Does rotary union has bearing in it?

Does a Rotary Union Have a Bearing in It? A Deep Dive

In the realm of industrial machinery, rotary unions (also commonly known as rotary joints) are pivotal components. Their function is to enable the transfer of fluids, such as water, steam, oil, or gases, between stationary and rotating parts of equipment. A common question among engineers and maintenance professionals is: Does a rotary union have a bearing on it? The short answer is yes, most rotary unions incorporate bearings to ensure smooth rotation, reduce friction, and support mechanical loads. This article explores the role of bearings in rotary unions, their types, applications, and maintenance considerations.

The Basics of Rotary Unions

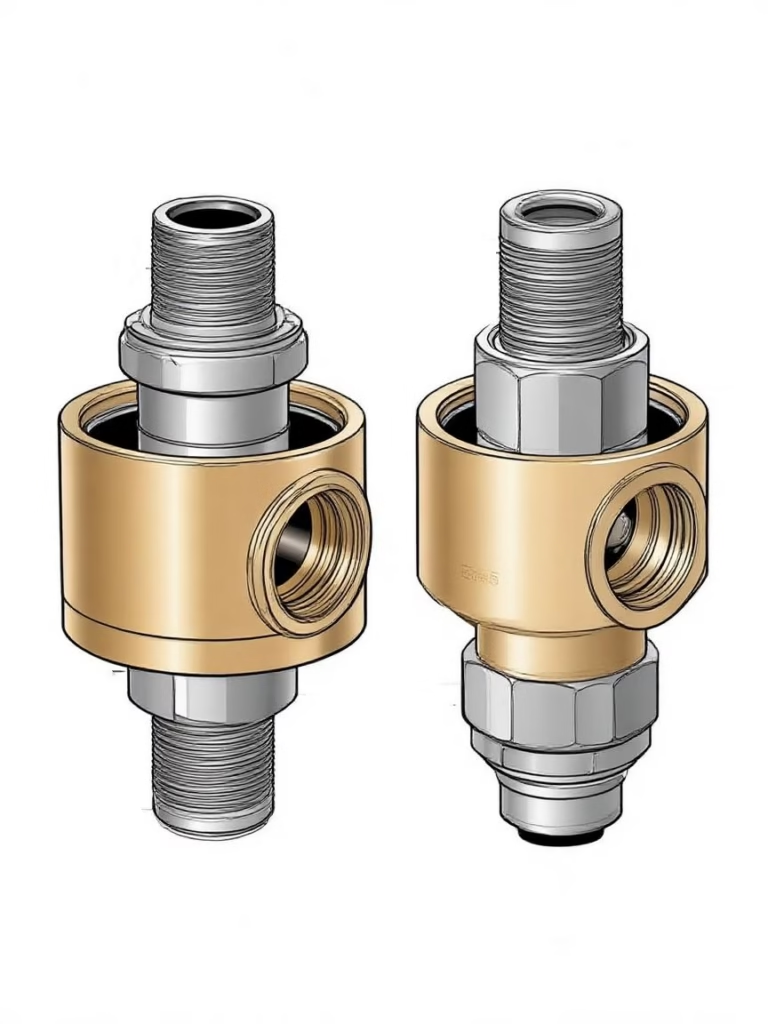

Rotary unions, also known as rotary joints or swivel joints, are critical components in industrial machinery for transferring fluids (e.g., water, oil, air) between stationary and rotating parts. It is a mechanical device that serves as a connection point for a stationary fluid source and a rotating piece of machinery. It allows for the continuous and leak-free transfer of media while accommodating the rotational movement. The basic structure of a rotary union typically consists of a stationary housing and a rotating element, often a shaft or spindle.

The stationary housing is responsible for providing a stable connection to the fluid supply lines. It contains ports through which the fluids enter and exit the union. On the other hand, the rotating element is integrated with the rotating part of the equipment, such as a drum in a printing press or a spindle in a textile machine.

The Role of Bearings in Rotary Unions

Types of Bearings Used

1. Ball Bearings

Ball bearings are one of the most commonly used types of bearings in rotary unions. They consist of a set of spherical balls that are held in place by a cage. The balls roll between two rings, known as the inner and outer races. In a rotary union, ball bearings are often used to support the rotating shaft. Their design allows for low-friction rotation, which is crucial for smooth operation. For example, in a low-pressure, high-speed application such as a small-scale food packaging machine, ball bearings can efficiently handle the rotational forces while minimizing energy consumption.

2.Roller Bearings

Roller bearings, as the name implies, use cylindrical or tapered rollers instead of balls. Cylindrical roller bearings are suitable for applications where there is a high radial load. In a rotary union used in a large-scale industrial dryer, where the rotating drum is heavy and subject to significant radial forces due to the weight of the material being dried, cylindrical roller bearings can provide the necessary support. Tapered roller bearings, on the other hand, can handle both radial and axial loads. They are often used in applications where the rotary union is exposed to complex forces, such as in some types of hydraulic rotary unions.

