What is a rotary union joint Used For? — A Complete Engineering Guide

In modern industrial machinery, transferring fluids or gases between stationary and rotating parts is a common challenge. Whether in manufacturing, automation, or heavy equipment, systems often require a continuous flow of air, oil, water, or coolant during rotation. That’s where the rotary union joint—also known simply as a rotary union or rotary joint—plays an essential role.

This article explains what a rotary union joint is, how it works, and where it is used. We’ll also cover its different types, design principles, and practical applications across industries.

Understanding the Rotary Union Joint

A rotary union joint is a precision mechanical device that enables the transfer of fluids or gases from a stationary source to a rotating component. It maintains a secure, leak-free connection while allowing continuous rotation.

The term “rotary union” is often interchangeable with “rotary joint,” and both describe the same function — transmitting media under pressure through a rotating interface.

These joints are vital in systems that require the movement of liquids, steam, hydraulic oil, air, or coolant while the connected parts rotate.

How Does a Rotary Union Joint Work?

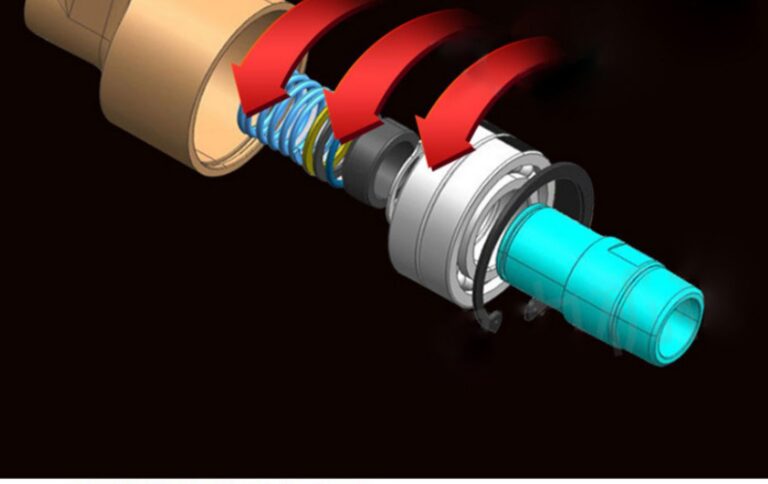

A rotary union joint works by combining advanced sealing and bearing technologies that allow rotation without leakage.

Inside the rotary union, there are two main parts:

-

Stationary Housing: Connected to the fluid supply line.

-

Rotating Shaft (or Spindle): Attached to the moving machinery part.

A mechanical seal or elastomer seal separates these two components. This seal ensures that the fluid or gas flows through internal passages while the rotating part turns freely.

Working Principle:

-

Fluid enters through the stationary inlet port.

-

The seal keeps the pressure contained.

-

The rotating shaft or drum receives the fluid through internal channels.

-

The fluid exits to perform its intended function (e.g., cooling, lubrication, actuation).

By maintaining this controlled fluid path, the rotary union joint enables efficient and reliable operation of rotating machinery.

Types of Rotary Union Joints

Different applications require different designs of rotary union joints. Here are the most common types:

a. Single-Passage Rotary Union

Used to transfer one medium—such as air, oil, or water—through a single flow path. Ideal for simple rotating systems like rolls, drums, or shafts.

b. Multi-Passage Rotary Union

Contains multiple independent flow channels for transferring various fluids simultaneously. For example, one passage may carry hydraulic oil, while another carries coolant or air. Common in CNC machines and automated equipment.

c. Pneumatic Rotary Union

Specially designed for air or vacuum transfer. Used in packaging, robotics, and pneumatic clutch systems.

d. Hydraulic Rotary Union

Built to handle high-pressure fluids. Common in construction machinery, injection molding equipment, and heavy-duty cranes.

e. Steam or Water Rotary Joint

Used in paper dryers, textile machinery, and heat exchangers to transfer steam or hot water while maintaining tight sealing at high temperatures.

f. High-Speed Rotary Union

Designed for applications where the rotating speed exceeds 10,000 RPM, ensuring stability and minimal vibration.

What is a Rotary Union Joint Used For?

The rotary union joint plays a vital role in numerous industries that require both fluid transfer and rotation. Below are the most common applications:

Hydraulic rotary unions in Machine Tools and Manufacturing

Coolant and Lubricant Delivery: In machine tools such as lathes, milling machines, and drilling machines, engineers use hydraulic rotary unions to deliver coolant and lubricants directly to the cutting tools. As a result, the tools stay cool and well-lubricated throughout operation, which improves machining efficiency and extends tool life.

Spindles and Rotating Components: The hydraulic rotary unions are used in spindles and other rotating components to provide a reliable fluid connection.

CNC Machining: Deliver high-pressure coolant (up to 140 bar) to spindles for precision cutting.

Packaging Machinery: Transfer air for pneumatic controls and vacuum for product handling.

Paper and Pulp Industry

In the papermaking industry, engineers use rotary joints to connect the drying cylinder of the paper machine with the fixed pipeline. This connection ensures a continuous supply of steam to the drying cylinder, allowing the system to dry the paper efficiently and maintain consistent production quality.

Steam and Water Transfer: Engineers use hydraulic rotary unions to transfer steam and water in paper-making machines. These unions connect efficiently to components like calendar rolls. They help control the flow of steam and water during operation. As a result, they support effective drying and finishing processes in paper production.

Coating and Laminating: In coating and laminating machines, Hydraulic rotary unions supply adhesives, coatings, and other fluids to the rotating parts.

