9000 Series Steam and Hot Oil Unions Rotary Union Manufacturing

Original price was: $130.00.$120.00Current price is: $120.00.

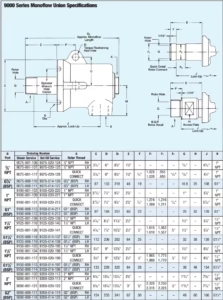

- Model number: 9000 series

- Connection: Male/flange

- Product name: 9000 Series Steam Rotary Union

- Medium: Steam / Hot Oil

- Standard: BSP/NPT

- Size: 3/4″~2″

- Maximum Pressure: 150PSI/10bar

- Maximum Temperature: 365°F /185°C

- Maximum Speed: 400 RPM℃

Description

9000 Series Steam Rotary Union Product Overview

Transform your industrial operations with the 9000 Series Steam Rotary Union, a premium solution designed for efficient fluid transfer in high-temperature and high-pressure environments. This rotary union is engineered specifically for applications involving steam, hot oil, and water, making it an essential component for industries such as printing, food processing, and manufacturing. environments.

Key Features

Durable Construction: The 9000 Series Steam and Hot Oil Unions are forged to ensure maximum durability and resistance to high-pressure applications, with a maximum pressure rating of 150psi/10bar.

Versatile Compatibility: These unions are available in various sizes, from 3/4″ to 2″, and are compatible with both BSP and NPT standards, making them suitable for a wide range of applications.

High-Temperature Resistance: With a maximum temperature rating of 365°F / 185°C, these unions can withstand extreme temperatures, making them ideal for use in steam and hot oil systems.

Customization Options: Youlite offers OEM customization support, allowing customers to tailor the unions to their specific needs and requirements.

Reliable Performance: With a 1-year warranty and a maximum speed of 400 rpm, these unions provide reliable performance and peace of mind for users, including those who require rotary join applications.

The 9000 Series Steam Rotary Union is ideal for numerous applications:

Steam Transfer in Printing Presses: Ensures efficient heat transfer for drying processes in flexographic and gravure printing operations.

Hot Oil Circulation in Food Processing: Used in cooking and heating systems where hot oil is circulated to maintain temperature consistency.

Water Cooling Systems: Supports cooling systems in manufacturing processes that require precise temperature control.

FAQ

What is the 9000 Series Steam Rotary Union?

The 9000 Series Steam Rotary Union is a mechanical device designed to connect stationary piping to rotating machinery. Allowing for the efficient transfer of steam, hot oil and water. It used in various industries, including printing and food processing. To ensure reliable fluid flow under high pressure and temperature conditions.

How does the advanced sealing technology work in the 9000 Series?

The 9000 Series features a Bellows Sealing System, which provides superior sealing performance throughout its operational life. This system minimizes leakage and enhances durability compared to traditional spring-based seals. Making it more resilient against debris in contaminated media.

What materials used in the construction of the 9000 Series?

The rotary union constructed with a cast iron housing and features stainless steel or plated sleeves. The shaft made of steel, ensuring robust performance even in harsh environments.

How does the dual flow configuration work in the 9000 Series?

The dual flow configuration allows for simultaneous input and output of fluids. This setup is particularly useful in applications where steam needs to be fed into a machine while allowing condensate or return fluids to exit through the same rotary union, optimizing space and efficiency.

What maintenance practices recommended for the 9000 Series?

Inspecting for leaks and ensuring proper alignment.

Checking seal integrity and lubricating bearings as needed.

Monitoring performance parameters such as pressure and temperature to prevent operational issues.

What innovations differentiate the 9000 Series from other rotary unions?

Innovations include its advanced sealing technology that resists debris buildup, superior alignment capabilities with dual bearings for sizes over 1¼ inches. Its ability to handle high-temperature applications effectively.