What types of rotary joints are available?

Rotary Joint Definition

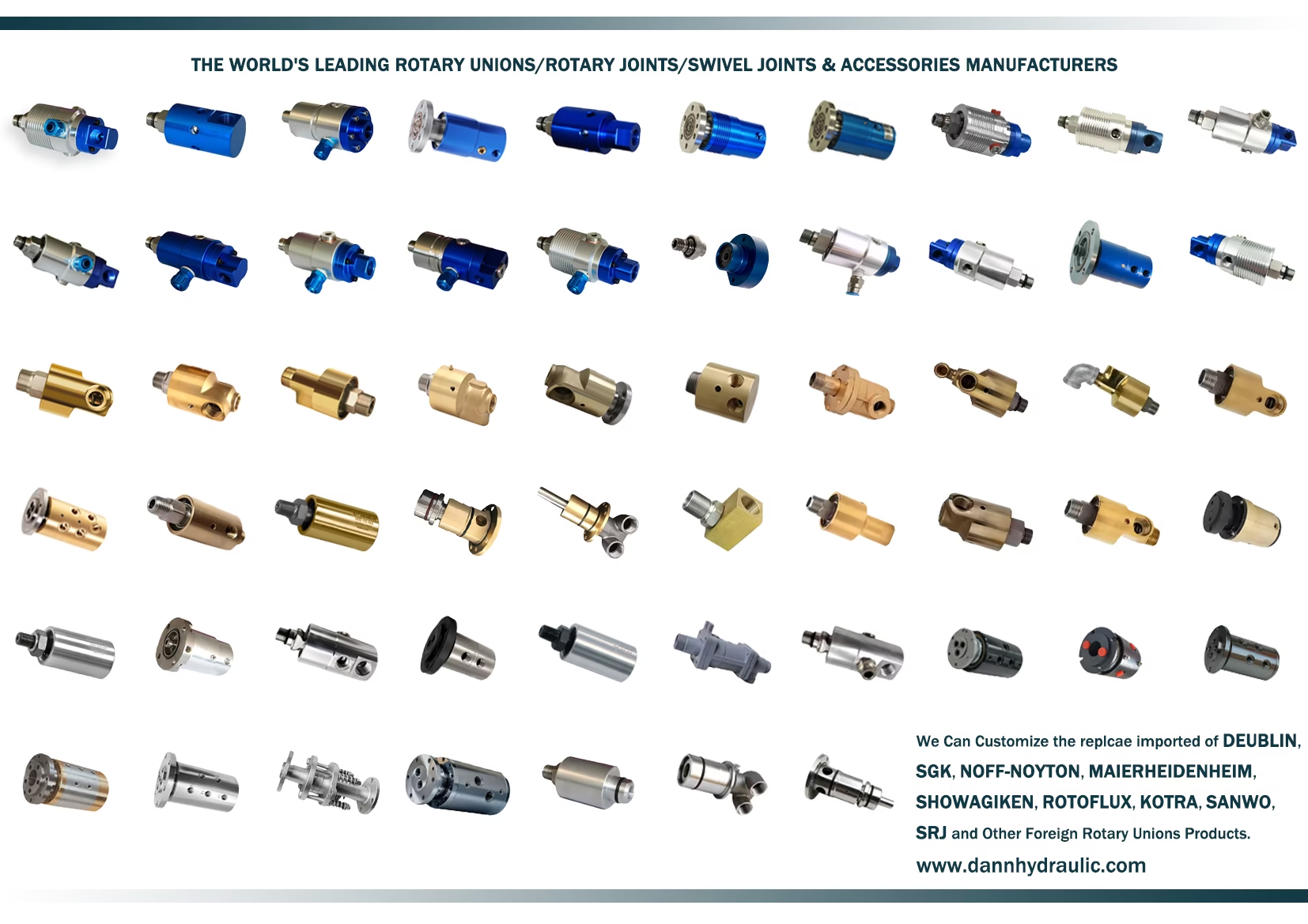

Rotary joints, also known as rotary unions or swivel joints, are critical components in industrial machinery, enabling the transfer of fluids, gases, or electrical signals between stationary and rotating systems. With advancements in engineering and diverse industrial demands, rotary joints now come in various configurations tailored to specific applications. Here are the types of rotary joints classification.

