SNS Type Steam High Temperature Rotary Union

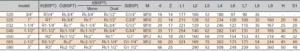

- Medium: Steam, Hot Oil

- Max Temperature: 260°C

- Max Pressure: 3.5 MPa

- Max Speed: 100 RPM

- Seal Type: Convex Spherical Seal

- Material: Stainless Steel/Carbon Graphite

- Applications: Corrugated Paper Machines

Description

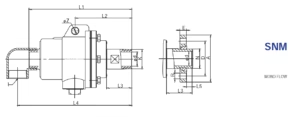

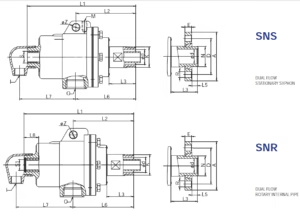

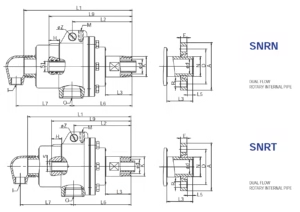

SNS Type Steam High Temperature Rotary Union

Upgrade your corrugated paper production line with the SNS Type Steam High Temperature Rotary Union, engineered for demanding high-speed and high-temperature steam applications in modern corrugators. This rotary union is designed to deliver outstanding steam transfer efficiency, exceptional durability, and minimal maintenance, ensuring your dryer rolls operate at peak performance.

The SNS Type Steam High Temperature Rotary Union is a self-supported rotary joint specifically developed for corrugated paper machines that require a reliable steam supply at elevated temperatures and pressures. It facilitates the continuous flow of high-temperature steam into rotating dryer cylinders while efficiently removing condensate through compatible siphon systems. Its robust construction and advanced sealing technology make it ideal for high-speed corrugators operating under harsh thermal and mechanical conditions.

Product features of SNS Type Steam Rotary Union

- True spherical seal design

- Standard graphite or antimony-impregnated graphite sealing material

- Double oil-free bearing support

- Maximized support spacing

- Extend seal life and improve reliability

- Easy to replace

- Rotary or fixed siphon

Key Features of Our SNS Type Steam Rotary Union

1. Superior Sealing Mechanism

One of the standout features of our SNS Type Steam Rotary Union is its advanced sealing mechanism. We utilize state-of-the-art sealing materials, including high-performance graphite and PTFE (Polytetrafluoroethylene). These materials are chosen for their excellent heat resistance, chemical stability, and low-friction properties.

The multi-layer sealing system in our rotary union creates a tight barrier against steam leakage, even under extreme operating conditions. This not only improves the energy efficiency of the connected equipment but also reduces the risk of environmental contamination and safety issues associated with steam escape. The sealing mechanism is designed to be long-lasting, minimizing the need for frequent replacements and maintenance.

2. High-Quality Construction Materials

Our SNS Type Steam Rotary Union is constructed from premium-grade materials to ensure durability and reliability. The body of the union is typically made from high-strength stainless steel or brass, which offers excellent corrosion resistance. Stainless steel, in particular, is highly resistant to rust and chemical corrosion, making it suitable for use in a wide range of industrial environments, including those with aggressive chemicals or high humidity.

The internal components, such as the rotor and stator, are precision-machined from alloy steels. These materials are heat-treated to enhance their strength and wear resistance, allowing the rotary union to operate smoothly and efficiently over an extended period. The use of high-quality materials also contributes to the overall longevity of the product, reducing the total cost of ownership for our customers.

3. Precision Engineering

Each SNS Type Steam Rotary Union is the result of meticulous precision engineering. Our manufacturing processes incorporate the latest CNC (Computer Numerical Control) machining techniques, ensuring that every component is produced to exacting standards. The precise alignment of the internal parts minimizes friction and wear, which in turn reduces energy consumption and extends the service life of the rotary union.

The design of our SNS Type Steam Rotary Union also takes into account factors such as thermal expansion and contraction. This ensures that the union can operate effectively in fluctuating temperature conditions without compromising its performance or integrity. The precision – engineered components work in harmony to provide a stable and reliable connection for steam transfer.

4. Wide Range of Temperature and Pressure Ratings

Our SNS Type Steam Rotary Union designed to handle a broad spectrum of operating conditions. It can withstand high temperatures, typically ranging from ambient up to 300°C (572°F), depending on the specific model and configuration. Similarly, it can operate under high pressures, with pressure ratings reaching up to 40 bar (580 psi) in some variants.

This wide range of temperature and pressure ratings makes our rotary union suitable for diverse industrial applications. Whether it’s a high-temperature steam-based drying process in the paper industry or a high-pressure steam sterilization application in food industry, our SNS Type Steam Rotary Union can perform reliably.

5. Customization Options

We understand that different industries and applications have unique requirements. To meet these diverse needs, we offer a comprehensive range of customization options for our SNS Type Steam Rotary Union. Customers can choose from various connection types, including flanged, threaded, and quick-connect fittings, to ensure compatibility with their existing equipment.

In addition, we can customize the size, shape, and internal passage design of the rotary union to optimize steam flow and performance. Our team of experienced engineers works closely with customers to understand their specific requirements and develop tailored solutions that meet or exceed their expectations.

