CCM SS Rotary Union

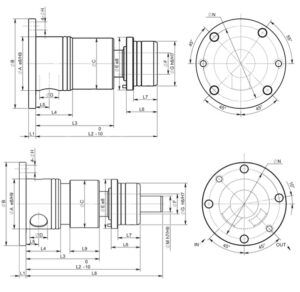

- Model: Embedded rotary joint for continuous casting machine

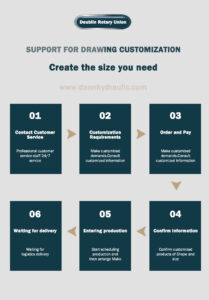

- Size: Customized Size

- Max.Speed: 60RPM

- Max. Pressure: 1.2mpa

- Max. Temperature: 120 degrees

- Applicable medium: Water, coolant

Description

Stainless Steel Continuous Casting Machine Rotary Union: Product Details

Stainless Steel Continuous Casting Machine Rotary Union: Product Details

The Stainless Steel Continuous Casting Machine Rotary Union is an essential component designed to facilitate the efficient transfer of cooling water in continuous casting processes. Engineered for durability and high performance, this rotary union ensures optimal fluid dynamics, enhancing the productivity and reliability of casting operations in the steel industry.

Robust Stainless Steel Construction: Crafted from high-grade stainless steel, this rotary union offers superior corrosion resistance and longevity, making it ideal for harsh industrial environments.

Robust Stainless Steel Construction: Crafted from high-grade stainless steel, this rotary union offers superior corrosion resistance and longevity, making it ideal for harsh industrial environments.

Advanced Sealing Technology: Utilizing innovative DuraSeal™ technology, this rotary union features a unique sealing design that enhances reliability and minimizes leakage, ensuring consistent performance even under high pressure.

Versatile Flow Options: Available in both through-flow and dual-flow configurations, the rotary union can accommodate various operational requirements, providing flexibility in application.

Self-Supported Design: The rotary union is engineered to be self-supported, simplifying installation directly onto the caster rolls while reducing space requirements.

High Performance Ratings:Max Pressure: Up to 120 PSI (8.2 bar); Max Temperature: 250°F (121°C)

Rotational Speed: Up to 5 RPM, suitable for continuous operation without compromising efficiency.

The Stainless Steel Continuous Casting Machine Rotary Union is specifically designed for applications in:

Steel Manufacturing: Essential for cooling rolls during the solidification of molten steel.

Metallurgy: Used in processes requiring precise temperature control through effective cooling.

Industrial Machinery: Suitable for any machinery that requires reliable fluid transfer under challenging conditions.

Benefits of Choosing Our Rotary Union

Enhanced Efficiency: By ensuring a steady flow of cooling water, this rotary union helps maintain optimal temperatures during the casting process, improving product quality and reducing defects.

Reduced Maintenance Costs: The durable construction and advanced sealing technology minimize wear and tear, leading to lower maintenance requirements and extended service life.

Easy Installation and Repair: Designed for straightforward installation on caster rolls, the rotary union can be easily serviced in the field, minimizing downtime during maintenance.

Why Choose Us?

Why Choose Us?

Our Stainless Steel Continuous Casting Machine Rotary Union stands out due to its combination of quality materials, innovative design, and proven performance. With years of experience in the industry, we are committed to providing solutions that enhance operational efficiency and reliability.