High-Speed 5000 RPM Coolant Rotary Joint | Leakproof CNC Spindle Union

Original price was: $60.00.$58.00Current price is: $58.00.

- Medium: Coolant

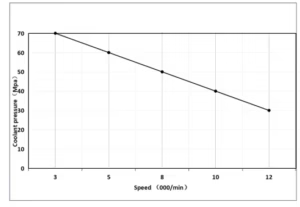

- Max.Pressure: 70bar

- Max.Speed: 12000rpm

- Max.Temperature: 80℃

- Recommended Filtration: 0.05mm

- Special Feature: Dry Operation Available

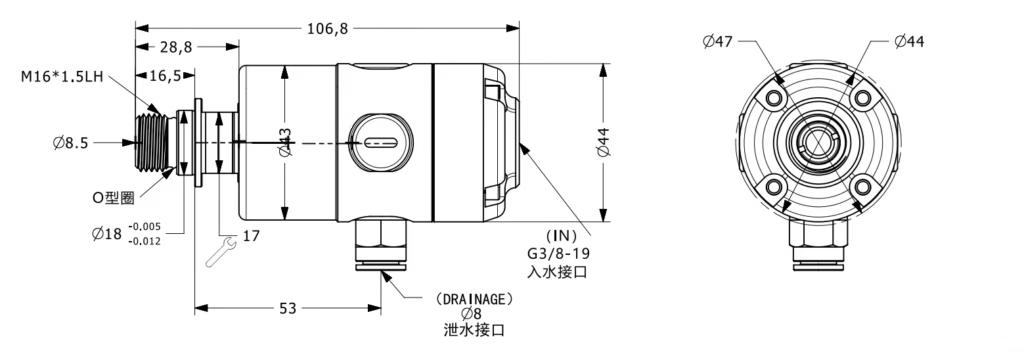

- Inlet Interface: G3/8 -19

- Drain Interface: Φ8

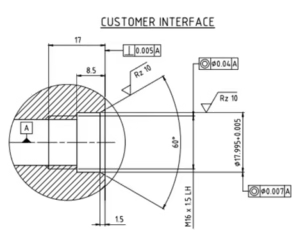

- Thread Specification: M16*1.5LH

Description

The High-Speed 5000 RPM Leakproof Coolant Rotary Joint is a state-of-the-art solution designed for precision machining and high-speed spindle applications. Built with advanced sealing technology, this coolant rotary joint ensures efficient transfer of coolant fluids under extreme speeds without leaks or downtime. It is an ideal replacement for leading brands, offering the same reliability and performance at a much more competitive price.

Whether you are operating CNC machine tools, milling centers, lathes, or grinding machines, this rotary joint guarantees uninterrupted coolant flow, longer spindle life, and improved machining accuracy.

Key Features of the High-Speed 5000 RPM Leakproof Coolant Rotary Joint

High-Load Adaptability

This coolant rotary joint is designed to handle extreme working conditions with superior performance. It can withstand a maximum speed of 12,000 RPM, a pressure of up to 70 bar (1015 PSI), and a temperature of 80°C (176°F). Such specifications make it the perfect choice for high-speed CNC machining centers, spindles, and other high-load equipment. Its robust build ensures efficient coolant transfer even during continuous, heavy-duty operations, helping manufacturers achieve higher productivity with minimal downtime.

Precision Connection Design

We design this rotary union for accuracy and leakproof reliability. Additionally, they equip it with a G3/8-19 inlet interface, a Φ8 drain outlet, and an M16*1.5LH threaded connection. This precision interface design guarantees a stable connection, strong sealing performance, and minimal coolant leakage risk. By preventing pressure drops and fluid loss, it ensures consistent coolant delivery, which is essential for maintaining machining accuracy and protecting sensitive spindle components.

Long-Term Durability Assurance

To enhance service life and minimize maintenance, the coolant rotary joint is designed with a recommended filtration precision of 0.05 mm. This fine-level filtration effectively blocks impurities, chips, and abrasive particles from entering the system, thereby protecting internal seals and mechanical components. The result is extended service life, greater reliability, and lower operating costs, making it a cost-effective alternative to premium rotary union brands while delivering comparable durability.

Flexible Operation Characteristics

Unlike conventional rotary unions, this high-speed coolant rotary joint supports dry running capability, allowing temporary emergency operation without coolant. This feature adds significant flexibility for machine operators, as it prevents accidental equipment damage in situations where coolant flow is interrupted. By accommodating both wet and dry conditions, the joint reduces operational risks, ensuring uninterrupted machining and enhanced machine safety.

Applications: Where Performance is Paramount

The Dann High-Speed Coolant Rotary Joint is the ideal solution for a multitude of demanding industrial applications:

CNC Machining Centers

The quintessential upgrade for vertical and horizontal milling machines, ensuring efficient chip evacuation and superior cooling in high-speed pocketing, profiling, and drilling operations.