Plastic and Rubber Processing

Mold Cooling and Heating: In injection molding, blow molding, and extrusion processes, Hydraulic rotary unions are used to circulate cooling water or heating fluids through molds to control their temperature.

Rotary Molds and Dies: Hydraulic rotary unions ensure consistent temperature control in rotating molds and dies, which is crucial for the quality of the final product.

Textile Industry

In the textile industry, engineers use rotary joints to connect the dyeing cylinder with the fixed pipeline. These joints ensure a continuous dye supply to the cylinder. As a result, the system maintains stable flow and consistent color application. This process helps achieve efficient and uniform textile dyeing.

Dyeing and Finishing: Hydraulic rotary unions are used in dyeing and finishing machines to supply dyes, chemicals, and hot water to the rotating drums or cylinders.

Winding and Unwinding: In winding and unwinding operations, Hydraulic rotary unions provide a fluid connection for tension control and lubrication.

Food and Beverage Industry

Cleaning and Sterilization: Hydraulic rotary unions are used in cleaning and sterilization systems to supply hot water, steam, and cleaning agents to rotating equipment, ensuring hygiene and food safety.

Beverage Filling and Packaging: Hydraulic rotary unions provide a fluid connection for the transfer of liquids and gases.

Hydraulic rotary unions in Aerospace and Defense

The role of rotary joints in the aerospace field: In aerospace vehicles, the rotary joint connects the rotating parts and the fixed pipeline to ensure that the hydraulic oil, fuel, and other fluids can be continuously supplied to ensure the normal operation of the aircraft.

Hydraulic and Pneumatic Systems: In aircraft and military vehicles, Hydraulic rotary unions are used in hydraulic and pneumatic systems to transfer fluids and gases to rotating parts, such as landing gear, weapons & radar antennas.

Satellite and Spacecraft: Hydraulic rotary unions are used in satellite and spacecraft systems for the transfer of fuel, coolant, and other critical fluids.

Chemical and Petrochemical Industry

Reactors and Vessels: Hydraulic rotary unions are used to supply and remove process fluids, such as reactants, solvents, and coolants.

Mixing and Blending: Hydraulic rotary unions are used in mixing and blending equipment to provide a fluid connection for the addition of ingredients and the removal of products.

Automotive Industry

Engine Testing and Development: Hydraulic rotary unions are used to supply and remove fluids for testing and development purposes.

Rotary Components: Hydraulic rotary unions are used in various automotive manufacturing processes, such as the assembly of engines and transmissions. Providing a fluid connection to rotating components.

Renewable Energy

Wind Turbines: Hydraulic rotary unions are used to transfer hydraulic fluid and other media to and from the nacelle. Enabling pitch control and yaw systems.

Solar Thermal Systems: Hydraulic rotary unions are used in solar thermal systems to transfer heat transfer fluids to and from rotating mirrors or receivers.

Hydraulic rotary unions in the agricultural field

Application of rotary joints in grain harvesting equipment (such as combine harvesters, tractors, etc.): Combine harvesters need rotating drums to separate grains and straw during harvesting. The rotary joint connects the drum and fixed pipeline to ensure that fluids such as hydraulic oil can be continuously supplied to the drum to achieve normal rotation.

Use of rotary joints in crop processing equipment (such as cooling conveyor belts, rice mills, etc.): In rice mills, the rotary joint connects the rice milling roller and fixed pipeline to ensure that cooling water can continuously supply to the rice milling roller to prevent it from overheating.

Automobile manufacturing industry

The key role of rotary joints in the manufacturing and assembly of automobile parts: In the manufacturing and assembly of automobile engines, gearboxes, and other parts, rotary joints connect rotating parts and test equipment to ensure that fluids such as coolant and lubricating oil.

In the test of automobile wheel hub bearings, the rotary joint connects the test equipment and the wheel hub bearing to ensure that the test fluid can continuously supply to the bearing to simulate the lubrication conditions during actual driving.

Oil and gas drilling industry

During oil and gas drilling, rotary joints connect the drill bit and fixed pipelines to ensure that drilling fluid can continuously supply to the drill bit so that drilling can proceed smoothly.

Marine engineering industry

On deep-sea drilling platforms, rotary joints connect drill pipes and fixed pipelines to ensure that drilling fluid and mud can continuously supply to the drill pipe so that deep-sea drilling can proceed smoothly. With its high-pressure and corrosion-resistant properties, rotary joints play an important role on deep-sea drilling platforms.

Design Considerations for Rotary Union Joints

When selecting a rotary union joint, engineers must consider several critical factors to ensure optimal performance:

-

Operating Pressure and Temperature: Choose materials and seals compatible with system conditions.

-

Rotational Speed: High-speed applications require balanced designs and precision bearings.

-

Media Type: The fluid or gas dictates seal material selection.

-

Number of Passages: Multi-passage unions are ideal for complex systems.

-

Environment: Corrosive, dusty, or high-moisture environments may require stainless steel construction or additional protection.

Conclusion

A rotary union joint is a fundamental component in any system that requires fluid transfer through rotation. By combining precision sealing, mechanical strength, and reliability, it enables industries to achieve higher efficiency, lower maintenance, and greater safety.

From CNC machines and printing rolls to chemical reactors and wind turbines, rotary union joints ensure that fluids flow smoothly and continuously—without compromising performance.

As machinery becomes faster and more complex, the importance of high-quality rotary union joints continues to grow, making them an indispensable part of modern engineering and industrial automation.