Boost Performance with Compact Swivel Joint: A Complete Guide for Engineers

In the intricate landscape of mechanical engineering and industrial equipment, compact swivel joint stands as essential components that play a pivotal role in enabling seamless operations across diverse sectors. In today’s fast-paced industrial landscape, engineers and procurement specialists are constantly seeking ways to optimize fluid transfer systems while saving space and minimizing maintenance. This is where Compact Swivel Joints come into play.

Compact swivel joints—also known as compact rotary unions or swivel couplings—are pivotal components in systems where rotational motion and fluid or air transfer must co-occur. Whether it’s hydraulic equipment, pneumatic systems, or cooling machinery, these space-saving devices boost efficiency, reliability, and equipment lifespan.

In this guide, we’ll cover everything engineers, technicians, and procurement teams need to know about compact swivel joints: from their design and applications to selection criteria, installation tips, and maintenance best practices.

Defining the Compact Swivel Joint

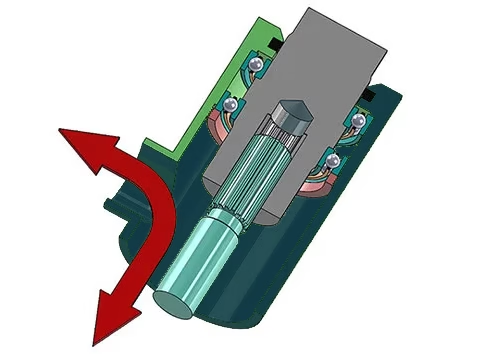

Engineers design compact swivel joints as specialized mechanical devices that enable two or more components to rotate relative to each other while maintaining a secure pathway for the transfer of fluids, gases, or electrical signals. Their defining feature is a space-efficient design, enabling installation in tight environments where traditional swivel joints would prove impractical. These joints excel in applications where space optimization is critical, such as aerospace, medical devices, and precision machinery.

A typical compact swivel joint comprises two main parts: a stationary housing attached to fixed structures or pipelines and a rotating element that pivots around an axis.

Key internal components include:

Housing:

A durable outer shell protects internal mechanisms, often crafted from stainless steel, alloy steel, or high-performance polymers.

Rotating Element:

Equipped with bearings (ball, roller, or plain) to minimize friction during movement.

Seals:

Critical components preventing leakage are made from materials like Viton or PTFE to suit specific fluid types and operating conditions.

Core Purposes of Compact Swivel Joint

1. Enabling Rotational Movement in Tight Spaces

One of the primary functions of a compact swivel joint is to facilitate smooth rotation in confined areas. In industrial and commercial settings, equipment often has limited space for moving parts, making traditional joints unsuitable. These compact solutions allow components to pivot and turn without occupying excessive room, ensuring machinery can operate efficiently in restricted environments.

Aerospace Applications

In aircraft, where every inch of space is optimized, compact swivel joint plays a vital role in fuel, hydraulic, and avionics systems. For example, they enable fuel lines, hydraulic hoses, and control cables to rotate within the tight compartments of wings and fuselages. This ensures seamless movement of components like landing gear and flight control surfaces while maintaining secure fluid and signal transfer.

Medical Devices

In robotic surgical equipment, space constraints are extreme. Compact swivel joint allows robotic arms to rotate and maneuver with precision inside the human body, enabling minimally invasive surgeries. Their small size ensures surgical instruments can reach delicate areas without damaging tissues, supporting complex procedures like laparoscopic surgeries.

2. Facilitating Fluid and Gas Transfer

Compact swivel joints excel in maintaining a continuous, leak-proof flow of fluids and gases between stationary and rotating system parts. Whether transferring hydraulic oil, compressed air, or food-grade liquids, these joints ensure reliability in demanding environments.

Automotive Systems

In automotive power steering, compact swivel joints connect the steering column to hydraulic lines, allowing smooth rotation while transmitting the fluid needed for easy steering. Similarly, braking systems enable brake fluid transfer between the master cylinder and calipers as wheels turn, ensuring consistent braking performance.

Food and Beverage Industry

Hygiene and precision are paramount in food processing. Compact swivel joints in mixers, fillers, and packaging machines transfer liquids and gases between components, such as connecting filling nozzles to supply lines in bottling plants. Their design with food-grade materials and easy-to-clean surfaces prevents contamination, meeting strict industry standards.

3. Reducing Stress and Wear on Connected Components

By allowing rotational movement, compact swivel joints distribute mechanical forces evenly, reducing stress on hoses, pipes, and fittings. This extends the lifespan of connected components and minimizes maintenance needs.

Industrial Machinery

In printing presses, constant vibration and movement can wear down hoses. Compact swivel joints absorb forces generated by rotating cylinders, protecting ink supply lines from excessive bending and twisting. This reduces leaks and downtime, ensuring reliable operation.

