The Ultimate Guide to High Speed Rotary Joint Suppliers

In the ever-evolving landscape of industrial machinery, the demand for high speed rotary joint and their supplier has become increasingly prevalent. From manufacturing plants to advanced technological equipment, achieving rotary unions for high-speed applications is often the key to enhanced productivity and efficiency.

At the heart of many high-speed systems lies a crucial component: the rotary union. In this blog post, we will explore everything you need to know about rotary unions for high-speed applications, from their design and functionality to their applications, benefits, and selection criteria.

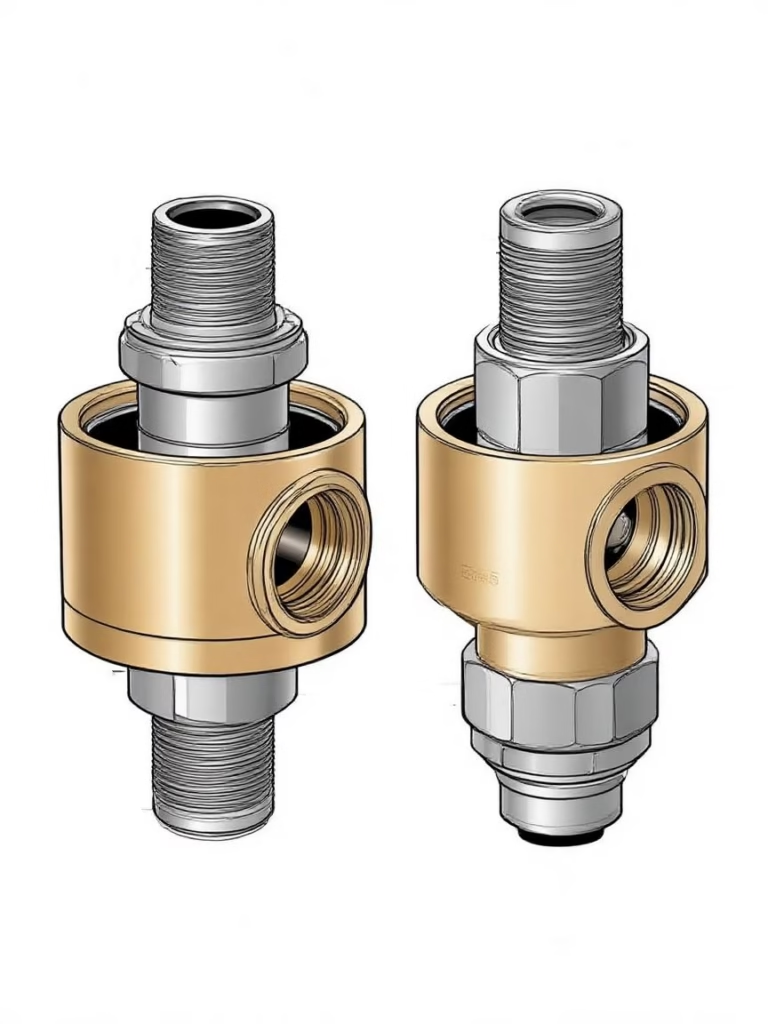

Understanding Rotary Unions

Before delving into high-speed applications, it’s essential to have a clear understanding of what rotary unions are. A rotary union is a mechanical device that facilitates the transfer of fluids, such as water, oil, steam, or air, between a stationary source and a rotating piece of equipment. This transfer occurs without interrupting the rotation of the equipment, making it an indispensable part of many industrial processes.

Rotary unions come in various types and configurations, each designed to meet specific application requirements. They typically consist of a stationary housing and a rotating shaft, along with seals and bearings that ensure a tight and smooth connection between the two components. The seals prevent fluid leakage, while the bearings support the rotating shaft and reduce friction, allowing for efficient rotation.

The specialty

High speed rotary joint is a specialized subset which engineered to withstand the unique challenges associated with rapid rotation. When equipment operates at high speeds, several factors come into play that ordinary rotary unions may not be able to handle effectively.

