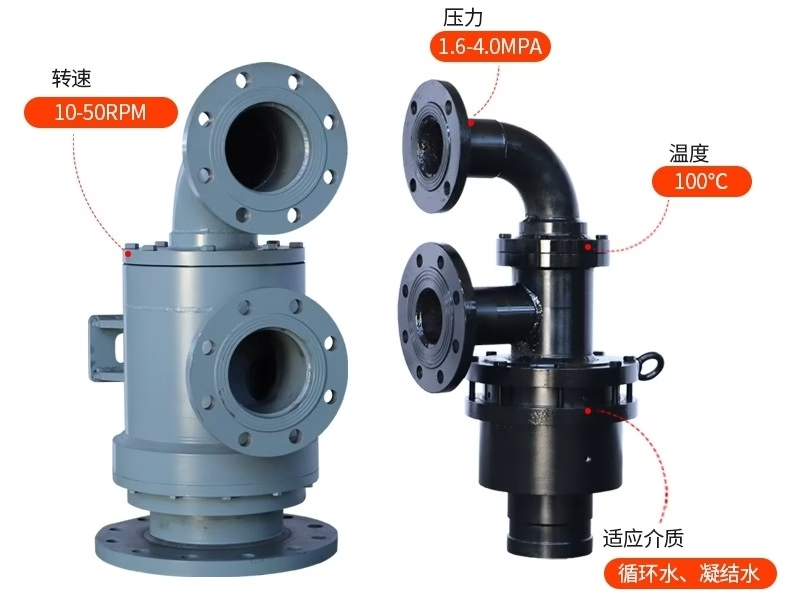

Cooling Water Roller Slag Rotary Cooler Tire Rrotary Joint

Original price was: $35.00.$30.00Current price is: $30.00.

- Technics: Casting

- Thread Standard: NPT\Bsp\Mpt(Customizable)

- Thread Rotation: Left, Right

- Connection Mode: Threaded/Flange Connection

- Max.Speed: 10-50RPM

- Max. Pressure: 1.6-4.0MPA

- Max. Temperature: 100°C

- Medium: Water, hot water, steam, hydraulic oil, thermal oil

Description

Slag rotary cooler, tire rotary joint Product Overview

A rotary cooler tire rotary joint is a precision-engineered rotary union that connects stationary fluid supply lines to rotating equipment in tire manufacturing machinery. It allows the transfer of cooling fluids into the rotating cooler drums or tire curing presses without leakage or interruption. It maintains the necessary process temperatures for rubber vulcanization and cooling. Built to handle extreme temperatures, abrasive slag particles, and continuous operation. This rotary joint ensures uninterrupted transfer of cooling media (water, air, or thermal oil) to rotating slag coolers. With robust construction and advanced sealing technology, it minimizes downtime, reduces maintenance costs, and maximizes the efficiency of your slag processing operations.

| Specification | Inlet and return water interface | Trial pressure(Mpa) | Reference flow(T/h) |

|---|---|---|---|

| TH-XF80-50 | DN50 | 1.6 | 7 |

| TH-XF100-65 | DN65 | 1.6 | 15 |

| TH-XF125-80 | DN80 | 1.6 | 25 |

| TH-XF150-100 | DN100 | 1.6 | 45 |

| TS-XF80-50 | DN50 | 2.5 | 7 |

| TS-XF100-65 | DN65 | 2.5 | 15 |

| TS-XF125-80 | DN80 | 2.5 | 25 |

| TS-XF150-100 | DN100 | 2.5 | 45 |

| RTO-XF125-80 | DN80 | 4.0 | 30 |

| RTO-XF150-100 | DN100 | 4.0 | 50 |

| RTO-XF200-125 | DN125 | 4.0 | 85 |

| MP100-65 | DN65 | 4.0 | 16 |

| MP125-80 | DN80 | 4.0 | 30 |

| MP150-100 | DN100 | 4.0 | 50 |

| MP200-125 | DN125 | 4.0 | 85 |

Key Features of the rotary cooler tire rotary joint

Durable Sealing Technology

Equipped with advanced rotary seals, often using cartridge systems with bellows, these joints eliminate the need for springs or O-rings. It provides superior reliability and extended service life even under high-speed rotation and thermal cycling conditions.

Compact and Integrated Design

Many joints are designed to be compact or integrated directly into the shaft journal of the drum. It reduces machine width and overall footprint, which lowers manufacturing costs without compromising performance.

Versatile Media Compatibility

These rotary joints are suitable for steam, water, heat transfer oils, and coolant fluids. They support various cooling and heating requirements essential for different stages of tire production.

High-Speed and Pressure Tolerance

Designed to operate smoothly at speeds up to 150 RPM or more, withstanding pressures up to 32 bar and temperatures reaching 280°C, making them ideal for demanding industrial environments.

Low Maintenance and Easy Installation

Modular and compact construction allows for straightforward installation and minimal downtime during maintenance, maximizing production uptime.

