A08-1501-05L Rotoflux Rotary Union for Coolant Delivery Through the Machine Tool Spindle Center

Original price was: $100.00.$91.00Current price is: $91.00.

- Model: A10/A08

- Medium: Hydraulic oil/Coolant

- Pressure: ≤7.0 MPa

- Rotational Speed: ≤8000 RPM

- Temperature: <71°C (For high-temperature applications, please contact us)

Description

Product Overview A08-1501-05L Rotoflux Rotary Union

The A08-1501-05L Rotoflux Rotary Union is a precision-engineered rotary union designed for coolant delivery through the machine tool spindle center. It enables continuous and leak-free transfer of coolant from a stationary supply line into a rotating spindle, ensuring effective tool cooling, chip evacuation, and stable machining performance.

As a direct replacement for original Rotoflux rotary unions, the A08-1501-05L model offers identical mounting dimensions and comparable operating performance while providing a more cost-effective solution for CNC machine tool manufacturers and maintenance teams.

Designed for Through-Spindle Coolant Applications

The A08-1501-05L rotary union is specifically developed for through-spindle coolant systems, commonly used in modern CNC machining centers. By delivering coolant directly to the cutting zone, this rotary union helps:

-

Improve cutting efficiency

-

Extend tool life

-

Enhance surface finish quality

-

Reduce thermal deformation during high-speed machining

This makes it an essential component for high-performance milling, drilling, and tapping operations.

Key Features and Advantages

Stable Sealing at High Speed

The balanced sealing structure minimizes friction generated during rotation, allowing the rotary union to operate smoothly under continuous spindle rotation. This design reduces heat buildup and ensures long-term sealing stability.

Compact and Space-Saving Design

Machine tool spindles often offer limited installation space. The compact body design of the A08-1501-05L rotary union allows easy integration without modifying existing spindle structures.

Reduced Vibration and Wear

Internal spring-loaded components actively compensate for seal wear and help suppress turbulence and vibration caused by coolant flow, ensuring reliable operation under dynamic machining conditions.

Material Construction

-

Housing: High-strength aluminum or brass (optional)

-

Internal metal components: Stainless steel

-

Seal system: Engineered for water-based coolant delivery

The combination of corrosion-resistant materials ensures excellent durability when operating with emulsions, cutting fluids, and water-based coolants commonly used in CNC machining environments.

Ideal Replacement for A08-1501-05L Rotoflux Rotary Union

The A08-1501-05L model is designed as a 1:1 alternative to original Rotoflux rotary unions, offering:

-

Matching installation interfaces

-

Comparable coolant flow performance

-

Reliable sealing under continuous operation

-

Shorter lead times and competitive pricing

As a professional Chinese manufacturer specializing in rotary unions and rotary joints, we support OEM and aftermarket customers worldwide with consistent quality and flexible customization options.

