Rotary Union for Printing Machinery

Original price was: $20.00.$16.00Current price is: $16.00.

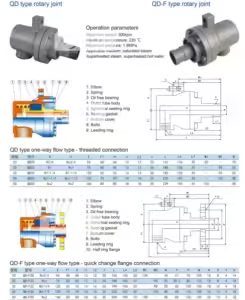

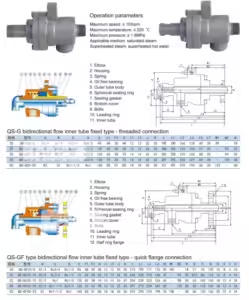

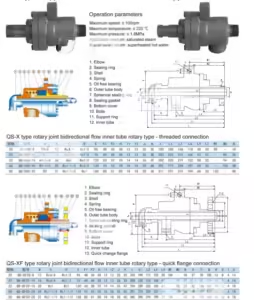

- Connection: Male

- Product name: Rotary union for Printing Machinery

- Medium: Steam

- Standard: ANSI

- Color: Customized

- Tolerable temperature: 220℃

- Maximum speed: 100RPM

- Apply pressure: 1.8MPA

Description

Product Overview: Rotary Union for Printing Machinery

Product Overview: Rotary Union for Printing Machinery

Elevate your printing operations with our Rotary Union for Printing Machinery, engineered to deliver seamless fluid transfer and enhance the efficiency of your printing processes. This essential component is designed for various printing applications, including flexographic, gravure, and offset printing, ensuring consistent performance under demanding conditions.

Durable Construction: The Q series steam swivel joints made with a robust casting technics, ensuring a long-lasting performance and resistance to high temperatures up to 220 degrees Celsius.

Durable Construction: The Q series steam swivel joints made with a robust casting technics, ensuring a long-lasting performance and resistance to high temperatures up to 220 degrees Celsius.

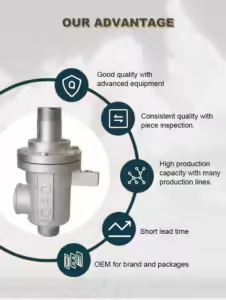

Customization Options: This product offers OEM customized support, allowing customers to tailor the color, shape, and size to meet specific requirements, making it an ideal choice for various industrial applications.

High-Pressure Resistance: With a tolerable pressure of 1.8 MPA, this rotary union is suitable for high-pressure steam applications, providing a reliable connection in demanding environments.

Efficient Operation: The Q series steam swivel joints have a maximum speed of 100 RPM, ensuring efficient operation and minimizing downtime in industrial processes.

Wide Compatibility: This product adheres to the ANSI standard and is available in a reducing shape with a square head code, making it compatible with a wide range of pipe fittings and plumbing systems, including those used by a specific company that requires a customized solution.

The Rotary Union for Printing Machinery is crucial in various applications:

The Rotary Union for Printing Machinery is crucial in various applications:

Flexographic Printing: Ensures efficient ink transfer and temperature control for high-quality prints on flexible materials.

Gravure Printing: Supports fluid transfer in gravure presses, maintaining consistent ink flow for superior print quality.

Offset Printing: Used in sheet-fed and web-fed offset machines to manage steam or water cooling systems effectively. Why Choose Us?

Why Choose Us?

With years of expertise in providing fluid handling solutions tailored for the printing industry, we committed to delivering products that enhance operational efficiency. Our rotary unions manufactured using cutting-edge technology to ensure they meet the highest standards of quality and reliability.

What is a Rotary Union for Printing Machinery?

What is a Rotary Union for Printing Machinery?

A Rotary Union for Printing Machinery is a device that connects stationary piping to rotating components in printing machines. It allows for the efficient transfer of fluids such as ink, water and steam. This component is essential for maintaining consistent fluid flow during various printing processes, including flexographic and gravure printing.

How do Rotary Unions improve efficiency in printing operations?

Rotary Unions facilitate uninterrupted fluid transfer, which minimizes downtime and enhances production rates. By ensuring optimal temperature and pressure management, they help maintain print quality and reduce waste during the printing process.

What types of fluids can Rotary Unions handle in printing applications?

Rotary Unions designed to handle various fluids, including ink, water, steam, and coolant. This versatility makes them suitable for different printing technologies, ensuring reliable performance across multiple applications.

What are the key applications of Rotary Unions in the printing industry?

Flexographic Printing: Used for transferring ink to flexible substrates.

Gravure Printing: Supports fluid transfer to ensure consistent ink flow.

Offset Printing: Manages steam or water cooling systems in sheet-fed and web-fed presses.

What materials are commonly used in the construction of Rotary Unions for printing machinery?

Rotary Unions typically constructed from corrosion-resistant materials like stainless steel. They feature seals made from durable materials such as carbon graphite or fluorocarbon to ensure longevity and prevent leakage under high-pressure conditions.

How do Rotary Unions contribute to sustainability in printing?

By optimizing fluid management and reducing energy consumption during processes like drying and cooling, Rotary Unions help lower the environmental impact of printing operations. Efficient designs lead to less waste and better resource utilization.

What maintenance practices are recommended for Rotary Unions in printing machinery?

Regular maintenance should include inspections for leaks, ensuring proper lubrication of bearings, and monitoring seal integrity. These practices help extend the service life of the rotary union and prevent costly operational disruptions.

Can Rotary Unions be customized for specific printing applications?

Yes, many manufacturers offer customizable rotary unions tailored to meet specific operational requirements. Such as size, pressure ratings, and fluid types, ensuring optimal performance in unique applications within the printing industry.

What innovations are shaping the future of Rotary Union technology in printing?

Innovations include advanced sealing technologies that improve leak prevention, materials that enhance corrosion resistance, and designs that optimize energy efficiency. These developments aim to reduce operational costs while improving sustainability in printing processes.

How do Rotary Unions impact print quality in various printing processes?

By ensuring consistent fluid flow and temperature control during critical processes like drying and cooling, Rotary Unions directly influence the quality of printed materials. Proper temperature management leads to better finishes and improved overall product characteristics.