Special Rotating Joint for High-Pressure Car Washing Machines

In the fast-paced world of car wash operations, efficiency, durability, and performance are paramount. Whether it’s a busy commercial car wash facility or a professional mobile service. High-pressure car washing machines rely on a multitude of components to deliver the powerful streams of water. That blasts away dirt, grime, and debris from vehicles. Among these components, one stands out as a critical yet often overlooked linchpin: the rotating joint. This small but mighty part enables the seamless movement of high-pressure water between stationary hoses and rotating brushes, nozzles, or arms. Ensuring that every inch of a vehicle receives the thorough cleaning it needs.

In this comprehensive blog, we delve into the world of special rotating joints for high-pressure car washing machines. Examining their design, functionality, benefits, applications, and maintenance requirements. By the end, you’ll understand why these rotating joints are indispensable to the success of any car wash operation.

Understanding the Role of Special Rotating Joints in High-Pressure Car Washing Machines

High-pressure car washing machines operate by forcing water through a system of pumps, hoses, and nozzles. At pressures ranging from 1,000 to 5,000 PSI (pounds per square inch) or more. This high pressure is what allows the water to dislodge tough dirt and grime without the need for excessive scrubbing. However, to cover all surfaces of a vehicle, from the roof and hood to the sides and undercarriage. Many car wash systems incorporate rotating components: spinning brushes, oscillating nozzles, or rotating arms that reach around the vehicle.

This is where the special rotating joint comes into play. It serves as the connection point between the stationary part of the machine (which includes the pump and supply hoses). And the rotating part (such as the brush assembly or nozzle arm). The rotating joint must maintain a watertight seal even as it spins, ensuring that the high-pressure water flows continuously without leaks or pressure loss. Without a reliable rotating joint, the machine would struggle to deliver consistent water pressure to the rotating components. This leads to uneven cleaning, wasted water, and increased wear and tear on other parts of the system.

How Special Rotating Joints Work

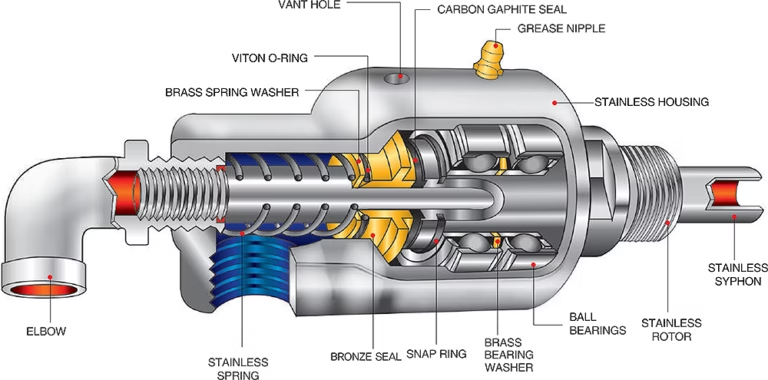

A special rotating joint for a high-pressure car washing machine is a precision-engineered device designed to handle both high pressure and continuous rotation. It consists of two main parts: a stationary housing and a rotating shaft. The stationary housing connects to the high-pressure water supply hose. The rotating shaft attaches to the moving component (brush, nozzle, or arm).

Inside the joint, a series of seals—typically made from durable materials. Like polyurethane, nitrile rubber, or PTFE (polytetrafluoroethylene)—create a tight barrier between the stationary and rotating parts. These seals must withstand the intense pressure of the water passing through them. As well as the friction generated by the rotating shaft. Some advanced rotating joints also include bearings to reduce friction and ensure smooth rotation, even during extended use.

As water flows into the stationary housing. It passes through internal channels and exits through the rotating shaft, which directs the water to the cleaning tool. The seals prevent water from leaking out at the point where the stationary and rotating parts meet. Ensuring that all the pressure is maintained and directed toward cleaning the vehicle.

Key Design Features of Special Rotating Joints for High-Pressure Car Washes

Not all rotating joints are created equal. Those designed specifically for high-pressure car washing machines boast unique features that make them ideal for the task. Here are some of the most important design elements that set these rotating joints apart:

High-Pressure Resistance

The most critical feature of a special rotating joint for high-pressure car washes withstands extreme water pressure. Car wash machines often operate at pressures between 2,000 and 4,000 PSI. And some industrial models can reach up to 5,000 PSI or more. The rotating joint must be constructed from materials that can handle this pressure without cracking, warping, or leaking.