3.Thrust Bearings

Thrust bearings are designed to handle axial loads, that is, forces acting parallel to the axis of rotation. In a rotary union, when there is a significant axial force, such as in a centrifugal pump where the impeller creates an axial thrust, thrust bearings are employed. They help to keep the rotating shaft in proper alignment and prevent axial movement that could lead to misalignment and leakage in the rotary union.

Why Bearings are Essential in Rotary Unions

Reducing Friction

Friction is the enemy of efficient operation in any mechanical system. In a rotary union, the continuous rotation of the shaft against the stationary housing would cause excessive wear and tear without the presence of bearings. Bearings reduce this friction by providing a smooth rolling or sliding surface. This not only extends the lifespan of the rotary union but also improves the overall efficiency of the equipment. For instance, in a steam-powered rotary union used in a power generation plant, reduced friction means less energy is wasted in overcoming the resistance between the rotating and stationary parts, resulting in higher energy efficiency.

Friction Reduction: Bearings minimize wear between rotating and stationary parts, extending the union’s lifespan. The 600 series rotary union by Duff-Norton Europe employs ball bearings for low-torque operation even at 1,500 RPM.

Supporting the Rotating Shaft

The rotating shaft in a rotary union needs to be properly supported to maintain its alignment and ensure smooth rotation. Bearings act as supports, holding the shaft in place and allowing it to rotate freely. Without bearings, the shaft could wobble or become misaligned, leading to leaks in the fluid transfer system. In a printing press rotary union, where precise alignment is crucial for consistent printing quality, bearings play a vital role in keeping the shaft stable during operation.

Alignment Accuracy: Precision bearings maintain alignment, critical for applications like machine tools or wind turbines. The ML01R040F hydraulic rotary union uses bearing-supported clearance seals for gearbox lubrication in wind turbines.

Managing Loads

Rotary unions are often subjected to various types of loads, including radial loads (forces acting perpendicular to the axis of rotation) and axial loads (forces acting parallel to the axis of rotation). Bearings are designed to handle these loads effectively. Different types of bearings are selected based on the specific load requirements of the application. For example, in a heavy-duty industrial mixer with a rotary union, the bearings need to be able to withstand both the radial load from the weight of the mixing blades and the axial load generated by the mixing action.

Bearings handle axial and radial loads generated during rotation, ensuring structural stability. For example, the RX rotary union by Kadant Johnson uses deep-groove ball bearings or optional tapered roller bearings to support the rotor under high thrust loads.

Rotary Unions Without Bearings

While bearings are a common feature in most rotary unions, there are some types of rotary unions that do not rely on traditional bearings for their operation.

Sealed – Lip or Mechanical Seal – Only Rotary Unions

1.Sealed – Lip Rotary Unions

Sealed – lip rotary unions use a flexible lip seal to prevent fluid leakage. In some simple applications, such as in small-scale hobbyist machinery where the rotational speed is low and the loads are minimal, a sealed-lip rotary union can operate without bearings. The lip seal itself provides a certain degree of support to the rotating shaft, allowing it to rotate within the stationary housing. However, the lack of bearings means that these types of rotary unions are limited in terms of the loads they can handle and the rotational speeds they can achieve.

2.Mechanical Seal – Only Rotary Unions

Mechanical seal – only rotary unions rely on a mechanical seal arrangement to seal the fluid connection between the stationary and rotating parts. Similar to sealed-lip rotary unions, in some low-load, low-speed applications, they can function without bearings. The mechanical seal components, which typically consist of a stationary and a rotating face, work together to create a seal. But again, their performance is restricted compared to rotary unions equipped with bearings.

Applications of Bearing – less Rotary Unions

1.Low-Load, Low-Speed Applications

Bearing-less rotary unions find their niche in applications where the requirements are not too demanding. For example, in a small-scale laboratory centrifuge where the sample being spun is lightweight and the rotational speed is relatively low, a sealed-lip or mechanical-seal-only rotary union may be sufficient. These applications do not require the high – load-handling capabilities and precise alignment provided by bearings.

2.Cost-Sensitive Applications

In some cases, cost is a major factor. Bearing-less rotary unions are generally less expensive to manufacture and maintain compared to those with bearings. In applications where budget constraints are tight, such as in some consumer-grade small appliances that use a simple rotary union for fluid transfer, bearing-less designs may be preferred.