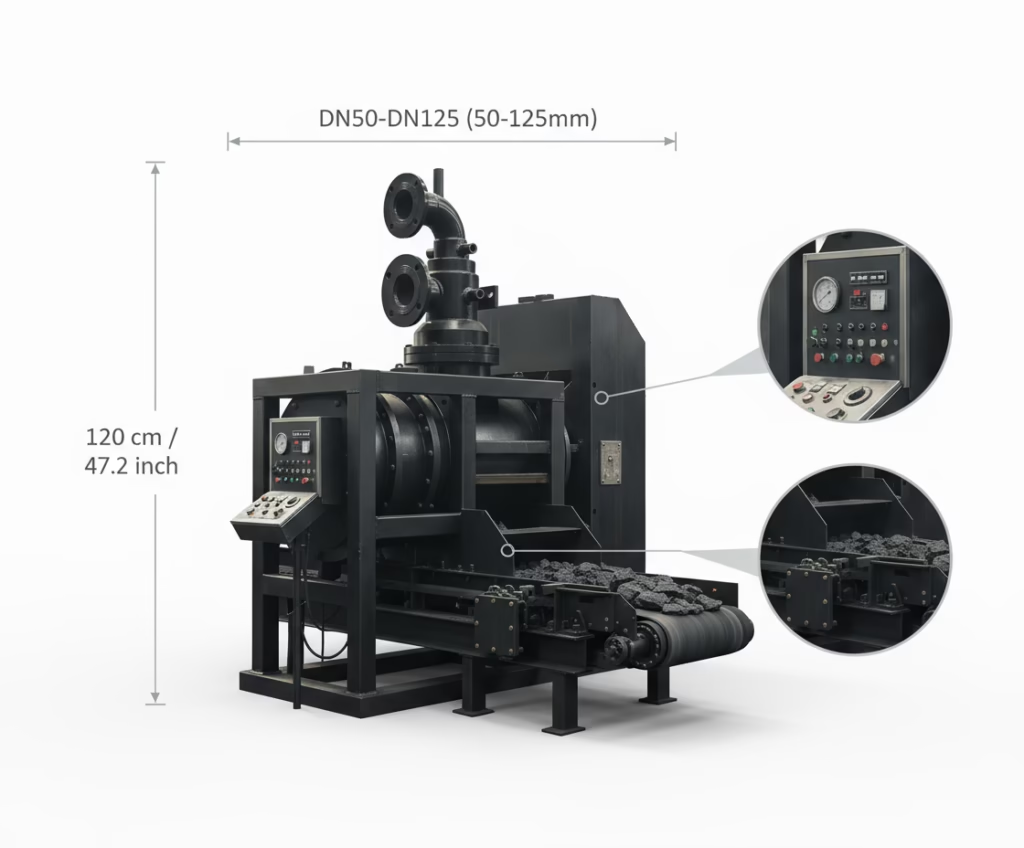

Main technical parameters

W=0.24(T1-T2)+(t2-t1), unit m’water/tSlag air cooling pipe DN200 usually connected to the entrance of the electrostatic precipitator, which can maintain the negative pressure inside the cylinder and prevent dust from overflowing and polluting. The boiler slag discharge pipe can directly inserted into the slag inlet funnel of the slag cooler, and the gap plugged with high-temperature resistant glass fiber or asbestos rope.

Product structure features of the rotary cooler tire rotary joint

The outstanding features of this series of slag coolers are: high heat transfer efficiency, wide slag discharge temperature adaptability range (40℃~150℃); the cooling water discharge pipe is outside the cylinder and the drum is safe, reliable and easy to maintain; the slag inlet pipe has a large diameter and not blocked, the slag inlet seal is perfect and its wear parts are easy to replace; variable frequency speed regulation realizes automatic tracking of boiler slag output; there are safety protections such as cooling water overtemperature alarm, water cut-off parking (and alarm), and overpressure relief.

Installation Instructions of the rotary cooler tire rotary joint

The slag cooler placed flat on the ground with a bearing capacity of not less than 600kgf/m. No anchor bolts required. Only embedded irons required at the four corners of the slag cooler base. After the slag cooler is in place, iron blocks placed on the embedded irons to prevent horizontal movement. When it is necessary to install it above the ground, two longitudinal or four transverse C30 plain concrete strip foundations can pour above the ground. When the left and right slag coolers arranged side by side, to facilitate maintenance and debugging, their drive motors should be on the outside; that is, the left slag cooler is placed on the left, and the right slag cooler is placed on the right.

Why Choose Us?

With years of experience in rotary joint manufacturing and thermal system optimization, we provide solutions that go beyond components. Our joints are engineered with over 10 years of industry expertise, combining robust materials like medium carbon steel and advanced sealing technologies to deliver unmatched performance. We offer customizable solutions tailored to your specific machine dimensions, operating speeds, and fluid media, ensuring optimal integration and efficiency. Our experts work with you to ensure perfect integration with your equipment and operational requirements.

- ISO-certified manufacturing

- Global shipping & support

- Proven track record in industrial cooling systems