Manufacturers typically use high-strength metals like brass, stainless steel, or aluminum alloys for the housing and shaft. These materials offer excellent resistance to the forces exerted by high-pressure water. Ensuring that the joint remains intact even under the most demanding conditions. Additionally, the seals are specially formulated to maintain their integrity under high pressure. Preventing leaks that could reduce cleaning efficiency or damage other components.

Durability and Resistance to Wear

High-pressure car washing machines are workhorses, often operating for hours on end every day. This means that the rotating joint must be able to withstand constant use without succumbing to wear and tear. The friction generated by the rotating shaft against the seals can cause gradual degradation over time, but special rotating joints are designed to minimize this issue.

Many models feature self-lubricating seals or bearings that reduce friction, extending the life of the joint. The materials used in the seals are also chosen for their wear resistance—polyurethane, for example, is known for its ability to withstand repeated contact without breaking down. Additionally, the housing and shaft are often treated with corrosion-resistant coatings to protect against rust and damage from water, soap, and other cleaning chemicals used in car washes.

Smooth Rotation and Flexibility

To ensure that the rotating components (brushes, nozzles, arms) can move freely and cover all areas of the vehicle, the rotating joint must allow for smooth, unobstructed rotation. This is achieved through precision machining of the shaft and housing, which ensures a tight fit between the parts without excessive friction.

Some rotating joints are designed to swivel or pivot, allowing for greater flexibility in the movement of the cleaning tools. This is particularly useful in mobile car wash systems, where the operator may need to adjust the angle of the nozzle to reach hard-to-clean areas. The ability to rotate 360 degrees or pivot at various angles ensures that the high-pressure water can reach every nook and cranny of the vehicle, from the wheel wells to the undercarriage.

Compatibility with Cleaning Chemicals

Car washes don’t just use water—they often incorporate detergents, waxes, and other cleaning chemicals to enhance the cleaning process. These chemicals can be harsh, and over time, they can degrade certain materials. Special rotating joints for high-pressure car washing machines are designed to be compatible with these chemicals, ensuring that they don’t corrode the housing, shaft, or seals.

Seals made from nitrile rubber or PTFE are particularly resistant to chemicals, making them a popular choice for car wash applications. The metal components may also be treated with chemical-resistant coatings or made from stainless steel, which is naturally resistant to corrosion from most cleaning agents. This compatibility ensures that the rotating joint remains functional and reliable even after prolonged exposure to harsh chemicals.

Benefits of Using Special Rotating Joints in High-Pressure Car Washing Machines

Investing in a high-quality special rotating joint for a high-pressure car washing machine offers a range of benefits that can improve the efficiency, performance, and longevity of the system. Here are some of the key advantages:

Consistent Water Pressure and Cleaning Performance

A reliable rotating joint ensures that the high-pressure water flows continuously to the rotating components without pressure loss. This consistency is crucial for achieving uniform cleaning results—every part of the vehicle receives the same level of pressure, ensuring that dirt and grime are removed evenly. In contrast, a faulty or low-quality rotating joint may leak, causing pressure drops that result in uneven cleaning, with some areas left dirty while others are blasted with too much pressure (which can damage the vehicle’s paint or finish).

Reduced Downtime and Maintenance Costs

Special rotating joints are designed to be durable and long-lasting, reducing the need for frequent replacements. Their resistance to wear, corrosion, and chemical damage means that they can withstand the rigors of daily use in a car wash environment, minimizing downtime due to breakdowns. Additionally, many high-quality rotating joints are easy to maintain—some feature replaceable seals, allowing operators to quickly repair the joint rather than replacing the entire unit. This can save time and money on maintenance, keeping the car wash running smoothly.

Energy and Water Efficiency

Leaks in the rotating joint can waste large amounts of water and energy. Every drop of water that leaks from the joint is water that isn’t being used to clean the vehicle, requiring the pump to work harder to maintain pressure and increasing water consumption. A tight-sealing special rotating joint prevents these leaks, ensuring that all the water and energy used by the machine goes toward cleaning the vehicle. This not only reduces operating costs but also makes the car wash more environmentally friendly, as it uses fewer resources.

