Rotary joint working principle

Introduction

In the intricate world of industrial machinery and fluid transfer systems, rotary joints play a crucial yet often underappreciated role. I’ve noticed that the query “Rotary joint working principle” frequently pops up in search trends, indicating a high demand for in-depth knowledge. In this blog, we’ll journey to understand the inner workings of rotary joints, exploring their components, how they function, and their diverse applications. By the end, you’ll have a solid grasp of what makes these devices tick and why they are essential in numerous industries.

What is a Rotary Joint?

Before delving into the working principle, it’s essential to define what a rotary joint is. A rotary joint, also known as a swivel joint or swivel union, is a mechanical device that allows the transfer of fluids—such as water, steam, hydraulic oil, or chemicals—from a stationary source to a rotating component in a machine or system. Unlike fixed connections, rotary joints enable continuous rotation while maintaining a leak-proof seal, ensuring the efficient and safe transfer of fluids under various operating conditions.

Rotary joints come in various shapes, sizes, and configurations, each designed to meet specific application requirements. They can range from simple, single-passage joints used in basic conveyor systems to complex, multi-passage joints capable of handling multiple fluids simultaneously in high-speed industrial processes.

Key Components of a Rotary Joint

To understand how a rotary joint works, we first need to familiarize ourselves with its key components. Each part plays a vital role in enabling the joint to rotate smoothly and transfer fluids effectively.

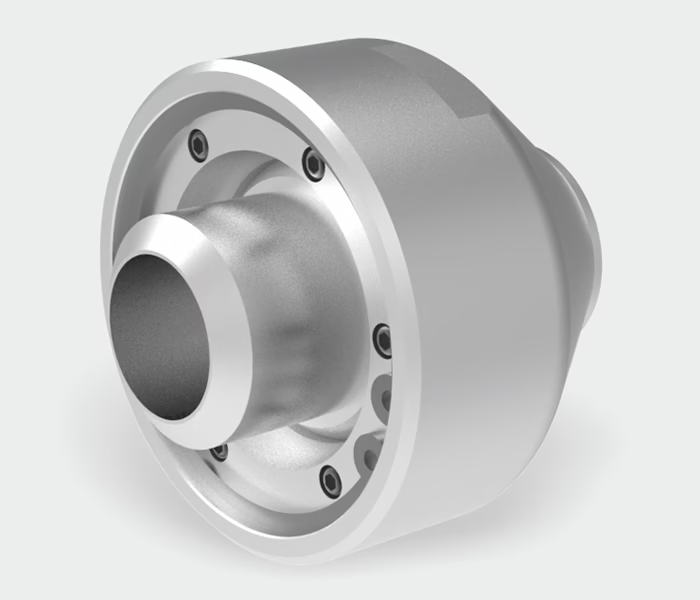

The Housing

The housing serves as the outer shell of the rotary joint, providing structural support and containing all the internal components. Manufacturers typically construct it from durable materials such as stainless steel, carbon steel, or high-strength alloys to withstand the rigors of industrial environments. The housing also features inlet and outlet ports, which connect to the stationary fluid supply and the rotating equipment, respectively. These ports ensure a secure and leak-free connection, preventing fluid loss and maintaining system integrity.

The Rotating Shaft

At the heart of the rotary joint is the rotating shaft. This component connects to the rotating machinery, such as a drum, reel, or spindle, and rotates along with it. The shaft must be robust enough to handle the mechanical loads imposed by the rotating equipment while allowing fluids to pass through its internal passages. To achieve this, engineers often machine the shaft from high-quality materials with excellent strength and wear-resistant properties. Additionally, they may apply surface treatments, such as hard chrome plating or nitriding, to enhance their durability and reduce friction.

Sealing Elements

Sealing elements are crucial for maintaining a leak-proof connection between the stationary housing and the rotating shaft. Rotary joints commonly use different types of seals, including mechanical seals, lip seals, and O – O-rings. Mechanical seals are the most prevalent in industrial applications due to their ability to handle high pressures, temperatures, and speeds. They consist of two mating surfaces, one fixed to the housing and the other attached to the shaft, which create a tight seal when pressed together. Lip seals and O-rings, on the other hand, are simpler and more cost-effective options, often used in lower-pressure and lower-speed applications.

Bearings

Bearings support the rotating shaft, allowing it to spin smoothly with minimal friction. Depending on the application requirements, rotary joints may use various types of bearings, such as ball bearings, roller bearings, or plain bearings. Ball bearings are popular due to their high load-carrying capacity and low friction characteristics, making them suitable for high-speed applications. Roller bearings can handle heavier loads and are often used in applications where radial and axial loads are significant. Plain bearings, also known as sleeve bearings, are simpler and more cost-effective, but they may require more frequent lubrication.

