The Key Role of Rotary Unions in Power Generation and Their Application Value

In modern power industry systems, the efficient operation of each process relies heavily on precision mechanical components. Among these components, the rotary union, an essential device enabling the stable transmission of energy and fluids between rotating bodies and fixed structures, has long become an indispensable “bridge” in the power generation sector. With exceptional sealing performance, resistance to harsh environments, and high transmission efficiency, rotary unions solve critical issues such as fluid leakage, signal interruptions, and energy losses during the dynamic operation of power generation equipment. They play an irreplaceable role in various fields such as wind power, hydroelectric power, nuclear power, and thermal power generation, laying a solid foundation for the stable output of power systems and improving energy utilization efficiency.

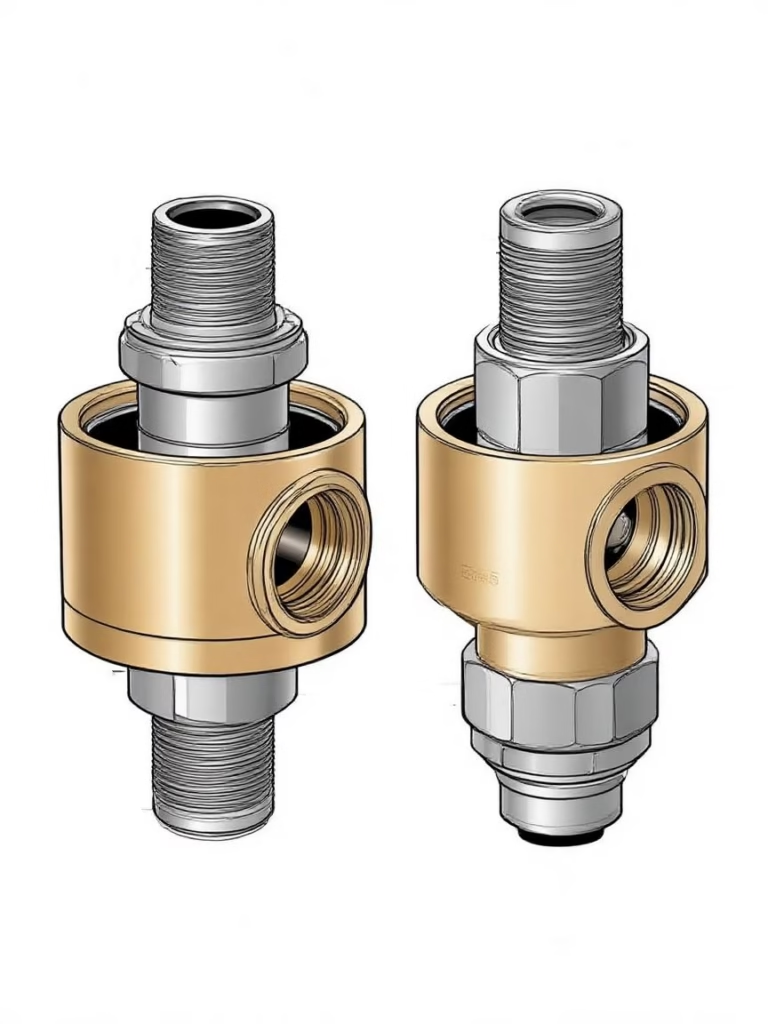

Rotary Unions: The “Core Bridge” for Dynamic Transmission in Power Equipment

The core value of a rotary union lies in its unique structural design. Through the coordinated action of key components such as dynamic-static sealing pairs, bearing support systems, and compensation mechanisms, it enables continuous, leak-free transmission of fluids such as hydraulic oil, cooling water, steam, and lubricating oil, as well as electrical signals and energy under extreme conditions like high-speed rotation, high temperature and pressure, and strong corrosion. In power generation equipment, whether it is the real-time pitch control of wind turbine blades, cooling and lubrication of hydro turbine shafts, or steam driving of steam turbines, rotary unions are essential to maintaining stable transmission performance under dynamic conditions.

Industry data shows that in mature power generation equipment, the reliability of the rotary union directly affects the failure rate of the entire machine. High-quality rotary unions can reduce downtime for maintenance by more than 30%, significantly enhancing the continuous operational time of power generation systems. This makes rotary unions an important indicator of the performance quality of power generation equipment.