Types of Rotary Joints

1.1 Fluid Transfer Rotary Joints

Hydraulic Rotary Joints

Hydraulic rotary joints are engineered to handle high pressures and ensure reliable, leak-free fluid transfer while maintaining smooth rotational movement.

Technical Specifications: Pressure resistance ≥300 bar, alloy steel construction.

Innovations: Pressure-adaptive mechanical seals for reduced wear.

Applications: Used in hydraulic systems to transfer fluid between stationary and rotating components. Essential for machinery that requires hydraulic power, ensuring smooth operation. Injection molding machines, excavator hydraulic systems.

Hydraulic rotary joints are essential components in modern industrial and mobile hydraulic systems, enabling efficient and reliable fluid transfer between stationary and rotating parts. Their ability to handle high pressures, operate in extreme temperatures, and integrate seamlessly into complex machinery makes them indispensable in a wide range of applications. By selecting the right hydraulic rotary joint for your specific needs, you can ensure optimal performance, minimize downtime, and achieve significant cost savings.

Coolant Rotary Joints

Coolant rotary joints are specialized devices design to transfer cooling fluids (such as water, oil, or water-based coolants) between stationary and rotating parts of machinery. These joints are critical in applications where continuous cooling required to maintain optimal operating temperatures, prevent overheating, and ensure the longevity of equipment.

Materials & Seals: 316L stainless steel housing + tungsten carbide seals, corrosion-resistant for CNC machine tools.

Coolant rotary joints engineered to handle various types of coolants under different pressure and temperature conditions while maintaining leak-free operation. They play a vital role in industries such as manufacturing, automotive, aerospace, and metalworking.

Steam Rotary Joints

Steam rotary joints, also known as steam swivel joints or steam rotary unions, specialized devices design to transfer steam between stationary and rotating parts of machinery. These joints are essential in applications where steam used for heating, drying, or sterilization, ensuring efficient and leak-free operation even under high temperatures and pressures.

Specifically designed for steam applications, often found in paper and textile industries.

Facilitate efficient heat transfer and drying processes.

High-Temperature Performance: Withstands ≤300°C, graphite seals, used in paper drying systems (14 bar pressure support).

Water Rotary Joints

Water rotary joints, also known as water swivel joints or water rotary unions, are mechanical devices design to transfer water or water-based fluids between stationary and rotating parts of machinery. These joints are engineered to ensure leak-free operation, corrosion resistance, and durability in applications requiring continuous water flow for cooling, lubrication, or hydraulic power transmission.

Water rotary joints are essential components in industries requiring reliable water transfer for cooling, hydraulic power, or irrigation. Their corrosion-resistant materials, leak-free sealing, and adaptability make them ideal for applications ranging from precision machining to agricultural systems. By selecting a joint that matches the water type, pressure, and rotational speed, businesses can optimize efficiency and reduce maintenance costs.

1.2 Gas Transfer Rotary Joints

Air Rotary Joints:

Lightweight aluminum alloy, ideal for pneumatic tools and automated production lines.

Air rotary joints, also known as pneumatic rotary unions or air swivel joints, are mechanical devices design to transfer compressed air or other gases between stationary and rotating parts of machinery. They ensure leak-free, continuous airflow in applications such as pneumatic tools, robotics, and automated systems, enabling efficient operation and precise control.

Vacuum Rotary Joints

Vacuum rotary joints specialized devices design to transfer vacuum pressure or gases between stationary and rotating parts of machinery. These joints are essential in applications requiring a controlled vacuum environment, such as semiconductor manufacturing, vacuum coating, and scientific research.

Sealing Technology: Magnetic fluid seals for ultra-high vacuum (≤10⁻³ Pa), used in semiconductor manufacturing.

1.3 Signal Transfer Rotary Joints

High-Frequency Signal Joints

Broadband support, applied in radar and satellite communications.

Fiber Optic Rotary Joints (FORJ): Multi-channel transmission, used in wind turbine yaw systems for real-time data transfer.

2. Classification by Structural Design

2.1 Single vs. Multi-Passage

Single-Passage Rotary joints

Simple design for single-media transfer (e.g., Deublin 1080-Series).

Single-passage rotary joints, also known as single-channel rotary unions or swivel joints, are mechanical devices design to transfer a single medium (such as fluid, gas, or air) between stationary and rotating parts of machinery. These joints characterized by their simple design, cost-effectiveness, and reliability, making them ideal for applications requiring the transfer of one type of medium.

