T Series Rotoflux Rotary Unions for Multi-Fluid Transfer

Original price was: $80.00.$60.00Current price is: $60.00.

- Max Pressure: 10 bar (145 PSI)

- Max Temperature: 120 °C (248 °F)

- Max Rotation Speed: 3,500 RPM

- Connection Type: G 1/4” BSPP

- Materials: Stainless Steel / Brass

Description

Product Overview of T Series Rotoflux Rotary Unions

The Rotoflux T Series Rotary Unions offer a robust and durable solution for single-flow media transfer under rotation. Its compact design, combined with advanced sealing technology, supports moderate to high rotational speeds and pressures while ensuring minimal leakage and wear. The T Series features brass or aluminum bodies with stainless steel rotors, providing longevity and corrosion resistance in demanding industrial environments.

The T Series Rotoflux Rotary Unions a precision-engineered, single-passage rotary joints designed to enable reliable fluid and gas transfer between stationary and rotating components in industrial machinery. Manufacturers optimize it for pneumatic air, vacuum, hydraulic oil, and various fluid applications, making it an essential component in automation, machine tools, and industrial process systems. It represents the next generation of rotary coupling technology, combining unmatched versatility, reliability, and performance. Whether your application demands high-speed air transfer for pneumatic tools, precise coolant delivery for milling spindles, or multi-media distribution for advanced robotic end-effectors, the T Series delivers leak-free operation across a broad spectrum of pressures, temperatures, and media.

Key Features of T Series Rotoflux Rotary Unions

✅ Ultra-High Speed & Dry-Running Capability

Operates at 10,000 RPM under dry conditions, minimizing wear through tungsten carbide seals and dynamic balancing to reduce vibration.

Ideal for high-speed CNC spindles and robotic arms requiring precision coolant or air supply.

✅ Extreme Pressure & Temperature Resistance

Max Pressure: 400 BAR (5800 PSI) for hydraulic systems, ensuring reliable performance in presses and injection molding.

Temperature Range: -20°C to 120°C (-4°F to 248°F), adaptable to harsh industrial environments.

✅ Multi-Media Compatibility

Transfers hydraulic oil, coolant, compressed air, steam, and inert gases safely.

Customizable materials: Stainless steel, aluminum alloy, or brass for corrosion resistance in chemical, pharmaceutical, and food-grade applications.

✅ Compact & Universal Design

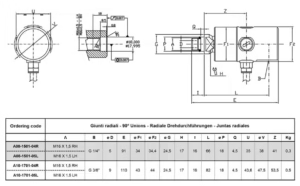

Threaded Ports (M16×1.5L): Easy integration with standard industrial equipment, reducing retrofitting time.

Lightweight (1.2kg) and space-saving, ideal for confined machinery layouts.

✅ Low-Maintenance & Longevity

Spring-loaded sealing mechanism prevents turbulence-induced leaks and extends service life.

Modular design allows rapid seal replacement, minimizing downtime and maintenance costs.

Closed seal, automatic line, or similar application

Closed seal, automatic line, or similar application

Full flow design, no debris and burr clogging

Bearing support and threaded rotor, easy to install

Deep groove radial ball bearing, smooth operation

Ball bearings protected by a labyrinth seal and with large leakage

| Parameter | Specification |

|---|---|

| Media | Air, Vacuum, Hydraulic Oil |

| Max Pressure (Air) | 10 bar (145 PSI) |

| Max Pressure (Oil) | 20 bar (290 PSI), 50 bar (725 PSI) D version |

| Max Vacuum | 7 kPa (2” Hg) |

| Max Temperature | 95°C (203°F) |

| Max RPM | Up to 3,500 RPM (varies by size) |

| Body Material | Brass or Aluminum |

| Rotor Material | Stainless Steel |

| Seal Material | Carbon Graphite (N), Tungsten Carbide (D) |

| Seal Type | Balanced and Micro-Lapped |

Applications of T Series Rotoflux Rotary Unions

The T Series Rotoflux Rotary Union excels in various industrial sectors due to its versatility and robust design:

Pneumatic Systems

Enables compressed air transfer in rotary pneumatic actuators, rotary indexing tables, and rotating drums, ensuring continuous air supply without hose twisting or leakage.

Vacuum Applications

Facilitates vacuum transfer in rotating vacuum chambers or suction devices, maintaining consistent vacuum pressure during rotation.

Hydraulic Oil Circuits

Supports hydraulic fluid flow in rotating hydraulic motors or swivels, critical for mobile machinery and industrial automation.