Application in Wind Power Generation: Ensuring Efficient Energy Capture and Safe Operation of Wind Turbines

With the rapid development of the renewable energy industry, wind power generation has become a key force in the global energy transition. Rotary unions directly determine the efficiency of wind energy capture and the operational safety of wind turbines. In large onshore and offshore wind turbine systems, multi-path hydraulic rotary unions serve as key components connecting the fixed part of the tower and the rotating part of the nacelle, functioning as a “hub for nerves and blood vessels.” These unions not only transmit hydraulic system power but also ensure stable electrical signal transmission.

In particular, the pitch control of wind turbine blades is a core step in maximizing wind energy utilization. When wind speed changes, the control system uses hydraulic rotary unions to precisely deliver pressure oil to the hydraulic actuator at the base of the blades to adjust their angle.

When wind speed is low, the blades are adjusted to a maximum angle to capture more wind energy, while at high wind speeds, the blades are quickly returned to a neutral position to avoid overloading. For example, in a 1.5 MW wind turbine, each blade requires an independent hydraulic drive system. Multi-path rotary unions can simultaneously transmit 3-5 hydraulic lines while maintaining sealing performance during the nacelle’s 360-degree continuous rotation, with leakage controlled to below 0.1 mL/min. This ensures precise and timely pitch control. Additionally, rotary unions provide power and data transmission channels for the turbine’s wind speed sensors and vibration monitoring equipment, enabling the control system to monitor turbine status in real-time.

In offshore wind farms, the challenges for rotary unions are even more severe due to the high salt fog environment that accelerates corrosion of metal parts and strong gusts that may increase equipment vibration. For this reason, offshore-specific rotary unions are typically made from corrosion-resistant Hastelloy materials for sealing rings, combined with double-row angular contact bearings to enhance anti-vibration performance. The addition of rubber dust covers and drainage structures on the housing significantly extends the lifespan of these rotary unions. Practical results show that specially designed rotary unions in offshore wind farms can achieve an average non-failure operating time of over 8,000 hours, far exceeding the 5,000-hour standard of ordinary rotary unions, ensuring the reliable operation of offshore wind farms.

Application in Hydropower Station Equipment: Ensuring Stable Operation of Water Turbines and Generators

As a traditional form of clean energy generation, hydropower stations rely on the long-term stable operation of core equipment like water turbines and generators, which is supported by the critical role of rotary unions in cooling and lubrication systems. During operation, significant frictional heat is generated between the main shaft and bearings of a water turbine. Without timely cooling, this can lead to bearing overheating, damage, or even shaft deformation. Additionally, the stator and rotor of the generator produce high temperatures due to electromagnetic induction during high-speed rotation. If the temperature exceeds design limits, it can severely affect the insulation performance of the motor and shorten its lifespan. Here, cooling water rotary unions act as the “key guardian” to solve this problem.

In large mixed-flow water turbines, rotary unions are installed at the shaft end. One end of the rotary joint connects to the fixed cooling water pipeline. The opposite end rotates in sync with the shaft. Cooling water is delivered evenly to the bearing and shaft contact surfaces. Heated water is efficiently directed out of the system. For example, at the Three Gorges hydropower station, the main shaft diameter exceeds 4 meters, and the rotation speed is 75 rpm. The cooling water rotary union uses a multi-ring sealing structure to withstand working pressures of 0.8 MPa and water temperatures up to 50°C, transporting more than 200 cubic meters of cooling water per hour, ensuring the shaft neck temperature remains below 40°C. Additionally, in the stator cooling system of the hydro-generator, rotary unions also transport cooling media to the rotating rotor windings, removing heat generated by electromagnetic losses.

Besides cooling, rotary unions also play an important role in lubrication systems at hydropower stations. Guide bearings and thrust bearings of water turbines require a continuous supply of lubricating oil to reduce friction, and rotary unions can deliver lubricating oil from fixed oil tanks to rotating bearing housings while recycling used oil, forming a closed-loop lubrication system. Data from a large hydropower station’s operation and maintenance system show that using high-quality rotary unions can reduce bearing wear by 40% and extend the lubricating oil replacement cycle to 18 months, not only reducing operational costs but also minimizing waste oil pollution to the environment.

Application in Thermal and Nuclear Power Generation: Supporting Energy Conversion and Auxiliary System Operation

Thermal and nuclear power generation, as the mainstay of traditional power supply, relies on rotary unions in crucial roles, whether directly in energy transmission or in supporting system operations. In thermal power plants, steam turbines are the core equipment that converts thermal energy into mechanical energy. Their operation depends on high-temperature, high-pressure steam. The steam rotary union, as a key component connecting the steam pipe and turbine shaft, must deliver steam without leakage under extreme conditions (typically exceeding 400°C and up to 10 MPa). High-temperature, high-pressure steam enters the turbine through the steam rotary union. The steam drives the rotor to rotate. The rotating rotor generates electricity efficiently.