High-Speed – Induced Forces

At high rotational speeds, centrifugal forces and vibrations become significant concerns. Centrifugal force acts outward on the rotating components of the union, putting stress on the seals, bearings, and housing. If not properly designed to counteract these forces, the union can experience premature wear, leakage, or even catastrophic failure. Vibrations, on the other hand, can disrupt the smooth operation of the union and cause damage to its internal components over time. High-speed rotary unions incorporate features such as balanced designs and precision-engineered components to minimize the impact of these forces.

Heat Generation

Another challenge in high-speed applications is heat generation. Friction between the rotating and stationary parts of the union, as well as the internal fluid flow, can generate a substantial amount of heat. Excessive heat can degrade the performance of seals and bearings, reduce the lifespan of the union, and potentially cause fluid degradation or vaporization. To address this, high-speed rotary unions often use materials with high thermal conductivity and employ cooling mechanisms, such as internal channels for coolant flow, to dissipate heat effectively.

Sealing Requirements

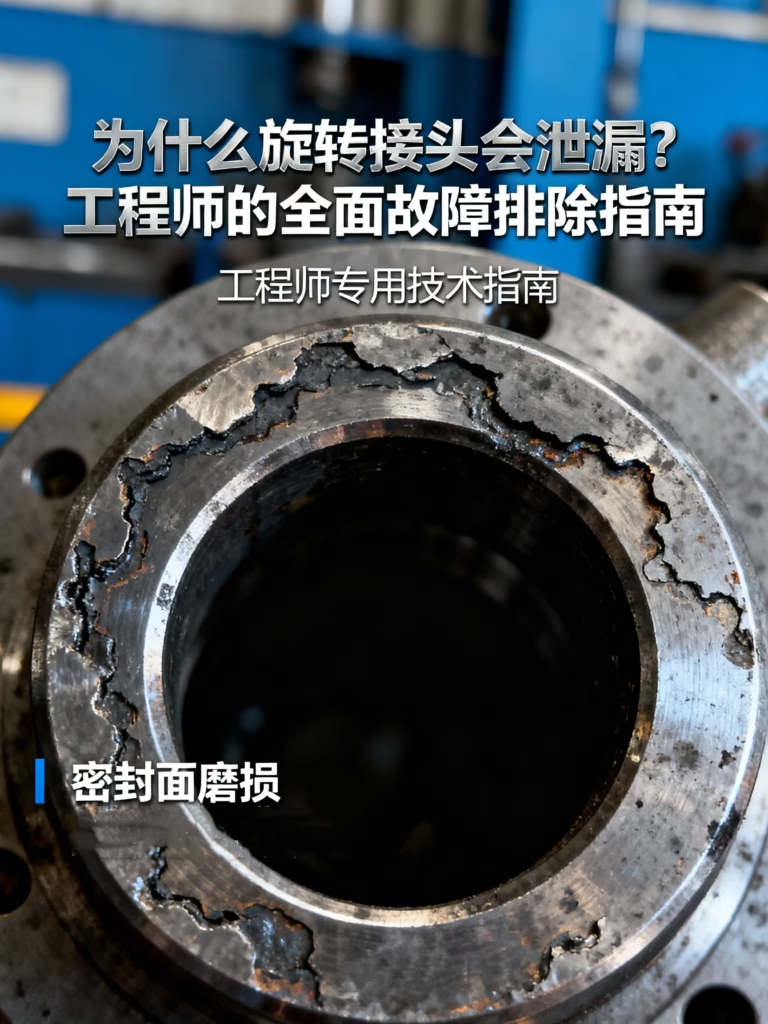

Seals in high-speed rotary unions need to be extremely reliable. Even a small amount of leakage can lead to significant problems in high-speed systems, including fluid loss, contamination of the working environment, or damage to the equipment. High-quality seals made from advanced materials like carbon, ceramic, or specialized polymers are used. These materials offer excellent wear resistance, low friction, and the ability to maintain a tight seal under high-speed and high-pressure conditions.

Design Features

To meet the demanding requirements of high-speed applications, rotary unions incorporate several key design features.

Precision – Machined Components

High-speed rotary unions feature precision-machined components to ensure smooth and accurate operation. The rotating shaft and stationary housing are manufactured with tight tolerances to minimize clearance between the moving parts. This precision machining reduces the likelihood of vibrations and ensures that the union can operate at high speeds without excessive noise or wear.

