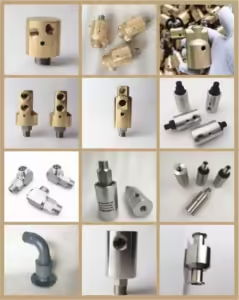

H Series Brass Swivel Joint – Compact Rotary Union for Cooling Systems

Original price was: $25.00.$21.00Current price is: $21.00.

- Product material: brass

- Applicable media: water, air, coolant, etc.

- Maximum temperature: 60℃ (high temperature can be customized by contacting customer service)

- Maximum speed: ≤100ORPM

- Using pressure: S16KG (1.6MPA)

- Product specifications: 1/4-3 inches (2 points-3 inches)

Description

Brass Swivel Joint: The Ultimate Solution for Fluid Control

The H Series Brass Swivel Joint is an advanced rotary connection solution meticulously engineered for cooling applications in a variety of industrial environments. Developed with compactness and efficiency in mind, this series offers a winning combination of small size, light weight, and low friction torque, making it ideal for high-speed, high-performance systems where space and energy efficiency are critical. The design minimizes torque during rotation and reduces wear on internal components, resulting in longer service life and reduced maintenance requirements.

According to the medium environment, we select various combinations of impregnated graphite, bronze, carbon tungsten, and silicon carbide to resist the influence of impurities such as rust, scaling, and broken saltpeter on the sealing surface. These materials carefully resist wear, corrosion, and erosion caused by common cooling system contaminants like rust particles, scale deposits, broken saltpeter, and other solid impurities that could compromise conventional seals.

Whether used in injection molding machines, die casting equipment, spindle cooling systems, or heat exchangers, the H Series Brass Swivel Joint delivers consistent, leak-free performance even under demanding conditions. It is an ideal choice for engineers seeking high-efficiency cooling solutions with minimal maintenance and maximum reliability.

- The shell is made of high-quality aluminum alloy

- Imported SKF, TIMKEN bearings, impregnated graphite rings

- High precision, low noise, high speed, good stability

- The bearing load is high, suitable for high-demand places

- Drawings can be issued according to customer requirements and customized processing

Key Features of the H Series Brass Swivel Joint

High-Quality Shell with Compact, Efficient Design

We build the outer shell from high-grade aluminum alloy and anodize it to offer excellent durability and corrosion resistance for long-term performance in humid or chemically aggressive environments. Its high-density, compact structure ensures efficient heat dissipation, while the lightweight body contributes to reduced system load and lower inertia during rotation. This design also helps achieve low-noise, zero-heat operation, making it ideal for high-precision applications.

Premium Materials for Enhanced Durability

We use selected materials for critical components to ensure long-lasting performance. We make the rotor shaft from 304 stainless steel, which provides excellent resistance to rust, wear, and high temperatures while maintaining mechanical strength under continuous rotation. This combination of materials guarantees both reliability and safety under a variety of working conditions.

Independent Internal Piping Structure

Inside the rotary joint, independent flow channels are designed to accommodate multiple media types or dual-flow systems. This separation prevents media mixing, enables more efficient cooling or heating cycles, and supports complex process requirements in industries such as plastics, die casting, or printing.

Easy and Precise Installation

Imported CNC equipment machines each joint with precision, producing clean, well-defined threads that provide a secure, leak-free connection. The refined design makes the rotary joint easy to install, even in tight or complex system layouts, and ensures long-term stability under vibration or dynamic load.

Application Scenarios

⚙️ CNC Machine Tools

Ensures stable coolant delivery to spindles or cutting tools.

Withstands frequent rotation and tool changes without leakage or performance drop.

🔩 Injection Molding Machines

Controls mold temperature efficiently by allowing seamless fluid circulation.

Prevents hot spots and improves molded part quality.

🧊 Die Casting Equipment

Supports cooling of dies and hydraulic actuators.

Compact structure allows installation in limited spaces.

🖨 Printing and Packaging Machines

Maintains roller temperature with precision coolant delivery.

Enhances print quality and reduces thermal distortion.

🌡 Automation Systems

Used in robots and rotary tables for air or fluid transmission without hoses tangling or twisting.

Why Choose Our Brass Swivel Joint?

Choosing our Brass Swivel Joint means opting for quality, reliability, and performance. Our commitment to excellence ensures that you receive a product that meets the highest industry standards while enhancing your operational efficiency.

Enhanced Equipment Longevity

By allowing smooth rotation and minimizing torque stress, our swivel joint helps reduce wear on hoses and fittings, extending the life of your equipment.

Improved Maneuverability

The swivel action increases flexibility in hose positioning, making it easier to navigate tight spaces and operate machinery efficiently.

Leak Prevention

The robust sealing mechanism ensures that fluids remain contained within the system, leading to safer operations and reduced environmental impact.

Cost-Effective Solution

With its durable construction and low maintenance requirements, our brass swivel joint provides long-term savings by reducing replacement costs and downtime.

FAQ

Q1: Can the H Series Brass Swivel Joint handle high-pressure applications?

A1: We design it to handle moderate pressures up to 25 bar (360 psi). For higher pressures, you may need to use specialized swivel joints.

Q2: Is this swivel joint suitable for fast rotation?

A2: No, it is best suited for low to moderate rotational speeds, typically up to 60 rpm.

Q3: What fluids can be used with this swivel joint?

A3: Compatible with water, oils, compressed air, and mild chemicals, depending on the seal material.

Q4: Can the swivel joint be used outdoors?

A4: Yes, brass construction offers good corrosion resistance, suitable for outdoor and industrial environments.

Q5: Are replacement seals available?

A5: Yes, seals made of NBR, EPDM, FKM, and FFKM are available for maintenance and extended service life.

Conclusion

The H Series Brass Swivel Joint offers an optimal balance of durability, flexibility, and corrosion resistance for industrial fluid transfer applications. Its robust brass construction, smooth 360° rotation, and reliable sealing make it an indispensable component in hydraulic, pneumatic, and fluid handling systems. Designed for low to moderate speeds and poor coaxiality, it ensures long-lasting, leak-proof operation, reducing maintenance costs and improving system efficiency.

For engineers and procurement specialists seeking a cost-effective, high-performance swivel joint, the H Series is the ideal choice.