. On the other hand, rotary joints with basic designs and lower-quality components may require more frequent maintenance, such as regular seal replacements or lubrication.

Ease of Maintenance:

The ease of maintenance is another factor. Engineers design rotary joints with simple structures to reduce maintenance time and cost. Modular rotary joints let technicians quickly replace parts without disassembling the entire unit. This can save time and labor costs during maintenance.

Impact on Initial Pricing

Rotary joints that are expected to have lower maintenance costs may have a higher upfront cost. Manufacturers take into account the long-term cost of ownership when pricing their products. Customers often pay more for rotary joints that reduce maintenance over their lifespan. Manufacturers charge more for durable rotary joints that last 10 years with minimal maintenance.

Industry-Specific Regulations

Compliance Costs: Meeting industry standards (e.g., ATEX for hazardous environments, FDA for food-grade applications) adds testing and documentation expenses.

Environmental Regulations: RoHS compliance for electronics or REACH regulations for chemicals may influence material choices and costs.

After-Sales Support and Service

Maintenance and Repair: Availability of spare parts, field service, or refurbishment programs affects long-term costs.

Training and Documentation: Comprehensive user manuals, installation guides, or training sessions add value.

Technological Advancements

New Sealing Mechanisms

Improved Performance and Efficiency:

Technological advancements in sealing mechanisms have led to the development of more efficient and reliable seals for rotary joints. For example, the development of self-adjusting seals that can adapt to changes in pressure, temperature, and shaft misalignment has improved the performance of rotary joints. These new seals can reduce leakage, extend the service life of the joint, and improve overall efficiency.

Cost of Implementing New Technologies:

However, the implementation of these new sealing technologies often comes at a cost. The research and development required to create these advanced seals, as well as the cost of manufacturing them, can increase the price of the rotary joints. For example, a rotary joint with a newly developed self-adjusting seal may be 15 – 20% more expensive than a similar joint with a traditional seal.

Enhanced Performance Features

Incorporation of Smart Features:

Another area of technological advancement is the incorporation of smart features in rotary joints. Some modern rotary joints with sensors that can monitor parameters such as temperature, pressure, and vibration. This data can be used for predictive maintenance, allowing operators to detect potential problems before they cause a failure. For example, a rotary joint in a large industrial machine can send real-time data to a control system, enabling proactive maintenance and reducing unplanned downtime.

Conclusion

The hydraulic rotary joint price is a multifaceted equation involving material science, engineering, economics, and industry-specific demands. By understanding these factors, buyers can prioritize requirements, negotiate effectively, and balance cost with performance. Whether optimizing for a low-cost standard joint or investing in a high-precision custom solution, awareness of these variables ensures smarter procurement decisions.