Advanced Bearings

Bearings play a crucial role in high-speed rotary unions. High-quality, high-speed bearings, such as angular contact ball bearings or ceramic ball bearings, are commonly used. These bearings offer low friction, high load-carrying capacity, and the ability to withstand high speeds. They are also designed to have a long service life, reducing the need for frequent maintenance or replacement.

Specialized Sealing Systems

As mentioned earlier, sealing is of utmost importance in high-speed rotary unions. Specialized sealing systems, such as double-acting seals or face seals, are employed. Double-acting seals can seal in both directions, providing enhanced protection against fluid leakage. Face seals, on the other hand, use a flat-surface contact between the rotating and stationary parts to create a tight seal. These seals are often self-adjusting, compensating for wear and maintaining a reliable seal over time.

Balanced Designs

To counteract the centrifugal forces generated at high speeds, many high-speed rotary unions have balanced designs. A balanced design distributes the mass of the rotating components evenly around the axis of rotation, reducing the unbalanced forces and minimizing vibrations. This not only improves the performance and reliability of the union but also extends the lifespan of the connected equipment.

Applications

High-speed rotary unions find applications in a wide range of industries.

Manufacturing Industry

In the manufacturing sector, high-speed rotary unions are widely used in machine tools. CNC (Computer Numerical Control) machines, such as lathes, milling machines, and grinders, often operate at high speeds to increase production rates and improve machining accuracy. The rotary union supplies coolant, lubricating oil, or compressed air to the rotating spindle, ensuring efficient cutting and reducing tool wear.

They are also used in injection molding machines. High-speed injection molding processes require the rapid transfer of hot oil or water for mold temperature control. The rotary union enables the continuous supply of these temperature-controlling fluids to the rotating mold components, ensuring consistent part quality and fast cycle times.

Printing Industry

The printing industry relies on high-speed rotary unions for various applications. In offset printing presses, the cylinders rotate at high speeds to transfer ink onto the paper. The rotary union supplies ink, fountain solution, and lubricating oil to the rotating cylinders, ensuring smooth operation and high-quality printing. Digital printing machines also use high-speed rotary unions to transfer fluids for printhead cleaning and maintenance, keeping the printing process running smoothly.

Packaging Industry

In the packaging industry, high-speed rotary unions are essential for equipment such as filling machines, labeling machines, and blow molding machines. Filling machines need to transfer liquids, such as beverages or sauces, at high speeds to meet production demands. The rotary union ensures a consistent and leak-free flow of the liquid to the moving containers. Labeling machines use rotary unions to supply adhesive or air for label application, while blow molding machines rely on them to transfer air or steam for shaping plastic containers at high speeds.

Aerospace Industry

The aerospace industry has stringent requirements for components, and high-speed rotary unions play a vital role in aircraft engines and other aerospace applications. In jet engines, rotary unions transfer fuel, lubricating oil, and cooling air to the rotating parts. These unions must be able to withstand extreme temperatures, high speeds, and harsh operating conditions to ensure the reliable operation of the engine. They are also used in other aerospace equipment, such as landing gear systems and auxiliary power units, where high-speed fluid transfer is required.

Energy Industry

In the energy sector, high-speed rotary unions are used in turbines, both in traditional power plants and renewable energy systems. In gas turbines, rotary unions transfer lubricating oil, cooling water, and fuel to the rotating components. And in wind turbines, they are used to transfer hydraulic fluid for pitch control systems, which adjust the angle of the turbine blades to optimize energy production. These unions need to be highly reliable to ensure the continuous operation of the turbines and minimize downtime.

Benefits

There are several significant benefits to using high-speed rotary unions in industrial applications.

Increased Productivity

By enabling equipment to operate at high speeds, high-speed rotary unions significantly increase productivity. Higher-speed machining reduces production times in manufacturing, enabling manufacturers to produce more parts within a given period. In the packaging industry, operators use high-speed filling and labeling machines to meet the demands of large-scale production and improve overall efficiency.