Item Value

Speed 50-250 RPM

Pressure 32 Bar

Size 3/4''-8''

Temperature 280℃

Medium Steam

Applications of SNS Type Steam Rotary Union

1. Paper Manufacturing Industry

2. Textile Industry

3. Rubber Processing Industry

4. Food Processing Industry

Solving Critical Challenges in SNS Type Steam Rotary Union

For manufacturers operating corrugated paper lines in high-temperature steam environments (220°C+), outdated rotary unions often become a liability, compromising productivity, increasing costs, and risking quality consistency. Below are the primary pain points faced by buyers and how the SNS Type Steam High Temperature Rotary Union delivers targeted solutions:

1. Seal Failure and Excessive Leakage in Extreme Heat

Buyer Pain Point

Traditional rotary unions using graphite or PTFE seals degrade rapidly above 200°C, leading to:

High leakage rates (0.5–1L/h at 2.0MPa), wasting up to 5,000kWh of energy annually per unit

Frequent seal replacements (every 3–6 months), causing unplanned downtime and costly material waste

Steam contamination from lubricant degradation, leading to paper defects like brown spots or uneven moisture

Solution: Nanocrystalline Alloy Sealing Technology

Temperature Resistance Revolution: Patented nanocrystalline alloy seals (耐温 260°C) resist thermal fatigue and carbonization, maintaining structural integrity 3x longer than conventional materials

Adaptive Sealing Design: 0.005mm precision-ground sealing faces with bellows compensation automatically adjust for shaft expansion (±2mm), achieving a leakage rate ≤0.03L/h—90% lower than standard models

2. Lubrication Breakdown and Bearing Failure

Buyer Pain Point

In high-temperature environments:

Grease-based bearings degrade quickly, causing friction-induced heat spikes and eventual seizure.

Regular lubrication (weekly to bi-weekly) is labor-intensive and risks steam contamination.

Short bearing lifespan (1,500–3,000 hours) leads to frequent replacements and production interruptions.

Solution: Full-Ceramic Self-Lubricating Bearings

Dry-Run Capability: Zirconia ceramic bearings operate without lubrication up to 300°C, eliminating contamination risks and maintenance needs

Industrial Durability: Tested for 15,000+ hours of continuous operation, with an MTBF of 10,000 hours—3x the life of steel bearings

Vibration Control: Dynamic balance grade G2.5 ensures stable operation at 600 rpm, reducing mechanical stress on connected components

3. Inefficient Heat Transfer and Energy Waste

Buyer Pain Point

Poor steam flow design in traditional unions results in:

Significant pressure drop (≥0.5MPa), reducing steam velocity and heat transfer efficiency

Condensate accumulation in cavities, causing thermal lag and uneven roll temperatures (±5°C deviation)

Fouling from fiber impurities requires monthly shutdowns for cleaning

Solution: Honeycomb Flow Channel Design

Thermal Efficiency Boost: Bionic honeycomb structure increases steam flow area by 25%, reducing pressure drop by 35% and improving heat transfer efficiency to 99%

Anti-Fouling Protection: Teflon-coated interiors and 60° angles accelerate condensate drainage, while diamond-like carbon (DLC) coatings resist fiber adhesion 6x better than standard surfaces

Uniform Temperature Control: Ensures roll temperature variation ≤1°C, critical for maintaining paper moisture consistency (±1.5%) and corrugation precision

4. Compatibility Issues with High-Speed/High-Pressure Machines

Buyer Pain Point

Many manufacturers struggle with:

Incompatible dimensions for imported machines (e.g., BHS, Fosber) requiring costly custom modifications

Instability at high speeds (>300m/min), leading to vibration-induced seal wear and premature failure

Limited pressure tolerance, forcing downgraded steam parameters and reduced production capacity

Solution: Universal High-Performance Design

Full-Specification Coverage: Available in DN32–DN150 with RJ flange/threaded connections, directly replacing 98% of global brand models (no retrofitting needed)

High-Pressure Readiness: SNS-HX series supports 2.5MPa working pressure and 260°C continuous operation, with surge tolerance up to 280°C for short periods

Dynamic Balance Optimization: Engineered for 600 rpm operation with vibration amplitude ≤1.2mm/s, ensuring seamless integration with high-speed production lines

5. Lack of Predictive Maintenance in Hazardous Environments

Buyer Pain Point

Without real-time monitoring:

Hidden failures (e.g., gradual seal wear, bearing micro-cracks) go undetected until catastrophic breakdowns

Emergency shutdowns average 8–12 hours, causing production losses of $15,000+ per incident

Manual inspections in high-temperature zones pose safety risks for maintenance teams

Solution: Intelligent Thermal-Vibration Monitoring (Standard Feature)

Real-Time Sensing: Built-in K-type thermocouples (±0.5°C accuracy) and MEMS vibration sensors (0.1mm/s resolution) monitor critical parameters 24/7

Proactive Alerts: SNS-iGuard chip triggers visual/audio alarms and DCS system signals when:

Temperature rise >5°C/min (indicating seal degradation)

Vibration >2.0mm/s (signaling bearing misalignment)

Data-Driven Maintenance: Cloud-based platform generates predictive maintenance reports, reducing unplanned downtime by 60%

FAQ of SNS Type Steam Rotary Union

FAQ of SNS Type Steam Rotary Union

Q1: How often should seals be replaced?

A: Under normal conditions, replace seals every 8,000–10,000 operating hours. Harsh environments may require more frequent maintenance.

Q2: Can this rotary union handle condensate removal?

A: Yes! Our multi-passage design separates steam supply and condensate return in a single unit.

Q3: What if my machine has non-standard flange sizes?

A: We provide OEM customization—share your specs, and we’ll engineer a solution in 7–10 days.

Q4: How to troubleshoot steam leakage?

A: Check seal integrity and alignment first. Our team offers free remote diagnostics for registered clients.