To withstand such extreme conditions, steam rotary unions often use high-temperature-resistant graphite sealing rings and high-strength alloy housings, along with cooling jackets to reduce the temperature of the sealing components, ensuring that no sealing failure occurs during long-term operation. For a 300 MW thermal power unit, high-quality steam rotary unions can control steam leakage to below 0.5%, reducing steam loss by over 1,000 tons per year and significantly improving the thermal efficiency of the unit.

In nuclear power plants, rotary unions do not directly participate in the nuclear reaction. They play an essential role in auxiliary systems such as steam generators, main coolant pumps, and circulating water pumps. The steam generator transfers heat from reactor coolant to secondary-side water. This process produces steam that drives the turbine. The main coolant pump circulates coolant through the reactor. The pump’s main shaft sealing system relies on rotary unions. Rotary unions ensure leak-free coolant transmission under high pressure of approximately 15 MPa. They also operate reliably in strong radiation environments. Nuclear plant rotary unions typically use double-seal structures. Real-time leakage monitoring systems immediately trigger alarms if leaks occur. Backup seals are activated automatically to maintain safety. These measures ensure the safe and reliable operation of nuclear auxiliary systems.

Comprehensive Benefits: From Efficiency Enhancement to Safety and Environmental Protection

Rotary unions in the power generation industry support the efficient operation of various power generation equipment. They enhance operational efficiency while ensuring safety. They also contribute to environmental protection and sustainability. From an efficiency perspective, the high transmission performance of rotary unions directly reduces energy loss. In wind power, precise pitch control increases wind turbine energy utilization by 5%–8%. In thermal power, low-leakage steam rotary unions improve unit thermal efficiency by 1%–2%. Hydroelectric power, stable cooling, and lubrication systems maintain water turbine generation efficiency above 90%. Based on China’s annual power generation of 8 trillion kWh, rotary unions significantly contribute to overall efficiency. Their efficiency contribution could generate several billion kWh annually. This is equivalent to constructing several large-scale power plants.

In terms of safety, the high reliability of rotary unions significantly reduces the risk of power generation equipment failures. In nuclear power plants, double seals and leak detection systems form a crucial line of defense for nuclear safety. As offshore wind farms, anti-corrosion and anti-vibration designs reduce maintenance downtime. In hydro plants, stable cooling systems prevent equipment damage due to bearing overheating. Statistical data shows that power generation equipment with high-quality rotary unions experiences significantly fewer failures. Major failure rates can be reduced by over 25%. This reduction provides strong support for the safe operation of power systems. It also ensures stable and reliable performance across the equipment.

From an environmental protection standpoint, the excellent sealing performance of rotary unions minimizes environmental pollution from leaked media. In thermal power, reduced steam leakage helps lower greenhouse gas emissions. In hydroelectric plants, minimizing lubricating oil leakage prevents water pollution. Nuclear plants control cooling agent leakage and protect against radiation hazards. The long service life of rotary unions reduces the frequency of component replacements. Fewer replacements lower waste generation. This contributes to a greener, low-carbon development approach.

Conclusion: Supporting the High-Quality Development of Modern Power Industries

As the power industry continues to evolve towards intelligence, sustainability, and efficiency, the technical demands for rotary unions will continue to rise. Future developments will focus on achieving higher sealing performance, stronger resistance to harsh environments, and smarter condition monitoring functions. Intelligent rotary unions with integrated sensors enable real-time monitoring of temperature, pressure, and leakage. Data is transmitted to maintenance platforms through IoT technologies. This enables predictive maintenance and reduces unexpected downtime. Rotary unions made from new composite materials improve temperature, pressure, and corrosion resistance. These advanced materials allow operation under more extreme power generation conditions.

Rotary unions are key technical accessories in the power generation industry. They support both traditional and renewable energy sectors. They operate reliably in land-based facilities and offshore platforms. Their unique functionality and technological advantages ensure stable power production. Rotary unions act as “physical bridges” connecting moving and stationary equipment parts. They also serve as “technological cornerstones” driving progress in the power industry. They help ensure energy security and support green development initiatives. Continuous technological innovation will further enhance their role in modern power industry development. Rotary unions contribute significantly to the global energy transition. They also support achieving national and global “dual-carbon” goals.