HOW DOES A ROTARY JOINT WORK?WHAT IS THE ROTARY JOINT WORKING PRINCIPLE?

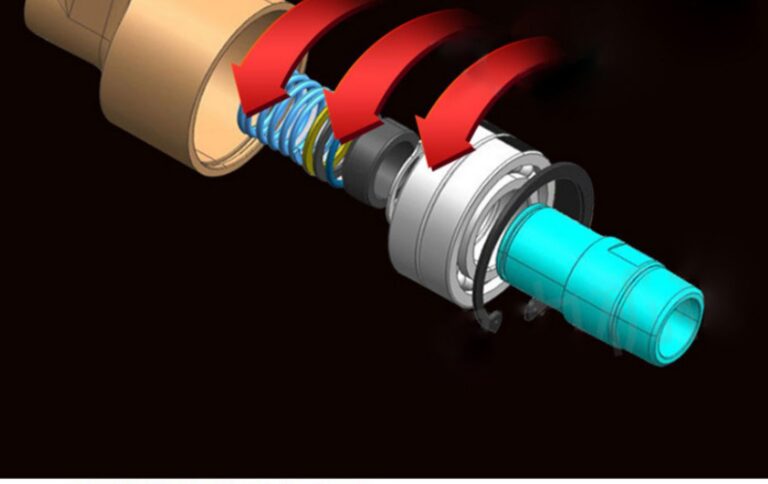

Rotary joints are essential components in many hydraulic and mechanical systems, particularly those involving rotating machinery. They enable the transfer of fluids (such as oil, water, or air) between stationary and rotating parts while maintaining a seal to prevent leakage. Here’s a detailed breakdown of the basic components and their functions:

Basic Components of Rotary Joints(hydraulic rotary swivel joint)

1. Housing

– Function: The housing is the stationary part of the hydraulic rotary swivel joint. It connects to the fluid supply and provides a stable base for the other components.

– Materials: Typically made from materials like steel, stainless steel, or brass, depending on the application and the type of fluid being transferred.

2. Shaft

– Function: The shaft is the rotating part of the hydraulic rotary swivel joint. It connects to the rotating equipment, such as a drum, roller, or spindle.

– Materials: Commonly made from steel or stainless steel to ensure durability and resistance to wear.

3. Seals

– Function: Seals are critical components that prevent fluid from leaking between the stationary housing and the rotating shaft. They must withstand pressure, temperature, and friction while maintaining a tight seal.

– Types:

– Lip Seals: Simple and effective, often used in low-pressure applications.

– Mechanical Face Seals: Provide a more robust seal for high-pressure and high-speed applications.

– Packing Seals: Consist of braided or molded materials that can be adjusted for a tighter seal.

– O-Rings: Used in conjunction with other seals to provide additional sealing.

– Materials: Commonly made from elastomers like NBR (Nitrile), FKM (Viton), or PTFE (Teflon), depending on the fluid and operating conditions.

4. Bearings

– Function: Bearings support the rotating shaft and ensure smooth, low-friction movement. They help to maintain the alignment of the shaft and reduce wear.

– Types:

– Ball Bearings: Suitable for light to medium loads and high speeds.

– Roller Bearings: Handle heavier loads and are more durable.

– Plain Bearings: Simple and cost-effective, often used in lower-speed applications.

– Materials: Typically made from steel or bronze, with some specialized applications using ceramic or plastic bearings.

Fluid Flow Paths

– Radial Flow: In radial flow designs, fluid enters the housing and flows radially outward to the rotating shaft. This design is common in applications where the fluid needs to be distributed evenly around the circumference of the shaft.

– Axial Flow: In axial flow designs, fluid flows along the axis of the shaft, either entering from one end and exiting from the other or flowing through the center of the shaft. This design is suitable for applications where the fluid path needs to be linear.

Key Considerations for Seals

– Pressure Resistance: Seals must be able to withstand the operating pressure of the system without deforming or failing.

– Temperature Resistance: Materials used for seals should be compatible with the temperature range of the fluid and the environment.

– Friction Management: Low-friction materials and designs help reduce wear and improve the efficiency of the rotary joint.

– Wear Resistance: Seals should be durable and resistant to wear to ensure long-term performance and reliability.

Maintenance and Inspection

– Regular Inspections: Check for signs of wear, leaks, or misalignment. Inspect seals, bearings, and the housing for any damage.

– Lubrication: Ensure that bearings and seals are properly lubricated to reduce friction and wear.

– Replacement: Replace worn or damaged components promptly to prevent further issues and ensure the continued performance of the rotary joint.

By understanding and properly maintaining these components, you can ensure that your hydraulic rotary swivel joint operate efficiently and reliably, minimizing downtime and extending the lifespan of your equipment.