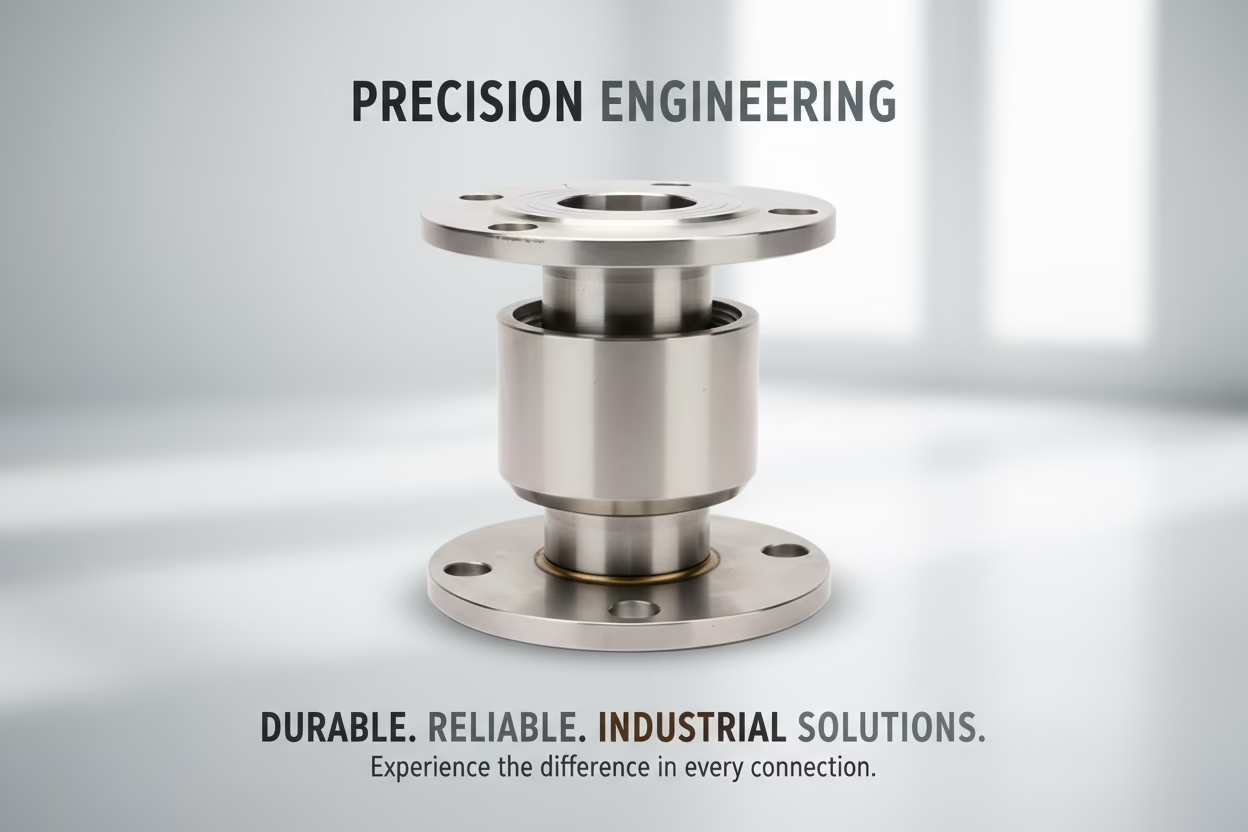

The Dn Stainless Steel Rotary Joint – A Lifesaver For Spraying De-Icing Agents On Water Trucks

As the grip of winter tightens, icy roads become a critical threat to public safety. Water trucks — often called “brine sprayers” — take the front line each winter, actively defending roads by spraying de-icing agents. However, despite their vital role, they continue to face persistent technical challenges during this critical operation. The corrosive mix of de-icing agents (saline brine, magnesium chloride, etc.) and water is notoriously difficult to manage. Unstable flow, frequent pipe clogging, and uneven spray patterns are common problems that directly sabotage efficiency and effectiveness. To conquer these costly pain points, the Dn Stainless Steel Rotary Joint has emerged as an indispensable component. This piece of precision engineering is not just an accessory; it is the core solution that ensures reliability in the demanding world of winter road maintenance.

This article provides an in-depth analysis of the problems with traditional spraying systems and details how the innovative technology of the Dn Stainless Steel Rotary Joint provides the ultimate answer.

Confronting the Core Problem: The Failures of Traditional De-Icing Systems

Confronting the Core Problem: The Failures of Traditional De-Icing Systems

Anyone in the fleet maintenance or municipal works industry is all too familiar with the shortcomings of conventional spraying equipment. The root of the problem lies in the physicochemical properties of the de-icing agents themselves.

Corrosion and Crystallization

De-icing fluids are, by nature, highly corrosive. These saline-based solutions attack standard metal components like iron, copper, and even low-grade steel. Furthermore, as temperatures fluctuate, these solutions are prone to crystallization. Small salt crystals begin to form, acting like microscopic sandpaper within the fluid transfer system.

Clogging and Blockages

These crystals and precipitates quickly accumulate in the system’s most vulnerable points: narrow pipes, bends, and, most frequently, the rotating connection that feeds the spray boom. This leads to clogged pipes and encrusted spray nozzles.

Uneven Application

A partially clogged system cannot maintain consistent pressure or flow. This imbalance creates an uneven spray pattern, often leaving visible “stripes” on the road — with some areas receiving too much de-icing agent, while others are completely missed.