High-Speed Spindles

A critical component for any machine tool utilizing through-spindle coolant is protecting the spindle from contamination and enabling peak performance.

Automotive Manufacturing

Perfect for the high-volume production of engine components, transmission parts, and other precision-critical elements where cycle time is money.

Aerospace Industry

Meets the stringent requirements for machining complex geometries from tough alloys like titanium and Inconel, where effective cooling is non-negotiable.

Medical Device Manufacturing

Delivers the precision and cleanliness required for producing intricate surgical instruments and implants from stainless steel and other medical-grade materials.

Mold and Die Making

Enhances surface finish and tool life when machining hardened tool steels, resulting in higher quality molds and dies with less manual polishing.

The Dann Advantage: A Commitment to Quality and Reliability

Choosing the Dann Coolant Rotary Joint means choosing peace of mind. Inferior rotary unions are a ticking time bomb, destined to fail at the most inopportune moment, leading to catastrophic spindle damage and production standstills. We address the primary failure points of standard rotary joints head-on:

Problem: Premature Seal Wear Leading to Leaks.

Our Solution: We use ultra-hard Silicon Carbide seals that are lapped to a mirror finish. Unlike softer carbon graphite seals, they resist abrasive particles in the coolant and can withstand the heat and pressure of high-speed operation without degradation, ensuring a long, leakproof life.

Problem: Bearing Failure from Coolant Contamination.

Our Solution: Our multi-stage sealing system, including advanced labyrinths and V-rings, provides a formidable barrier that protects the high-precision bearings from any coolant ingress. This redundant protection system is your spindle’s best defense.

Problem: Vibration and Instability at High RPMs.

Our Solution: Every [BRAND NAME] rotary joint is dynamically balanced to exacting tolerances. This precision balancing eliminates vibration at the source, leading to smoother operation, better surface finishes, and reduced wear on your machine’s spindle and tooling.

FAQ

Q1: What is a coolant rotary joint, and why is it important for CNC machines?

A coolant rotary joint, also known as a rotary union for coolant transfer, is a device that allows the passage of coolant or lubricants into a rotating spindle without leakage. It plays a critical role in CNC machining, milling, and grinding operations. It ensures that engineers cool tools and spindles efficiently. This process prevents overheating and, consequently, extends machine life.

Q2: What is the maximum speed and pressure this rotary joint can handle?

Our High-Speed Coolant Rotary Joint is engineered for extreme conditions. It can operate at speeds up to 12,000 RPM, handle 70 bar (1015 PSI) of pressure, and withstand temperatures up to 80°C (176°F). This makes it suitable for high-load and high-speed machining environments.

Q3: Is this coolant rotary joint compatible with all types of coolants?

Yes. We design the joint to work with water-based coolants, synthetic cutting fluids, and oil-based lubricants. Consequently, it offers versatile compatibility for various applications. Its precision seals ensure leakproof operation across a wide range of coolant types, making it versatile for different machining applications.

Q4: How does this product compare to leading brands like Deublin?

Our coolant rotary joint is a cost-effective alternative to brands like Deublin, offering the same leakproof performance, high-speed capability, and durability, but at a much more competitive price. Many customers have switched to our product without compromising on quality.

Q5: Does the rotary joint require frequent maintenance?

No. Thanks to its precision filtration (0.05 mm recommended) and wear-resistant sealing materials, this rotary joint requires minimal maintenance. Routine inspections every 6–12 months are recommended, but the product is designed for long-term durability and low operating costs.

Q6: Can it run without coolant in case of an emergency?

Yes. This rotary joint supports dry operation, meaning it can temporarily run without coolant. This feature reduces the risk of spindle damage during unexpected coolant interruptions and provides extra safety in high-load machining conditions.

Customer Testimonials

⭐ John M., CNC Operator (USA):

“This coolant rotary joint has been running at 4800 RPM for 6 months with zero leaks. It performs just like Deublin but at nearly half the price. Very satisfied!”

⭐ Li Wei, Machine Shop Manager (Germany):

“We replaced all of our spindle coolant rotary unions with these units. The installation was easy, performance is excellent, and maintenance has gone down dramatically.”

⭐ Ahmed K., Automotive Manufacturer (UAE):

“High-speed stability is impressive. We were concerned about leakage at 5000 RPM, but it’s rock solid. Excellent product for production lines.”

🛒 Ready to Upgrade Your CNC Machine with a Reliable Coolant Rotary Joint?

If you’re looking for a leakproof, high-speed, and cost-effective coolant rotary joint, this model is the perfect choice for your CNC machining center, spindle, milling, or grinding equipment.

👉 Don’t settle for overpriced alternatives — get the same high-performance quality at a more competitive price today!

📦 Fast delivery, OEM/ODM customization, and global shipping available.

✅ Click “Order Now” to improve your machining efficiency and reduce maintenance costs with the High-Speed 5000 RPM Leakproof Coolant Rotary Joint.