Protection for the Vehicle and Machine

A well-functioning rotating joint helps protect both the vehicle being cleaned and the car wash machine itself. Maintaining consistent pressure prevents excessive pressure from damaging the vehicle’s paint, trim, or windows. It also reduces the strain on other components of the machine, such as the pump and hoses, by ensuring that pressure is distributed evenly throughout the system. This can extend the life of the entire machine, reducing the need for costly repairs or replacements.

Applications of Special Rotating Joints in Different Types of High-Pressure Car Washing Machines

Special rotating joints are used in a variety of high-pressure car washing machines, each with its unique requirements. Here’s how they are applied in different types of systems:

In-Bay Automatic Car Washes

In-bay automatic car washes are popular in commercial settings, where vehicles drive into a bay and are cleaned by a series of rotating brushes, spray nozzles, and dryers. These systems often feature a rotating top brush that cleans the vehicle’s roof and hood, as well as side brushes that clean the doors and fenders.

Special rotating joints are used to connect the high-pressure water supply to these rotating brushes. The joints must allow the brushes to spin freely while maintaining a tight seal, ensuring that water is delivered to the brushes at high pressure. In some systems, rotating joints are also used in the spray arms that deliver pre-wash detergents and rinse water, allowing the arms to pivot and reach all surfaces of the vehicle.

Tunnel Car Washes

Tunnel car washes are even more automated, with vehicles being pulled through a tunnel by a conveyor belt while being cleaned by a series of stationary and rotating tools. These systems often use high-pressure spray nozzles mounted on rotating arms that spin around the vehicle, as well as oscillating brushes that move back and forth.

Rotating joints in tunnel car washes must be able to handle continuous, high-speed rotation for hours at a time. They are used in the rotating spray arms to deliver high-pressure water and chemicals, ensuring that the vehicle is cleaned thoroughly as it moves through the tunnel. The durability and high-pressure resistance of these joints are critical, as any failure could disrupt the entire operation of the tunnel.

Mobile High-Pressure Car Wash Systems

Mobile car wash services bring the cleaning power directly to the customer, using portable high-pressure machines mounted in vans or trucks. These systems are often more compact than their commercial counterparts but still require rotating components to reach all parts of the vehicle.

Special rotating joints in mobile systems are designed to be lightweight and flexible, allowing operators to maneuver the cleaning tools easily. They may be used in handheld rotating nozzles or small brush attachments, enabling the operator to clean tight spaces like wheel wells and undercarriages. The joints must also be durable enough to withstand the vibrations and movement associated with mobile use, ensuring reliable performance on the go.

Self-Service Car Washes

Self-service car washes allow customers to clean their vehicles using high-pressure hoses mounted on posts. While these systems are less automated, some feature rotating brushes or spray wands that customers can use to clean their vehicles more effectively.

Rotating joints in self-service car washes are designed to be user-friendly and durable, withstanding the occasional rough handling by customers. They ensure that the high-pressure water flows smoothly to the rotating brushes or wands, making it easy for customers to achieve professional-quality results.

How to Choose the Right Special Rotating Joint for Your High-Pressure Car Washing Machine

Selecting the right rotating joint for your high-pressure car washing machine is essential to ensuring optimal performance and longevity. Here are some factors to consider when making your choice:

Pressure Rating

The first and most important factor is the pressure rating of the rotating joint. It must be able to handle the maximum pressure of your car washing machine. If your machine operates at 3,000 PSI, choose a rotating joint with a pressure rating of at least 3,000 PSI—preferably higher, to provide a safety margin. Using a joint with a lower pressure rating than your machine can lead to leaks, failures, and potentially dangerous situations.

Material Compatibility

Consider the materials used in the rotating joint, especially if your car wash uses chemicals like detergents or waxes. Ensure that the housing, shaft, and seals are compatible with these chemicals to prevent corrosion or degradation. Stainless steel housings and PTFE or nitrile rubber seals are good choices for most car wash applications, as they offer excellent chemical resistance.

