High Pressure Rotary Union- Durable, and Flexible Fluid Transfer Solution

Original price was: $70.00.$60.00Current price is: $60.00.

- Material: Stainless steel

- Pipe clamp Size: 32/40/50

- Max.Speed: 100RPM

- Max. Pressure: 5MPa

- Max. Temperature: 220°C

- Applicable Medium: Oxygen, air, superheated water, oil

Description

Product Details

Our High Pressure Rotary Union is specifically designed to provide a flexible and reliable connection for fluid transfer between rigid pipelines. Engineered to accommodate reciprocating or low-speed rotational movements, this rotary union offers superior performance under high-pressure conditions. Built to endure challenging environments, it guarantees excellent wear resistance, exceptional rotational flexibility, and strong support, making it ideal for various industrial applications.

Key Features

High Pressure Performance

Designed to handle high-pressure fluid transfer applications, ensuring optimal performance even under extreme operational conditions.

Flexibility in Motion

Our rotary union provides smooth and flexible rotational motion, capable of supporting reciprocating and low-speed rotations, ensuring continuous fluid transfer without interruptions.

Superior Wear Resistance

Manufactured with advanced materials, the rotary union offers high wear resistance, ensuring longevity and reducing the need for frequent maintenance.

Strong Support Capacity

With robust structural design, it offers exceptional load-bearing capacity, providing stability during high-pressure fluid transfer.

Sealing Technology

Featuring German OBO Seals, renowned for their high-quality sealing performance, this rotary union ensures reliable and consistent sealing under pressure, preventing leaks and maintaining system integrity.

Versatile Applications

Ideal for fluid transfer in industries such as oil and gas, automotive, machinery, and manufacturing, where high-pressure fluid movement is required.

Technical Specifications:

-

Material: High-grade stainless steel (SS304/SS316) for corrosion resistance and long-lasting durability.

-

Sealing System: German OBO Seals for superior leak prevention and reliable sealing.

-

Pressure Range: Up to [insert pressure range] bar, ensuring high-pressure handling for demanding applications.

-

Temperature Range: Operates effectively in a wide temperature range from [insert temperature range] °C, making it suitable for diverse operational environments.

-

Rotational Speed: Optimized for low-speed and reciprocating movements, ideal for machinery and equipment that require continuous fluid transfer under rotation.

-

Applications: Primarily used in high-pressure fluid systems, including hydraulic machinery, oil & gas pipelines, industrial cooling systems, and more.

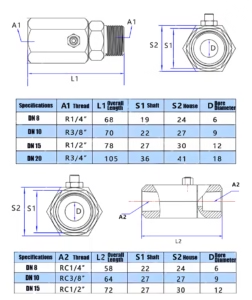

Imperial Thread Comparison Table

| Nominal Size | English Size | American Size | External Thread Diameter (mm) | Flow Diameter (mm) | Flow Capacity (m³/h) |

|---|---|---|---|---|---|

| 2 inches (DN8) | 1/4 | 19 | ~13 | ~11.5 | 6 |

| 3 inches (DN10) | 3/4 | 19 | ~16.5 | ~15 | 9 |

| 4 inches (DN15) | 1/2 | 14 | ~21 | ~18.5 | 12 |

| 6 inches (DN20) | 3/4 | 14 | ~26.5 | ~24 | 16 |

| 1 inch (DN25) | 1 | 11 | ~33 | ~30 | 22 |

| 1.2 inches (DN32) | 1-1/4 | 11 | ~42 | ~39 | 30 |

| 1.5 inches (DN40) | 1-1/2 | 11 | ~48 | ~45 | 35 |

| 2 inches (DN50) | 2 | 11 | ~60 | ~57 | 48 |

Benefits

Benefits

Reliability

With advanced sealing technology, our High-Pressure Rotary Union ensures minimal maintenance and maximized uptime.

Efficient Fluid Transfer

Smooth and uninterrupted flow of fluids under high pressure, enhancing system efficiency.

Enhanced Durability

Built to withstand wear and tear, this product guarantees long-term service life, reducing operational costs.

Versatility

Perfect for various industrial applications, providing consistent performance regardless of the medium being transferred.

Easy Installation

Designed for simple integration with rigid pipelines, the rotary union provides hassle-free installation in various configurations.

Applications

-

Hydraulic Systems: Ensures efficient fluid transfer in hydraulic machinery, reducing wear and prolonging system life.

-

Oil and Gas Industry: Designed to withstand the harshest conditions, it efficiently transfers fluids under high pressure in oil rigs, subsea systems, and drilling operations.

-

Industrial Cooling: Perfect for systems requiring precise fluid handling and cooling in machinery or industrial plants.

-

Manufacturing and Automotive: Used in automated machinery, ensuring smooth fluid transfer during high-speed manufacturing or assembly processes.

Why Choose Our High Pressure Rotary Union?

Our High Pressure Rotary Union is the ideal solution for industries that require high-performance fluid transfer under demanding conditions. With its superior wear resistance, seamless rotational movement, and German OBO Seals, it guarantees reliable, efficient, and long-lasting performance. Whether you are in hydraulic systems, oil and gas, or industrial equipment, this rotary union is engineered to meet the high standards of modern machinery and industrial systems.