360° Universal Rotary Joint: A Key Driver for Equipment Upgrades Across Multiple Industries

Driven by the technological wave, equipment across various industries is undergoing unprecedented transformation and upgrades, achieving a qualitative leap in function and performance. In numerous fields such as agricultural sprinkler systems, water trucks, and tower cranes, the application of 360° universal rotary joint shines like a bright star, becoming a crucial technological support for improving equipment performance and optimizing the user experience, injecting new vitality into industry development.

Agricultural Sprinkler System: Precision and Efficiency, Ushering in a New Chapter in Smart Agriculture.

In the vast farmlands, every stage of crop growth relies on precise water and nutrient supply, and efficient spraying equipment is key to achieving this goal. Traditional agricultural spraying equipment, limited by its structural design, often requires frequent manual adjustments during operation, resulting in high labor intensity and difficulty in achieving comprehensive and uniform spraying. Especially in large-scale farmland operations, the limitations of manual operation become increasingly apparent, easily leading to uneven spraying and missed areas, affecting crop growth and yield.

The advent of the 360° Universal Rotary Joint has revolutionized agricultural spraying. Its unique structural design endows spraying equipment with flexible steering and free operation. By connecting with the spraying arm and nozzle, the 360° universal joint rotates freely. This joint enables agricultural spraying equipment to cover every farmland corner without blind spots. It gives spraying systems flexible “arms” for precise maneuvering and efficient coverage. Whether on large plains or complex hilly terrain, spraying remains uniform and precise. 360° universal joint spraying arms significantly enhance efficiency in precision agriculture. Using these joints supports modern farming with automated and intelligent spraying systems. They optimize pesticide and water application, improving crop protection and sustainability.

On large farms that grow wheat or corn, 360° universal joints enhance spraying efficiency. Spraying equipment featuring 360° universal joint technology enables the completion of large-area pesticide or irrigation tasks quickly. Compared to traditional systems, these joints reduce operation time and lower labor costs. High-strength materials and advanced sealing technology make the joint durable and reliable. 360° universal joints operate stably in harsh agricultural environments, including sun or rain. They ensure that spraying equipment works normally, protecting crop growth effectively. In smart agriculture, 360° universal joints integrate with intelligent control systems. Sensors monitor soil moisture and crop growth for automated spraying operations. The intelligent system adjusts spray angle, volume, and speed automatically. This supports precision agriculture and improves water and pesticide efficiency. 360° universal joints reduce environmental pollution while enhancing resource utilization. They enable sustainable agricultural development and modern farming solutions.

Sprinkler Trucks: Flexible and Versatile, Meeting Diverse Urban Cleaning and Greening Needs

In the streets and alleys of cities, sprinkler trucks are important tools for maintaining urban environmental sanitation and carrying out greening maintenance. Traditional sprinkler trucks typically have fixed spray angles and directions, which present many inconveniences in actual use. For example, when washing roads, a fixed spray angle is insufficient to achieve ideal cleaning results in narrow streets or corners; when irrigating green spaces, it is impossible to flexibly adjust the spray direction according to the different growth needs and locations of plants, easily leading to water waste.

The application of the 360° Universal Rotary Joint has brought a revolutionary change to sprinkler trucks, greatly enhancing their flexibility. By installing this joint on the sprinkler truck’s spraying system, the truck can freely adjust the spray angle and direction according to actual needs, achieving all-around, multi-angle spraying operations. Whether it’s a wide road, a narrow alley, or roadside green belts and park trees and shrubs, precise spraying and irrigation can be achieved.

In urban road cleaning, sprinkler trucks use 360° universal joints for flexible operation. These joints adjust spray angle and water volume based on road width and pollution. For heavily polluted sections, spray intensity and water volume increase for deep cleaning. At intersections and bus stops, spray direction adjusts precisely to avoid pedestrian inconvenience. This flexible spraying method improves road cleaning efficiency and quality significantly. It helps create a cleaner and more comfortable urban environment. 360° universal joints support versatile and intelligent water spraying systems for cities.

The role of this joint in green space maintenance is equally important. Different types of plants have different water requirements, and their growth locations also vary. By using a 360° Universal Rotary Joint, the sprinkler truck can precisely control the spray direction and water volume according to the characteristics and location of the plant, providing each plant with the appropriate amount of water to meet its growth needs.