Multi-Passage Rotary joints(2-12 Channels)

Complex Internal Design: Kadant 12-Pass Rotary Union for multi-media transfer in excavator hydraulics.

Independent Channels: Dual-circuit joints with labyrinth seals to prevent cross-contamination.

Multi-passage rotary joints, also known as multi-port rotary unions or multi-channel rotary couplings, are advanced mechanical devices design to transfer multiple types of media (such as fluids, gases, or a combination thereof) between stationary and rotating parts. These rotary joints feature several independent passages within a single unit, enabling simultaneous fluid transfer without mixing different media. They widely used in industries requiring complex fluid management systems, such as manufacturing, robotics, aerospace, and renewable energy.

Designed to transfer multiple fluids simultaneously through separate passages.

Ideal for complex systems requiring different media to be handled at once.

2.2 Axial vs. Radial Flow

Axial Flow: Compact design with media flow along the axis types of rotary joints.

Radial Flow: Radial media flow for easy piping (common in steel mill cooling systems).

2.3 Modular vs. Integrated

Modular: Detachable for maintenance.

Integrated: High sealing integrity for extreme pressure.

3. Classification by Sealing Technology

3.1 Contact Seals

Mechanical Seals: Precision-ground surfaces for high-pressure hydraulics.

O-Ring Seals: Cost-effective for low-pressure pneumatics (≤10 bar, e.g., DuraSeal™).

3.2 Non-Contact Seals

Labyrinth Seals: Frictionless design for high-speed turbines (>20,000 rpm).

Magnetic Fluid Seals: Zero leakage in vacuum environments.

4. Classification by Material & Environmental Resistance

4.1 Metal Materials

Stainless Steel (316L/304) rotary joints

Stainless steel rotary joints, also known as stainless steel rotary unions or rotary couplings, are specialized mechanical devices design to transfer fluids, gases, or other media between stationary and rotating components. These rotary joints constructed from stainless steel, a material known for its exceptional corrosion resistance, durability, and strength. Stainless steel rotary joints are ideal for applications in harsh environments where exposure to corrosive substances, extreme temperatures, or high pressures is common.

Alloy Steel

High-pressure resistance (210 bar, e.g., Wenshung RS-Series for heavy machinery).

4.2 Composite Materials

Ceramic-Metal Hybrid: Heat-resistant up to 800°C.

PTFE Coating: Chemical resistance for acidic media in chemical processing.

5. Classification by Industry Applications

5.1 Heavy Industry

Steel Mill Joints: Heat-resistant (500°C) with multi-coolant channels (e.g., Rotary Systems H-Series).

Wind Turbine Yaw Joints: Vibration-resistant design.

5.2 Precision Manufacturing

Semiconductor Vacuum Joints: Ultra-clean.

Medical Equipment Joints: FDA-certified materials.

5.3 Emerging Sectors

Collaborative Robots: Miniaturized design.

Battery Production Lines: Explosion-proof for electrolyte transfer.

6. Innovations & Customization

6.1 Smart Rotary Joints

Sensor Integration: Real-time monitoring (pressure, temperature) via IoT.

6.2 Modular Quick-Change Systems

Field-replaceable components (e.g., Deublin Quick-Change Series) to minimize downtime.

6.3 Custom Large-Scale Joints

Ship propeller systems (diameter >1 meter, seawater corrosion resistance).

7. Other common type

7.1 High-Speed Rotary Joints

High-speed rotary joints, also known as high-speed rotary unions or swivel joints, are specialized devices designed to transfer fluids, gases, or electrical signals between stationary and rotating parts of machinery operating at extremely high rotational speeds. These joints are engineered to withstand the mechanical stresses and thermal effects associated with high-speed applications, ensuring reliable and leak-free performance.

Engineered to handle high rotational speeds while maintaining a reliable connection.

Suitable for applications like high-speed machining centers and rotary index tables.

7.2 High-Pressure Rotary Joints

High-pressure rotary joints, also known as high-pressure rotary unions or swivel joints, are specialized devices design to transfer fluids or gases between stationary and rotating parts of machinery under extreme pressure conditions. These joints are engineered to handle extreme pressures while maintaining reliability, durability, and leak-free operation. They play a crucial role in various industries where fluid transfer under high pressure is necessary for optimal performance and safety.

Built to withstand pressures above normal operating ranges.