Fluid Passages

The internal fluid passages within the rotary joint enable the transfer of fluids from the stationary source to the rotating equipment. These passages can be single or multi-channel, depending on the number of fluids the joint needs to handle. In multi – passage rotary joints, each fluid has its dedicated passage to prevent cross – contamination. Engineers design the fluid passages to ensure smooth fluid flow, minimizing pressure drops and turbulence.

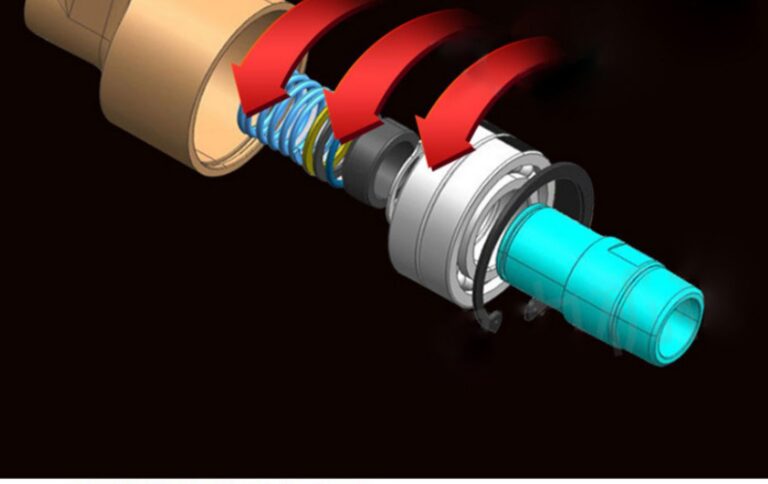

How Does a Rotary Joint Work?

Now that we understand the key components of a rotary joint, let’s explore how they work together to facilitate fluid transfer during rotation.

Assembly and Initial Setup

When assembling a rotary joint, technicians carefully install each component, ensuring proper alignment and tight connections. They mount the housing to the stationary part of the system, such as a pipe or frame, and attach the rotating shaft to the rotating equipment. They then install the sealing elements and bearings, making sure they are in the correct position and properly lubricated. Finally, they connect the inlet and outlet ports to the fluid supply and the rotating equipment, respectively.

Fluid Inlet and Pressure Build-up

Once the rotary joint is in place and the system is operational, fluid enters the joint through the inlet port. As the fluid flows into the housing, it creates pressure within the internal fluid passages. This pressure forces the fluid to move towards the rotating shaft and out through the outlet port, which connects to the rotating equipment.

Rotation and Sealing

As the rotating equipment starts to spin, the shaft rotates along with it. The sealing elements play a critical role during rotation, maintaining a tight seal between the stationary housing and the rotating shaft. In the case of mechanical seals, the two mating surfaces rub against each other as the shaft rotates. A thin film of fluid forms between the surfaces, acting as a lubricant and preventing direct contact, which could lead to wear and leakage. Lip seals and O-rings also maintain a seal by creating a physical barrier between the housing and the shaft, preventing fluid from escaping.

Fluid Transfer and Outlet

As the fluid moves through the internal passages of the rotary joint, it reaches the outlet port and is transferred to the rotating equipment. The design of the fluid passages and the pressure within the system ensure a continuous and efficient flow of fluid, even as the shaft rotates at high speeds. Once the fluid reaches the rotating equipment, it performs its intended function, such as cooling, lubricating, or powering the machinery.

Maintenance and Longevity

To ensure the long-term performance of a rotary joint, regular maintenance is essential. This includes checking and replacing seals when they wear out, lubricating the bearings as per the manufacturer’s recommendations, and inspecting the housing and shaft for signs of damage or corrosion. By following a proper maintenance schedule, you can extend the lifespan of the rotary joint and prevent costly breakdowns.

Types of Rotary Joints and Their Applications

Not all rotary joints are created equal. The right choice depends on your application’s demands:

1. Single-Passage vs. Multi-Passage Joints

Single-passage: Transfers one media type (e.g., water for cooling).

Multi-passage: Handles multiple fluids simultaneously (e.g., oil and air in hydraulic systems).

Use case: A plastic injection molding machine uses a dual-passage joint to circulate both cooling water and hydraulic fluid.

2. High-Speed vs. High-Pressure Joints

High-speed joints: Use lightweight materials and aerodynamic seals for applications like centrifuges.

