China Hydraulic Swivel Joint Rotary Union Manufacturer

Original price was: $25.00.$21.00Current price is: $21.00.

- Connection: Male

- Product name: Hydraulic swivel joint

- Thread: BSPP BSPT NPT

- Surface treatment:machining

- Medium:Water/ Air/Hydraulic Oil

- Maximum pressure:35MPa

- Maximum speed:120RPM

- Tolerable temperature: 120℃

Description

Hydraulic Swivel Joint: The Ultimate Solution for Fluid Conveyance

Hydraulic swivel joint is essential components in fluid power systems, designed to enhance efficiency and durability. These innovative joints allow for flexible movement in piping systems, reducing wear and tear on hoses and ensuring reliable operation under various conditions. Whether you’re in construction, agriculture, or industrial applications, hydraulic swivel joints provide the versatility and performance you need.

Key Features and Benefits

Extended Hose Life: By minimizing twisting and kinking of hoses, hydraulic swivel joints significantly extend the lifespan of your fluid-conducting systems

Design Versatility: These joints simplify plumbing configurations, allowing for more efficient system designs with fewer components needed.

Shock Absorption: Hydraulic swivel joints effectively absorb system shocks, reducing downtime and maintenance costs associated with equipment failure.

Temperature and Pressure Resistance: Capable of handling extreme temperatures from -50°C to +260°C and high pressures, these joints are ideal for demanding environments.

Compatibility: Designed to work seamlessly with various fluids, hydraulic swivel joints ensure compatibility across different applications, enhancing system reliability.

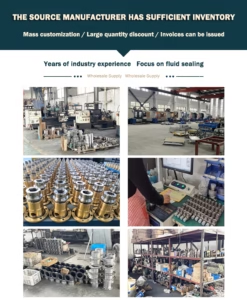

Why Choose Our Hydraulic Swivel Joints?

At Dann, we offer a comprehensive range of hydraulic swivel joints from leading manufacturers. Our products are rigorously tested to meet industry standards, ensuring reliability and performance. Our experts is ready to assist you in selecting the right joint for your specific needs, providing tailored solutions. What is a hydraulic swivel joint?

What is a hydraulic swivel joint?

A hydraulic swivel joint is a mechanical device that allows for uninterrupted fluid transfer under high pressure while facilitating rotation. It enables equipment to rotate smoothly while maintaining fluid flow, making it crucial in various industries like manufacturing, oil and gas and construction.

How does a hydraulic swivel joint work?

Hydraulic swivel joints work by having a shaft that rotates while the housing remains stationary. The shaft contains drilled holes that define the fluid flow path, ensuring continuous fluid transfer during rotation.

What are the applications of hydraulic swivel joints?

Hydraulic swivel joints are used in numerous industries, including maritime, manufacturing, agriculture , oil and gas, automotive, construction and wind energy (turbines).

What are the benefits of using hydraulic swivel joints?

The benefits include enhanced equipment life by reducing wear and tear, greater flexibility in motion, prevention of fluid leakage, and a broad range of applications across different industries.

How do you maintain a hydraulic swivel joint?

Maintenance involves regular inspections, timely replacement of worn components like seals. Ensuring proper alignment and lubrication to maintain performance and longevity.

What types of fluids can hydraulic swivel joints handle?

Hydraulic swivel joints can handle a variety of fluids, including oil, water, steam, and gas, making them versatile across different applications.

What materials hydraulic swivel joints made of?

They typically made from carbon steel or stainless steel, which provide durability and resistance to wear.

Can hydraulic swivel joints operate under high pressure?

Yes, hydraulic swivel joints are designed to withstand high pressures, ensuring reliable operation in systems that require continuous fluid flow under intense pressure conditions.

What are some common issues with hydraulic swivel joints?

Common issues include seal degradation, misalignment, and improper maintenance, which can lead to leakage or reduced performance. Regular inspection and maintenance are crucial to mitigate these issues