These joints are constructed with robust materials and seals to ensure integrity under high-pressure conditions.

7.3 High-Temperature Rotary Joints

High-temperature rotary joints, also known as high-temperature rotary unions or swivel joints, are specialized devices design to transfer fluids, gases, or steam between stationary and rotating parts of machinery operating under extreme heat conditions. These joints are engineered to withstand thermal stress, maintain sealing integrity, and ensure reliable performance in high-temperature environments.

Designed to operate effectively at elevated temperatures.

Incorporate specialized materials and cooling mechanisms to prevent overheating during operation.

Rotary Joint Applications

1. Industrial Machiner

Hydraulic Systems: Rotary joints enable the transfer of hydraulic fluids to power actuators, cylinders, and motors in heavy machinery like excavators, cranes, and agricultural equipment.

Cooling Systems: Machine tools and industrial processing equipment transfer coolant to keep machinery at optimal operating temperatures, improving efficiency and extending tool life.

2. Printing Industry

Roller Coating: Rotary joints supply ink and water to rollers in printing presses, ensuring even distribution for high-quality print outputs.

Heat Setting: They can transfer steam or hot oil to dryers in heat-setting processes for textiles and paper production.

3. Paper Manufacturing

Calender Rolls: Water, steam, or thermal oil is transferred through rotary joints to calender rolls for precise temperature control during paper manufacturing.

Press Section: They facilitate the transfer of water used in the press section to remove excess moisture from the paper web.

4. Textile Industry

Dyeing Machines: Rotary joints provide dye solutions to textile machines, ensuring consistent application throughout the fabric.

Finishing Processes: They transfer liquids used in washing, softening, and finishing fabrics.

5. Renewable Energy

Wind Turbines: Hydraulic fluid, cooling fluids, and lubricants are transferred via rotary joints to pitch and yaw mechanisms, which are essential for wind turbine operation.

Solar Panels: They may use to transfer coolant for temperature regulation in concentrated solar power systems.

6. Marine and Offshore

Shipbuilding: Rotary joints transfer seawater, freshwater, hydraulic fluids, and other media on marine vessels, especially in harsh environments.

Offshore Platforms: They supply fluids necessary for drilling operations and maintenance activities on offshore oil rigs and renewable energy installations.

7. Food and Beverage

Processing Equipment: Rotary joints used to handle clean-in-place (CIP) systems, transferring cleaning fluids efficiently and safely within food processing lines.

Pasteurization and Sterilization: They transfer steam or hot water for pasteurizing and sterilizing products to ensure hygiene standards are met.

8. Automotive Manufacturing

Assembly Lines: Fluids required for assembly line operations, including lubricants and coolants, transferred using rotary joints.

Testing Equipment: They play a role in test rigs where multiple media types need to be circulated simultaneously.

9. Medical Devices

Diagnostic Equipment: Rotary joints enable the precise transfer of fluids within medical imaging and diagnostic machines.

Surgical Tools: They supply coolant or hydraulic fluid to surgical instruments, maintaining sterility and performance.

10. Aerospace

Gimbals and Rotating Platforms: These joints transfer hydraulic fluid, fuel, or coolant through stainless steel rotary joints for reliable operation in aerospace applications.

Test Rigs: Simultaneously supplying hydraulic fluid and coolant for testing equipment under simulated conditions..

Rotary joints are indispensable in industries requiring reliable, leak-free transfer of media in rotating systems. From cooling CNC spindles to enabling wind turbine hydraulics, their versatility drives efficiency and innovation. By selecting the right joint for specific applications—whether high-speed, high-pressure, or ultra-clean—businesses can optimize performance and reduce downtime.

How to Choose Rotary Joint: Key Considerations

Since there are so many types of rotary joints, how do we choose the right one:

Operating Parameters: Speed, pressure, temperature, and media compatibility.

Mounting Style: Self-supported vs. bracket-mounted joints for alignment flexibility.

Material Compatibility: Ensure resistance to corrosion, abrasion, or thermal stress.

Conclusion

From hydraulic systems in construction vehicles to high-frequency signal transmission in aerospace, rotary joints are indispensable across industries. Innovations in materials, sealing technology, and multi-passage designs continue to expand their applications. By understanding the types available—categorized by media, structure, material, and industry—engineers can optimize machinery performance and longevity.

For further details on specific models or types of rotary joints knowledge, contact us directly.

One Comment