Improved Efficiency

These rotary unions also enhance the efficiency of industrial processes. The precise fluid transfer and reduced friction provided by high-speed rotary unions result in less energy consumption. For instance, in machine tools, the efficient delivery of coolant through a high-speed rotary union can reduce the energy required for cutting operations. Additionally, the ability to maintain a consistent fluid flow at high speeds ensures that equipment operates at optimal performance levels.

Extended Equipment Lifespan

The advanced design and high-quality components of high-speed rotary unions contribute to extending the lifespan of the connected equipment. By reducing vibrations, minimizing friction, and providing reliable sealing, these unions protect the rotating parts of the equipment from premature wear and damage. This, in turn, reduces the need for frequent repairs and replacements, saving both time and money in the long run.

Enhanced Product Quality

In many applications, high-speed rotary unions play a crucial role in maintaining product quality. In the printing and packaging industries, for example, a consistent and accurate fluid supply is essential for producing high-quality prints and packaging. High-speed rotary unions ensure that the right amount of ink, adhesive, or other fluids is delivered at the right time, resulting in better-quality products.

Selecting the Right High-Speed Rotary Union

Choosing the appropriate high-speed rotary union for your application is crucial for optimal performance and reliability.

Consider the Operating Conditions

The first step in selection is to carefully consider the operating conditions. Determine the maximum rotational speed, pressure, temperature, and type of fluid that the union will be exposed to. Different high-speed rotary unions have specific ratings for these parameters, and choosing a union that can handle the expected operating conditions is essential to prevent failure.

Evaluate the Fluid Type

The type of fluid being transferred also plays a significant role in the selection process. Different fluids have different properties, such as viscosity, chemical composition, and compatibility with materials. For example, if you are transferring a corrosive fluid, you will need a rotary union with seals and housing made from materials resistant to corrosion. Some fluids may also require special handling to prevent contamination or degradation, so make sure the selected union is suitable for the specific fluid.

Look at the Connection and Mounting Options

The connection and mounting options of the rotary union must match your equipment. Consider the type of connection, such as threaded, flanged, or quick-connect, and make sure you can easily integrate it into your existing system. The mounting style should also be compatible with the available space and requirements of your equipment. A proper connection and mounting will ensure a secure installation and prevent any issues during operation.

Check the Manufacturer’s Reputation

Finally, it’s important to choose a high-speed rotary union from a reputable manufacturer. A well-established manufacturer will have a track record of producing high-quality products and providing excellent customer support. Look for manufacturers that offer comprehensive product documentation, including technical specifications, installation instructions, and maintenance guidelines. Reading customer reviews and testimonials can also give you an idea of the manufacturer’s reliability and the performance of their products.

Installation and Maintenance

Proper installation and maintenance are essential for the long-term performance of high-speed rotary unions.

Installation

During installation, follow the manufacturer’s instructions carefully. Make sure you mount the union securely on the equipment and tighten all connections properly to prevent leaks. The alignment of the rotating shaft with the equipment’s rotating part is crucial. Misalignment can cause excessive vibrations, increased wear, and reduced performance. Use appropriate tools and techniques to achieve accurate alignment, and check the alignment after installation to ensure it meets the manufacturer’s specifications.

Maintenance

Regular maintenance is necessary to keep high-speed rotary unions in optimal condition. This includes inspecting the union for signs of leakage, wear, or damage. Check the seals and bearings regularly and replace them if they show any signs of deterioration. Lubricate the bearings according to the manufacturer’s recommendations to reduce friction and extend their lifespan. It’s also important to keep the union clean and free from debris, as dirt and contaminants can cause premature wear and affect the sealing performance. Additionally, monitor the operating parameters of the union, such as temperature, pressure, and rotational speed, to detect any abnormal changes early and take appropriate action.

Conclusion

High-speed rotary unions are indispensable components in a wide range of industrial applications. Their ability to withstand the challenges of high-speed rotation, transfer fluids efficiently, and enhance the performance of equipment makes them essential for modern industrial operations. By understanding their design, applications, benefits, selection criteria, and proper installation and maintenance procedures, you can make informed decisions and ensure the successful implementation of high-speed rotary unions in your industrial processes. Whether you are in manufacturing, printing, packaging, aerospace, or the energy industry, high-speed rotary unions can play a key role in driving productivity, efficiency, and quality in your operations.