High-pressure joints: Feature reinforced housings for hydraulic presses or oil drilling equipment.

3. Specialized Designs

Steam joints: Withstand temperatures up to 350°C (662°F) in paper mills.

Sanitary joints: FDA-compliant for food/pharmaceutical processing.

Optimizing Rotary Joint Performance

Even the best-designed joints require proper maintenance and setup. Here’s how to maximize their lifespan:

1. Installation Best Practices

Align shafts precisely: Misalignment causes premature seal wear.

Use torque wrenches: Over-tightening bolts can distort the housing.

Install support brackets: Prevent vibration-induced stress on pipes.

2. Maintenance Checklist

Daily: Inspect for leaks and unusual noise.

Weekly: Check bearing lubrication levels.

Monthly: Measure shaft runout (shouldn’t exceed 0.1mm).

Pro tip: Replace seals every 6–12 months, depending on operating conditions.

3. Common Troubleshooting Solutions

Fluid leakage often stems from worn seals or component misalignment. Prolonged use can degrade seals, while installation errors may cause misalignment. To resolve this, replace the seals and recalibrate the equipment’s position.

Overheating is frequently linked to inadequate lubrication. Insufficient or poor-quality lubricant can increase bearing friction. Address this by thoroughly cleaning the bearings and applying the recommended grease.

A noticeable reduction in fluid flow typically indicates blocked ports or internal scaling. Sediment buildup can obstruct media passage, requiring thorough flushing with appropriate cleaning agents.

The Future of Rotary Joint Technology

As industries evolve, so do rotary joints. Emerging trends include:

1. Smart Rotary Joints

Sensors embedded in joints now monitor:

Temperature

Vibration

Fluid pressure

This data enables predictive maintenance, reducing downtime by up to 40%.

2. Eco-Friendly Designs

Biodegradable seal materials and closed-loop fluid systems minimize environmental impact.

3. 3D-Printed Components

Custom joints for niche applications (e.g., wind turbines) can now be prototyped and manufactured faster than ever.

FAQs

Q1: Can rotary joints handle abrasive fluids?

A: Specialized designs with tungsten carbide seals can manage slurries or corrosive chemicals, but regular inspections are critical.

Q2: What’s the average lifespan of a rotary joint?

A: 5–15 years, depending on maintenance and operating conditions.

Q3: How do I choose between mechanical and magnetic seals?

A: Mechanical seals offer durability in high-pressure settings, while magnetic seals prevent friction entirely (ideal for sterile environments).

Choosing the Right Rotary Joint

Selecting the appropriate rotary joint for a specific application is crucial to ensure reliable performance and prevent costly failures. Here are some factors to consider when choosing a rotary joint:

Fluid Type

The type of fluid the rotary joint needs to handle is one of the most critical factors. Different fluids have different properties, such as viscosity, temperature, and chemical compatibility. For example, if you’re transferring steam, you’ll need a rotary joint that can withstand high temperatures and pressures. If you’re handling corrosive chemicals, you’ll need a joint made from materials that are resistant to corrosion.

Operating Pressure and Temperature

The operating pressure and temperature of the system also play a significant role in rotary joint selection. Make sure the rotary joint you choose can handle the maximum pressure and temperature that the system will encounter during operation. Exceeding the rated pressure or temperature can lead to seal failure, leakage, and damage to the joint.

Rotation Speed

The rotation speed of the equipment is another important consideration. High-speed applications require rotary joints with bearings and seals that can withstand the increased centrifugal forces and friction. Some rotary joints are specifically designed for high – speed operation, featuring advanced sealing technologies and precision – engineered bearings.

Number of Passages

If your application requires the transfer of multiple fluids, you’ll need a multi-passage rotary joint. Consider the number of fluids, their flow rates, and the required separation between the passages to prevent cross-contamination.

Mounting and Installation

The mounting and installation requirements of the rotary joint should also match your system. Ensure that the joint’s size, shape, and mounting configuration are compatible with the available space and the existing equipment.

Conclusion

In conclusion, rotary joints are essential components in a wide range of industrial applications, enabling the seamless transfer of fluids during rotation. By understanding their working principle, key components, and applications, you can make informed decisions when selecting, installing, and maintaining rotary joints in your systems. Whether you’re in the manufacturing, printing, oil and gas, food and beverage, or power generation industry, rotary joints are likely to play a crucial role in your operations.

I hope this comprehensive guide not only satisfies your search for knowledge on rotary joint working principles but also helps you optimize your content related to this topic, attracting more relevant traffic to your website. If you have any further questions or need more in-depth information on specific aspects of rotary joints, feel free to leave a comment below.