At the same time, this precise irrigation method can also avoid water waste and improve water resource utilization efficiency, which is of great significance for urban water conservation efforts. Furthermore, the 360° swivel joint design makes the sprinkler truck operation simpler and more convenient. Operators can easily adjust the spray angle and direction through the control device, without having to get off the truck for manual operation, greatly improving work efficiency and reducing labor intensity. Moreover, the joint is also very easy to install and maintain, without significantly affecting the original structure of the sprinkler truck, reducing equipment operating costs.

Tower Crane Industry: Free Rotation, Enhancing Construction Safety and Efficiency

Tower cranes, as the “giants” of construction sites, are indispensable and important equipment in construction, undertaking critical tasks such as material hoisting and component installation. However, traditional tower crane operation is often limited by fixed positions and angles, leading to inconvenience and inefficiency in complex and changing construction environments. For example, when hoisting certain special components, the limited rotation angle of the tower crane may require multiple adjustments to its position to accurately move the component to the designated location, wasting time and increasing construction risks.

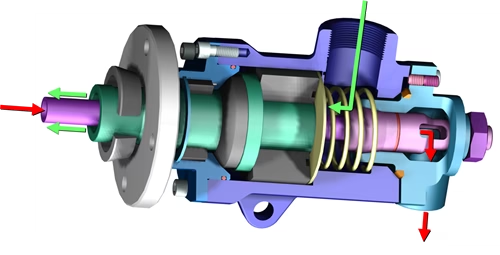

The application of the 360° universal slewing joint has brought a new breakthrough to the tower crane industry. By installing this joint in key parts of the tower crane, such as between the tower body and the slewing mechanism, or at the connection between the jib and the tower body, the tower crane can achieve 360-degree free rotation and positioning. Operators can flexibly control the position and angle of the tower crane according to construction needs, without frequently moving the tower crane base, greatly improving operational flexibility and convenience.

This advantage is particularly evident in high-rise building construction. When materials need to be hoisted between different floors, tower cranes equipped with 360° universal slewing joints can quickly and accurately move materials to designated floors and locations without repeatedly adjusting the overall position of the tower crane, saving significant time and labor costs. Furthermore, when hoisting large, irregularly shaped components, this joint allows the tower crane to adjust its angle more flexibly, ensuring the stability and safety of the components during transport and reducing the risk of accidents caused by collisions, swaying, etc.

In addition, the 360° Universal Rotary Joint also features high-precision positioning. Through an advanced transmission and control system, the tower crane can achieve precise angle positioning and fine-tuning, meeting the stringent precision requirements of construction projects. In projects with high precision requirements, such as bridge construction and large stadium construction, this joint ensures that the tower crane accurately installs components into designated positions, improving project quality.

Meanwhile, with the continuous development of the construction industry, the requirements for the safety and reliability of tower cranes are also increasing. The 360° universal slewing joint uses high-strength materials and advanced manufacturing processes, possessing excellent wear resistance, corrosion resistance, and fatigue resistance, enabling it to operate stably for extended periods in harsh construction environments. Moreover, this joint is equipped with comprehensive safety protection devices, such as limit switches and overload protection, which can promptly detect and handle abnormal situations, ensuring the safe operation of the tower crane.

Industrial Cleaning Field

In the cleaning of large industrial equipment, 360° omnidirectional joints play a crucial role. For example, ships often accumulate dirt and marine organisms. The hull, deck, and cabins are especially prone to buildup. Traditional cleaning methods struggle to reach every corner. Cleaning equipment uses 360° omnidirectional rotary joints. These joints let nozzles adjust angle and direction freely. They adapt to the hull shape and dirt distribution easily. This design enables comprehensive and uniform cleaning. 360° universal rotary joints also increase cleaning efficiency. They clean upright hull surfaces without manual repositioning. They also reach curved bows and sterns effectively. These systems improve cleaning effectiveness and coverage. They reduce total cleaning time and labor costs significantly.