These failures create a cascade of negative consequences:

- Increased Maintenance Costs: Trucks are forced into downtime for flushing and repair. Corroded components must be replaced, and clogged nozzles require hours of manual cleaning.

- Wasted Materials: Uneven spraying means more de-icing agent is used than necessary to achieve the desired effect, driving up material costs.

- Ineffective De-Icing: Missed spots on the road remain hazardous, defeating the entire purpose of the operation and increasing public risk.

- Environmental Damage: Over-spraying can harm roadside vegetation and lead to excessive chemical runoff into groundwater.

The Dn Stainless Steel Rotary Joint: A Perfect Engineered Solution

The DN Stainless Steel Rotary Joint was designed from the ground up to solve these specific challenges. Its innovative mechanical structure and precision-engineered design directly counteract the issues of corrosion, clogging, and instability.

At its core, a rotary joint (or rotary union) is a device that allows the transfer of fluid from a stationary pipe to a rotating piece of equipment. In this case, it connects the truck’s tank to the adjustable spray boom. The DN series leverages unique rotating seal technology to ensure the de-icing mixture remains in a stable, uniform flow state throughout transmission.

The true innovation lies in its internal flow path. This component does far more than act as a simple pipe — it features a precision-machined channel that actively optimizes fluid dynamics for smoother, more efficient flow. This specialized design effectively reduces flow resistance and minimizes turbulence, preventing solid precipitates from settling and accumulating. By eliminating the internal “dead zones” where crystals can build up, the Dn Stainless Steel Rotary Joint fundamentally prevents the root cause of pipe blockages.

The DN stainless steel rotary joint addresses these challenges through an innovative mechanical structure and precision design. Employing a unique rotary-seal mechanism, it ensures that the mixed de-icing fluid flows stably and evenly throughout the delivery system. Inside the joint, the precision-machined flow channels reduce fluid resistance, minimise sediment accumulation, and fundamentally eliminate pipe blockages.

Core Technical Advantages

Excellent Sealing Performance

The DN rotary joint uses high-quality sealing materials and advanced seal structures. It can maintain outstanding sealing under high-pressure and low-temperature conditions typical of winter spraying operations. Specially developed seal rings offer corrosion resistance, wear resistance, and excellent anti-aging performance, ensuring that leakage does not occur throughout the service life.

Flexible Adjustable Orientation

This rotary joint supports multi-angle, multi-directional flexible adjustment. Operators can precisely set spray angle and coverage range according to actual work-site needs. This design allows the de-icing agent to spread more precisely across the road surface, ensuring faster melting, improving overall efficiency, and reducing material waste.

Wide Adaptability

The DN rotary joint utilises a standardised interface design, with strong compatibility and interchangeability. Whether the water truck is a compact municipal unit or a large highway snow-removal vehicle, operators can easily find a compatible model that fits their system requirements. This adaptability makes it an ideal choice across a wide range of spraying systems.

Outstanding Performance in Practical Operation

In real-world use, the Dn rotary joint’s convenience shines through. Installation is quick and simple, requiring only basic tooling, which greatly reduces modification time for the equipment. The user interface is intuitive, allowing operators to become familiar with it after minimal training.

Once spraying begins, the rotary joint operates reliably. The mixed de-icing fluid flows smoothly through the optimised channel and is delivered evenly to the spray nozzles. Thanks to its stable-flow design, the common “striped” coverage pattern seen in traditional systems is eliminated. Additionally, the rotating component is made from low-friction materials, ensuring smooth operation, low noise, and a longer service life.

Economic Benefits and Maintenance Convenience

From a cost-control perspective, the DN rotary joint performs impressively. Its procurement cost is reasonable, and maintenance is simple, with only periodic inspection and cleaning required to keep it in optimal condition. Compared to traditional connection methods, it significantly reduces maintenance costs and downtime losses due to clogging. In terms of total cost of ownership, the advantage is clear.

By improving the utilisation rate of de-icing agent by about 20 – 30 % and reducing fuel and labour costs from repeat operations, the pay-back period often does not exceed one winter season. This economic feasibility enables both large sanitation companies and small municipal departments to adopt this upgrade with confidence.

Application Prospects and Future Development Trends

As the urbanisation process accelerates and extreme weather events become more frequent, winter road-maintenance work grows in urgency. The DN stainless steel rotary joint is not only applicable to traditional de-icing-agent spraying, but can extend to other special-liquid precision spraying fields—for example, insecticides, dust suppressants, or other chemical additives.

Looking ahead, with the integration of intelligent-control technologies, we can expect the emergence of smart rotary joints with remote monitoring, auto-adjustment, and IoT connectivity. These next-generation components will further enhance operational efficiency and precision.

Conclusion

The DN stainless steel rotary joint is a core component of water-truck spraying systems. Through technical innovation, it addresses longstanding industry pain-points—such as pipeline clogging, uneven spray, maintenance burden—and offers stable performance, ease of operation, and measurable economic benefits. It has become indispensable in winter road-maintenance operations.

For organisations and individuals engaged in road maintenance and winter-snow operations, choosing the Dn rotary joint is not just a technological upgrade—it is a step toward refined, professional road maintenance. When the cold season arrives, let this innovative technology safeguard your operations, keep roads open, and ensure pedestrian and vehicle safety.