Machine Tool Cooling

Delivers coolant fluids through rotating spindles, preventing overheating and enhancing machining precision.

Steam and Diathermic Oil Transfer

Suitable for intermittent steam and heat transfer fluids in rotating heat exchangers or processing equipment.

Abrasive and Dirty Fluid Handling

The D version seals allow operation with abrasive liquids, expanding usability in harsh environments such as mining, chemical processing, and wastewater treatment.

Why Choose the T Series Rotoflux Rotary Unions?

Versatility & Customization

Scale from single-channel to 12-channel units—mix and match air, oil, coolant, and vapor within the same compact housing.

Unmatched Reliability

Industry-leading seal life, minimal maintenance intervals, and robust construction deliver years of uninterrupted operation.

Performance-Driven Design

High-speed capabilities, hydrodynamic sealing, and low-inertia construction translate to smoother machine operation and higher throughput.

Global Certifications & Support

ISO 9001 quality assurance, CE and ATEX approvals, and worldwide Rotoflux service centers ensure compliance and rapid technical assistance.

Enhanced Uptime & Lower Costs

Quick-change seal cartridges and modular port plates reduce downtime by up to 80% compared to competitors, maximizing ROI on your rotating equipment.

Benefits and Advantages of T Series Rotoflux Rotary Unions

Robust Sealing Technology

We equip the T Series with advanced sealing mechanisms, including balanced and micro-lapped seals. These seals specifically handle high pressures and prevent leaks, which is crucial when working with water and steam under significant pressure.

High-Pressure Tolerance

The T Series ROTOFLUX Rotary Union can withstand pressures up to 50 bar (750 PSI), making it suitable for both water and steam applications where pressure management is critical. This high-pressure capability ensures that the rotary union can maintain integrity and performance even under demanding conditions.

Temperature Resistance

This rotary union is designed to operate effectively at temperatures up to 200 °C (392°F) for steam applications. The ability to handle high temperatures is essential for steam transfer, as it allows the rotary union to function safely without compromising performance.

Material Composition

The T Series is constructed from durable materials such as stainless steel and brass, which are resistant to corrosion and wear. The use of high-quality materials ensures longevity and reliability in environments where water and steam are present, reducing the risk of failure over time.

Versatile Fluid Compatibility

The T Series ROTOFLUX is compatible with a variety of fluids, including water, steam, and hot oil. This versatility makes it an excellent choice for applications requiring fluid transfer in diverse industrial settings, from manufacturing to energy production.

Compact Design

Its compact design allows for easy installation in tight spaces while maintaining functionality. This feature is particularly beneficial in environments where space constraints are a concern, such as within machinery or equipment setups.

Ease of Maintenance

The design of the T Series facilitates straightforward maintenance procedures. Regular checks can be performed easily, ensuring that the rotary union continues to operate efficiently over time without extensive downtime.

FAQ of T Series Rotoflux Rotary Unions

What is the T Series ROTOFLUX Rotary Union?

The T Series ROTOFLUX Rotary Union is a specialized component designed for efficient fluid transfer in rotating applications. It is particularly suitable for air, vacuum, and hydraulic oil applications, providing reliable performance in various industrial settings.

What industries commonly use the T Series ROTOFLUX?

Industries that benefit from the T Series include: Machine Tool Manufacturing, Automotive Production, Food Processing, Energy Generation, and Textile Manufacturing.

How does the design of the T Series contribute to its durability?

The T Series ROTOFLUX is constructed from high-quality materials such as brass or aluminum bodies and stainless steel rotors. This robust construction ensures resistance to wear and corrosion, allowing it to perform reliably in harsh environments.

Can the T Series ROTOFLUX handle dry running conditions?

Yes, certain models of the T Series are designed to handle dry running conditions effectively. This capability allows for operation without fluid under specific circumstances, making it versatile for various applications.

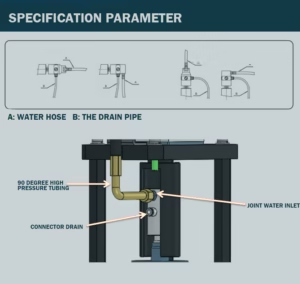

What are the installation requirements for the T Series ROTOFLUX?

Installation requirements include ensuring that the rotary union is mounted securely without stress on connections, using flexible hoses to accommodate movement, and verifying that it operates within specified pressure and temperature limits to avoid damage.

What maintenance is required for the T Series ROTOFLUX?

Regular maintenance involves checking seals for wear, ensuring connections are secure, lubricating as needed, and inspecting for leaks. Routine checks help maintain optimal performance and extend the lifespan of the rotary union.