Rotational Speed and Range

Different car wash systems require different rotational speeds and ranges. For example, a rotating brush may spin at a slower speed than a high-pressure spray arm. Choose a rotating joint that is designed to handle the rotational speed of your machine’s components. Additionally, consider the range of motion—some joints allow for 360-degree rotation, while others are designed to pivot at specific angles. Select a joint that matches the movement requirements of your cleaning tools.

Size and Fit

The rotating joint must fit properly with your machine’s hoses and rotating components. Measure the diameter of your supply hose and the connection point on the rotating component to ensure a proper fit. Many rotating joints come with standard thread sizes (such as 1/4 inch, 3/8 inch, or 1/2 inch), but custom sizes may be available for specialized systems. A poor fit can lead to leaks and reduced performance, so it’s important to choose the right size.

Brand Reputation and Warranty

When investing in a special rotating joint, choose a reputable brand with a proven track record in the car wash industry. Look for manufacturers that specialize in high-pressure fluid handling components, as they are more likely to produce reliable, high-quality rotating joints. Additionally, check the warranty—many reputable brands offer warranties of 1 to 5 years, which can provide peace of mind and protection against defects.

Maintenance Tips for Special Rotating Joints

Proper maintenance is key to ensuring the longevity and performance of special rotating joints in high-pressure car washing machines. Here are some tips to keep your rotating joint in top condition:

Regular Inspection

Inspect the rotating joint regularly for signs of wear, damage, or leaks. Look for cracks in the housing, corrosion, or worn seals. If you notice any leaks—even small ones—address them immediately, as they can worsen over time and lead to pressure loss or damage to other components.

Clean the Joint

Regularly clean the rotary joint to prevent the accumulation of dirt, debris, and chemical residues. Rinse the joint with clean water, and if necessary, gently wipe the sealed area with a soft-bristle brush. Avoid using harsh chemicals or abrasive cleaners, as they can damage the seals or housing.

Lubricate Moving Parts

Some rotating joints require lubrication to ensure smooth rotation. Check the manufacturer’s instructions to see if your joint needs lubrication and what type of lubricant to use. Typically, a high-pressure, water-resistant lubricant is recommended. Apply lubricant according to the manufacturer’s schedule—over-lubricating can attract dirt and debris, while under-lubricating can cause increased friction and wear.

Replace Seals When Necessary

The seals in the rotating joint are the most vulnerable components and will eventually wear out over time. Many high-quality rotating joints allow for seal replacement without replacing the entire unit. Keep replacement seals on hand and replace them as soon as you notice signs of wear (such as leaks or reduced pressure). This is a cost-effective way to extend the life of the joint.

Store Properly When Not in Use

If you have a mobile car wash system or need to store the rotating joint for an extended period, clean it thoroughly and store it in a dry, protected area. Avoid exposing it to extreme temperatures or harsh chemicals, as this can damage the seals and housing.

Common Problems and Troubleshooting

Even with proper maintenance, rotating joints can occasionally experience problems. Here are some common issues and how to troubleshoot them:

Leaks

Leaks are the most common problem with rotating joints. They can be caused by worn seals, damaged housing, or a loose connection. First, check to ensure that the joint is properly tightened. If the leak persists, inspect the seals for wear—if they are cracked or worn, replace them. If the housing is damaged (cracked or warped), the entire joint may need to be replaced.

Reduced Pressure

Reduced water pressure can be caused by a partially clogged rotating joint, worn seals, or a damaged shaft. Check for debris in the internal channels and clean the joint if necessary. If the seals are worn, replace them. If the shaft is damaged, it may cause restrictions in the water flow, requiring the joint to be replaced.

Rough or Noisy Rotation

Rough or noisy rotation is often a sign of worn bearings or insufficient lubrication. Check the bearings for wear and replace them if necessary. Apply lubricant according to the manufacturer’s instructions to see if it resolves the issue. If the problem persists, the joint may be misaligned or damaged, requiring professional repair or replacement.

Corrosion

Corrosion can occur if the rotating joint is exposed to harsh chemicals or is not properly maintained. If you notice corrosion on the housing or shaft, clean the affected area and apply a corrosion-resistant coating if possible. If the corrosion is severe, the joint may need to be replaced to prevent leaks or failure.

Conclusion

Special rotating joints may be small in size, but they play a huge role in the performance and efficiency of the system.