Factors Affecting the Use of Bearings in Rotary Unions

Operating Conditions

1.Temperature

The operating temperature of a rotary union can have a significant impact on the choice of bearings. In high-temperature applications, such as in a steam-heated rotary union in a paper mill where temperatures can reach several hundred degrees Celsius, special high-temperature-resistant bearings are required. These bearings are made from materials that can maintain their mechanical properties at elevated temperatures. For example, bearings made from ceramic materials or high-nickel alloys are often used in such applications.

2.Pressure

The pressure of the fluid being transferred through the rotary union also influences the bearing selection. In high-pressure applications, bearings need to be able to withstand the additional forces exerted by the pressurized fluid. For instance, in a hydraulic rotary union used in a construction excavator, where the hydraulic fluid is under high pressure, heavy-duty bearings with robust designs are necessary to ensure reliable operation.

3.Rotational Speed

The rotational speed of the shaft in a rotary union is another critical factor. High-speed applications require bearings that can handle the centrifugal forces generated by the rapid rotation. Ball bearings with low-friction cages and precise manufacturing tolerances are often used in high-speed rotary unions, such as those in a high-speed printing press where the cylinders may rotate at thousands of revolutions per minute.

Fluid Type

1.Corrosive Fluids

When the fluid being transferred through the rotary union is corrosive, such as in a chemical processing plant where acids or alkalis are used, the bearings need to be made from corrosion-resistant materials. Stainless steel bearings or bearings with special coatings can be used in such applications. For example, in a rotary union used to transfer sulfuric acid in a battery manufacturing facility, the bearings must be able to resist the corrosive effects of the acid to prevent premature failure.

2.Viscous Fluids

Viscous fluids, like thick oils or syrups, can also affect the performance of bearings in a rotary union. In such cases, bearings with larger clearances may be required to allow the viscous fluid to flow smoothly around the bearing elements. Additionally, the lubrication system for the bearings may need to be adjusted to ensure proper lubrication in the presence of the viscous fluid.

Load Requirements

1.Radial Loads

As mentioned earlier, the magnitude of the radial loads acting on the rotary union determines the type and size of the bearings. In applications with high radial loads, such as in a large-diameter rotary union used in a cement kiln, heavy-duty cylindrical roller bearings are typically employed to provide the necessary support.

2.Axial Loads

For applications where there are significant axial loads, thrust bearings or a combination of thrust and radial bearings are used. In a marine propeller shaft rotary union, where there are both axial and radial loads due to the forces exerted by the water on the propeller, a suitable bearing arrangement is designed to handle these complex loads.

Applications of Bearings in Rotary Unions

Bearings enable rotary unions to perform in diverse industries:

Steel Industry

High-load tapered roller bearings in the RX® handle thermal oil at 260°C for rolling mills.

Wind Energy

The ML01R040F uses flange-mounted bearings for gearbox lubrication under 100 RPM and 100 bar pressure.

Pneumatics

The RU008 air union’s ball bearings support 4,000 RPM operation in clutches and vacuum systems.

How to Choose a Bearing-Equipped Rotary Union

Consider these factors:

Speed Requirements

Ball bearings for >3,000 RPM (e.g., compressed air rotary union 1129at 30,000 RPM).

Pressure Ratings

Tapered roller bearings for high-pressure systems (up to 1,450 psi in the 1200 SR2 water union).

Environmental Conditions

Stainless steel bearings for corrosive environments (e.g., food processing).

Maintenance and Troubleshooting of Rotary Union Bearings

Regular Inspection

Regular inspection of the bearings in a rotary union is essential to ensure their proper functioning. This includes checking for signs of wear, such as pitting or scoring on the bearing surfaces, and looking for any signs of leakage around the bearing area. Visual inspection can be complemented by using vibration analysis tools. Excessive vibration in a rotary union may indicate bearing problems, such as misalignment or damaged bearing elements.

Lubrication

Proper lubrication is crucial for the longevity of rotary union bearings. The type of lubricant used depends on the operating conditions, such as temperature, speed, and the type of fluid being transferred. In high-temperature applications, heat-resistant lubricants are required. Lubrication intervals should be strictly followed according to the manufacturer’s recommendations. Failure to lubricate the bearings properly can lead to increased friction, overheating, and premature bearing failure.

Bearing Replacement

When bearings in a rotary union show signs of severe wear or damage, they need to be replaced. The replacement process should be carried out carefully, following the manufacturer’s instructions. It is important to ensure that the new bearings are of the correct type, size, and quality. After replacement, the rotary union should be tested to ensure proper operation.

Conclusion

Bearings are indispensable in rotary unions, enabling efficient fluid transfer across industries. From ball bearings in high-speed pneumatics to tapered rollers in heavy-duty steel mills, their role in reducing friction and supporting loads cannot be overstated. By selecting the right bearing type and adhering to maintenance best practices, industries can maximize operational efficiency and equipment lifespan.

For further details on specific models or technical specifications, u can contact us directly.