In the cleaning of chemical equipment, the complex internal structure, with numerous pipes, valves, reaction vessels, and other components, makes cleaning challenging. Using cleaning equipment with 360° omnidirectional joints allows for deep penetration into the equipment, flexible adjustment of the cleaning angle, and thorough cleaning of each component, removing residual chemicals and dirt, ensuring the normal operation of the equipment and product quality.

Fire Protection Area

In firefighting operations, 360° swivel joints enhance the flexibility and extinguishing efficiency of firefighting equipment. Fire truck monitors typically need to handle various complex fire scenarios, such as high-rise building fires and large warehouse fires. Traditional fire monitors have a limited spray angle and adjustment range. This limitation reduces the effectiveness of precision fire suppression systems. Fire monitors with 360° swivel joint technology adjust spray angles quickly. They allow flexible targeting of fires at various heights and positions. 360° swivel joint fire monitors provide accurate water spraying onto fire sources. They work effectively for high-rise windows, rooftops, and warehouse corners. Fire-fighting systems equipped with 360° swivel joints improve fire extinguishing efficiency. These systems reduce fire damage by precisely controlling water application. Using 360° swivel joint monitors enhances safety in industrial and commercial environments. Advanced 360° swivel joint fire monitors support intelligent and automated fire suppression solutions.

In large event venues, shopping malls, and other densely populated areas, fire sprinkler systems equipped with 360° swivel joints can flexibly adjust the spray direction and range according to the layout and personnel distribution, enabling rapid and effective firefighting and personnel evacuation guidance during a fire, ensuring the safety of people.

Stage Lighting and Sound Equipment

In large-scale stage performances, the creation of lighting and sound effects is crucial. A 360° universal joint provides flexible installation and adjustment options for stage lighting and sound equipment. For stage lighting equipment, this joint allows lights to rotate and adjust their angles freely in three-dimensional space according to the performance’s needs, achieving various unique lighting effects such as spotlighting, focused lighting, and color rendering, enhancing the stage’s visual impact and artistic appeal. Whether it’s a concert, theatrical performance, or dance performance, the flexible adjustment of lighting angles can create an atmosphere that matches the performance content.

Regarding sound equipment, the 360° universal joint adjusts speaker directivity easily. The joint allows flexible angle and position changes. It ensures sound is accurately projected to the audience area. This improves overall sound coverage and clarity. In large concerts and stadium events, the benefit is greater. Operators adjust speaker angle and direction as needed. The audience hears clear and immersive sound effects. People in different locations enjoy consistent audio quality. This upgrade enhances the entire viewing and listening experience.

Looking to the Future: Expanding into Multiple Fields and Leading New Trends in Industry Development

In summary, the 360° universal rotary joint has achieved remarkable results in the application of equipment in industries such as agricultural sprinklers, water trucks, and tower cranes, bringing tremendous impetus to the development of these industries. It not only improves the flexibility and ease of operation of equipment but also enhances work efficiency and safety, becoming an indispensable component in modern industrial and agricultural development.

With continuous technological advancements and wider applications, the application fields of the 360° universal rotary joint will continue to expand. In environmental protection, engineers use 360° universal rotary joints for sewage treatment equipment. These joints ensure the flexible and efficient operation of wastewater and waste management systems. In the energy sector, wind turbines employ 360° rotary joints in yaw mechanisms. Solar tracking systems also use these joints to improve energy efficiency. 360° universal rotary joints in energy systems enhance power utilization and system performance. In transportation, ship steering systems integrate 360° rotary joints for precise control. Aircraft landing gear systems also incorporate these joints to ensure operational reliability. These applications improve safety and performance in industrial and transportation systems. 360° universal rotary joints support automation, precision control, and sustainable industrial solutions.

It is foreseeable that the 360° universal rotary joint will keep innovating in the future. The joint will continue to improve, offering higher-quality and more efficient technical support. It supports the development of various industries with advanced and reliable performance. The 360° universal joint will integrate with emerging technologies like artificial intelligence. It will also work with the Internet of Things for intelligent equipment control. This integration enables automated control of industrial machinery and production processes. As a result, industries can achieve smarter, greener, and more efficient development. With the 360° universal rotary joint, living and working environments will improve. It helps industries enhance productivity, safety, and environmental sustainability. We believe this technology will drive a brighter and more promising industrial future.