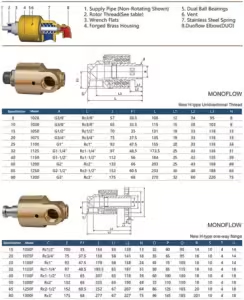

H Mono Flow Rotary Union For Water Treatment Equipment

Original price was: $15.00.$12.00Current price is: $12.00.

- Media Types: Water, Oil, Air

- Max Speed: Up to 3,500 RPM

- Max Pressure: Up to 3,625 psi

- Temperature Range: Up to 250°F (121°C)

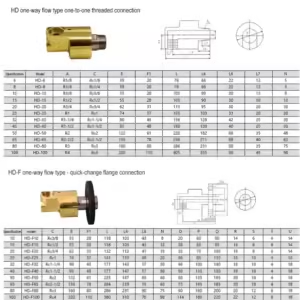

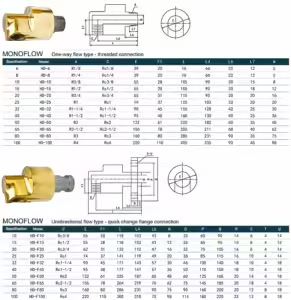

- Connection Types: NPT sizes from 1/4″ to 1″

Description

H Mono Flow Rotary Union: Product Overview

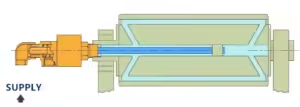

Introducing the H Mono Flow Rotary Union, a high-performance solution specifically designed for efficient fluid transfer in rotating applications. This rotary union is engineered to provide reliable, leak-free operation while allowing for continuous rotation, making it an essential component in various industrial settings, including cooling systems, hydraulic machinery, and manufacturing processes.

Key Features

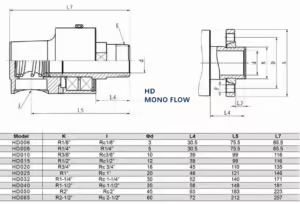

Mono Flow Design: The H Mono Flow Rotary Union features a single channel for fluid transfer, ensuring a straightforward and efficient design that minimizes potential leak points.

High Performance: Capable of operating at speeds up to 3,500 RPM and pressures reaching 3,625 psi, this rotary union built to handle demanding applications with ease.

Durable Construction: Made from high-quality materials such as stainless steel or brass, the H Mono Flow designed to withstand harsh operating conditions while resisting corrosion and wear.

Advanced Sealing Technology: Equipped with balanced mechanical seals made from durable materials like carbon graphite and silicon carbide, ensuring reliable sealing performance and longevity.

The HD Mono Flow Rotating Joint is perfect for:

Cooling Systems: Efficiently transfers cooling fluids in machinery and equipment.

Manufacturing Processes: Ensures reliable fluid delivery in continuous production lines.

Hydraulic Systems: Provides seamless integration in hydraulic machinery for optimal performance.

FAQ

What is the HD Mono Flow Rotating Joint?

The HD Mono Flow Rotating Joint is a specialized rotary union designed for cooling applications, allowing for the efficient transfer of fluids such as water, hydraulic oil, and coolant while enabling rotational movement. Its compact design and lightweight construction make it ideal for various industrial settings.

What industries commonly use the HD Mono Flow Rotating Joint?

Plastic Manufacturing: For cooling processes in calendering equipment.

Hydraulic Systems: To manage fluid transfer in hydraulic machinery.

Coating Machinery: Ensures efficient application of coatings by managing fluid flow.

What are the pressure and temperature ratings for the HD Mono Flow?

The HD Mono Flow Rotating Joint typically operates at a maximum pressure of up to 1.0 MPa and can handle temperatures ranging from 0°C to 250°C (32°F to 482°F), depending on the specific model and application.

How does the sealing mechanism work in the HD Mono Flow?

The sealing mechanism utilizes advanced plane sealing technology, which incorporates high-quality materials such as impregnated graphite and tungsten carbide to resist wear from impurities like rust and debris. This design ensures a reliable seal that minimizes leakage during operation.

What maintenance practices recommended for the HD Mono Flow?

Inspecting seals and bearings for wear.

Keeping the joint clean to prevent contamination.

Ensuring that compatible fluids are used to avoid damage.

Following manufacturer guidelines for specific maintenance schedules can extend the joint’s lifespan.

What are some common applications for the HD Mono Flow Rotating Joint?

Cooling Systems: Managing cooling fluids in machinery and equipment.

Hydraulic Equipment: Facilitating fluid transfer in hydraulic systems.

Industrial Mixers: Ensuring continuous fluid flow during mixing processes.

How does the performance of the HD Mono Flow compare to other rotary joints?

The HD Mono Flow offers significant advantages such as lower friction torque, compact design, and advanced sealing technology compared to traditional rotary joints. These features contribute to enhanced efficiency, reduced maintenance needs, and improved operational reliability.