“Cost-Effective Rotary Unions for Rubber and Plastic Machine” has been added to your cart.

View cart

Showing all 2 resultsSorted by price: high to low

-

Sale!

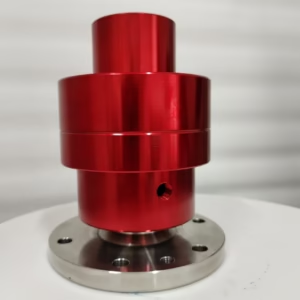

$175.00 Original price was: $175.00.$153.60Current price is: $153.60.

- Media: Water, oil, steam, hot oil, and other media used in molding processes

- Temperature: Ambient to +260°C (+500°F)

- Pressure Rating: Up to 345 bar (5,000 psi) or higher, depending on the model

- Rotational Speed: Up to 1,500 rpm

- Corrosion Resistance: Constructed from stainless steel and specialized alloys

-

Sale!

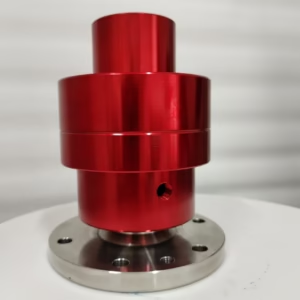

$30.00 Original price was: $30.00.$27.50Current price is: $27.50.

- Maximum pressure: 1.8MPA

- Maximum temperature :200 degrees Celsius

- Maximum speed :20RPM

- Applicable medium: steam