Typical Applications

-

CNC machining centers

-

Milling and drilling machines

-

Tapping and high-speed cutting equipment

-

Spindle coolant systems

-

Machine tool retrofitting and maintenance

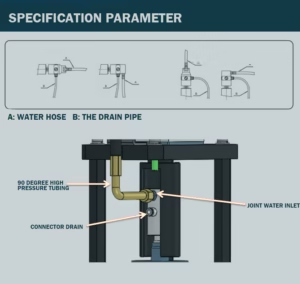

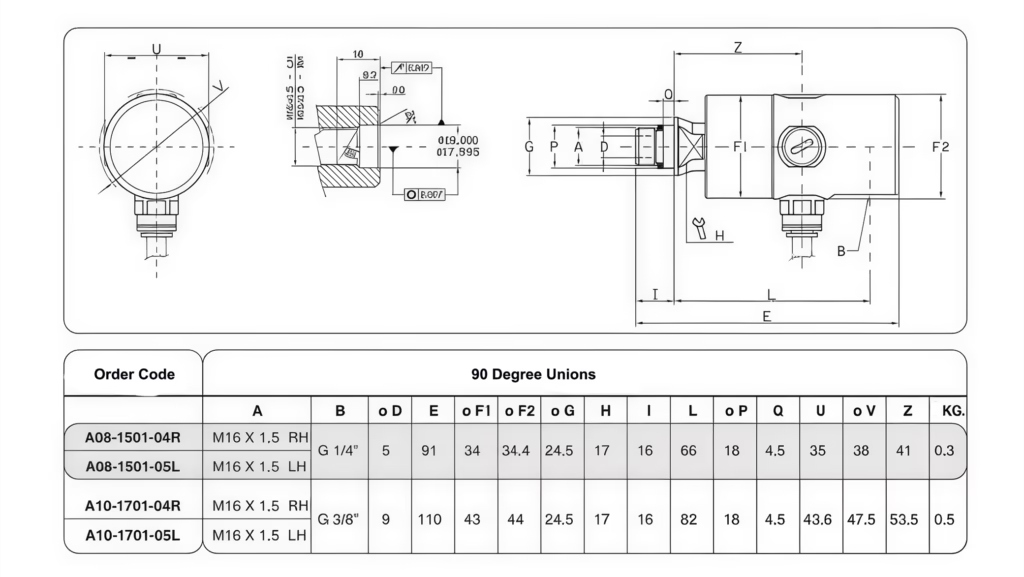

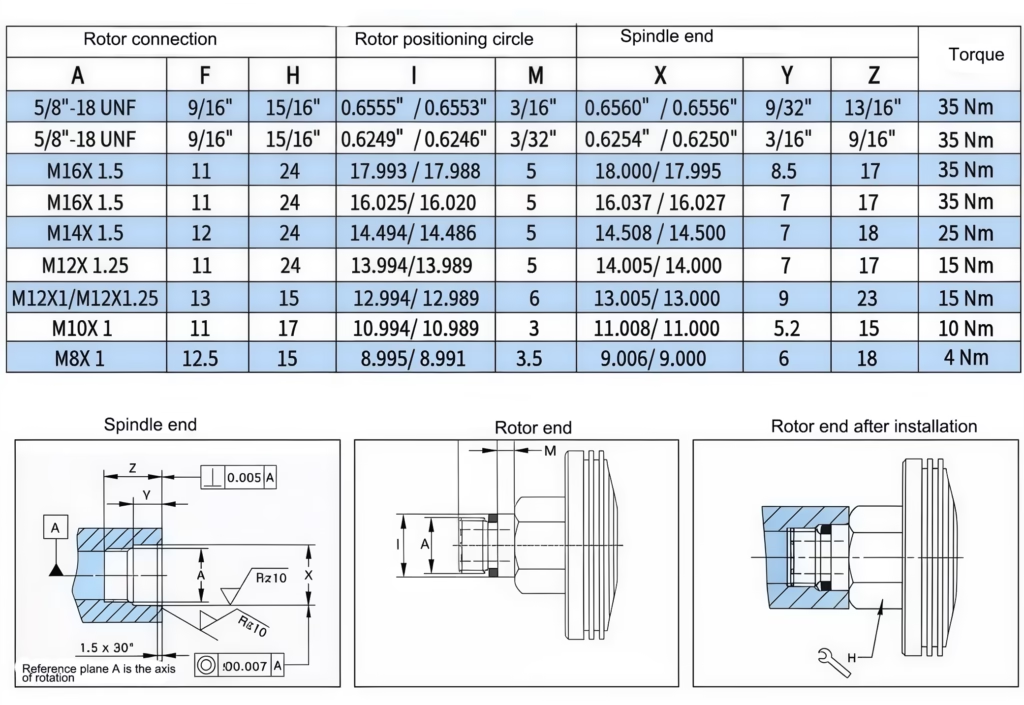

Installation Tolerances of A08-1501-05L Rotoflux Rotary Union

Special Note: When connecting the side piping, ensure the threaded end does not touch the internal sealing ring.

The interface between the spindle and the rotary joint must be machined to precise tolerances to ensure accurate and vibration-free operation.

The spindle end face must be machined according to the following dimensions and tolerances:

Reference Data

Spindle dimensions must meet the dimensional requirements shown in the respective rotary joint drawings (unless otherwise specified, all dimensions are in millimeters).

Why Choose Our A08-1501-05L Rotoflux Rotary Union

-

Proven solution for through-spindle coolant delivery

-

Compact, low-friction design for high-speed spindles

-

Durable materials for long service life

-

Cost-effective alternative to premium international brands

-

Technical support and OEM customization available

Frequently Asked Questions (FAQ)

1. What is the A08-1501-05L Rotoflux Rotary Union used for?

The A08-1501-05L Rotoflux Rotary Union is designed for coolant delivery through the machine tool spindle center. It transfers coolant from a stationary supply line into a rotating spindle, allowing coolant to reach the cutting tool directly for improved cooling, lubrication, and chip evacuation in CNC machining operations.

2. Is the A08-1501-05L a direct replacement for the original Rotoflux model?

Yes. We design the A08-1501-05L rotary union with identical mounting dimensions and equivalent performance specifications, enabling a true 1:1 replacement for original Rotoflux rotary unions. It installs without modification to the spindle or coolant system.

3. What types of coolant can this rotary union handle?

The A08-1501-05L rotary union is suitable for:

Water-based coolants

Cutting fluids

Emulsions are commonly used in CNC machine tools

Its material selection ensures corrosion resistance and stable sealing under continuous coolant flow.

4. Is the A08-1501-05L suitable for high-speed CNC spindles?

Yes. The rotary union features a balanced sealing structure and low-friction design, allowing stable operation under continuous spindle rotation. This makes it suitable for modern high-speed CNC machining centers.

5. How does the rotary union reduce leakage and seal wear?

The internal spring-loaded sealing system automatically compensates for wear during operation. In addition, the optimized internal flow path helps reduce turbulence and vibration caused by coolant flow, extending seal life and improving reliability.