Mobile Equipment

Construction cranes and forklifts rely on hydraulic systems with moving booms and forks. Compact swivel joint allows hydraulic hoses to move freely, reducing stress on fittings and minimizing the risk of fluid leaks—a critical safety and cost-saving feature in heavy applications.

4. Enhancing System Flexibility and Adaptability

Compact swivel joints improve the versatility of mechanical systems by enabling easy reconfiguration of component positions without complex rewiring or replumbing.

Modular Furniture and Renewable Energy

In modular furniture, these joints connect legs and panels, allowing easy assembly, disassembly, and reconfiguration to suit different spaces. In wind turbines, they enable nacelles to rotate into the wind (yaw systems) and adjust blade angles (pitch control), maximizing energy capture while maintaining electrical and hydraulic connections.

Key Applications Across Industries

Aerospace Industry

Fuel Systems:

Connect fuel tanks to engines in aircraft, ensuring leak-free fuel transfer during maneuvers.

Hydraulic/Pneumatic Systems:

Enable movement of landing gear, flight controls, and brakes by transferring fluids and air in tight compartments.

Avionics:

Facilitate rotation of radar antennas and communication dishes, maintaining electrical connections for navigation and surveillance.

Medical Equipment

Robotic Surgery:

Provide precise movement for robotic arms in minimally invasive procedures, enhancing surgical accuracy.

Diagnostic Tools:

Position patient tables and imaging coils in MRI/CT scanners for accurate scans.

Patient Monitoring:

Allow adjustable positioning of infusion pumps and ventilators for patient comfort and care.

Automotive Industry

Power Steering:

Ensure smooth hydraulic fluid flow during steering column rotation.

Braking Systems:

Maintain brake fluid transfer as wheels and suspension move.

Suspension:

Connect shock absorbers, improving ride quality by allowing wheel movement over uneven terrain.

Food and Beverage Industry

Processing Equipment:

Transfer ingredients into mixers and blenders, ensuring hygienic and efficient operation.

Packaging Machinery:

Connect conveyor belts and filling nozzles in bottling and canning lines for accurate product handling.

Renewable Energy

Wind Turbines:

Enable nacelle rotation and blade angle adjustment for optimal energy production.

Solar Systems:

Support solar panel tracking to follow the sun, maximizing energy capture with lightweight, compact designs.

Benefits of Compact Swivel Joints

Space-Saving Design

Their small size allows installation in confined areas, critical for industries like aerospace and medical devices, where space is limited. This design also reduces equipment weight and manufacturing costs.

High Precision and Accuracy

Tight tolerances and quality construction ensure precise rotational movement, essential for applications requiring exact positioning, such as robotic surgery and aerospace navigation.

Durability and Longevity

Built from high-quality materials like stainless steel and advanced polymers, these joints withstand high pressure, temperature, and mechanical stress, reducing maintenance and replacement needs.

Versatility

Engineers can customize compact swivel joints for diverse applications, including varying pressure/temperature ratings, fluid compatibility, and rotational speeds, making them a flexible choice across industries.

Improved System Performance

By enabling smooth movement and reducing component stress, these joints enhance equipment reliability, reduce downtime, and boost productivity in critical operations.

Factors to Consider When Selecting Compact Swivel Joints

Operating Conditions

Pressure/Temperature Ratings:

Match the joint’s specifications to the system’s maximum pressure (e.g., 15,000 psi for offshore drilling) and temperature (e.g., -40°C to 200°C for industrial use).

Fluid/Gas Compatibility:

Choose seals and materials resistant to the transferred medium (e.g., stainless steel for corrosive fluids, PTFE for chemical resistance).

Environmental Factors:

Select joints with protective coatings or enhanced seals for harsh environments (e.g., marine applications with saltwater exposure).

Mechanical Requirements

Load Capacity:

Ensure the joint can support the weight or force of connected components to avoid premature wear.

Rotational Speed:

Opt for high-speed bearings (e.g., ceramic ball bearings) for applications requiring rapid rotation, such as industrial machinery.

Range of Motion:

Choose between 360° rotation or limited movement based on the application’s needs (e.g., full rotation for robotic arms, articulation for medical devices).

Material Selection

Metals:

Stainless steel (corrosion resistance), alloy steel (high strength), or carbon steel (cost-effectiveness for non-corrosive environments).

Polymers:

Lightweight options like PEEK or PTFE for low-pressure, high-purity applications (e.g., medical or food industries).

Installation and Maintenance Best Practices

Installation Guidelines

Cleanliness:

Remove debris from mating surfaces to prevent seal damage and leaks.

Alignment:

Use precision tools to ensure proper axis alignment, minimizing angular misalignment that causes excessive friction. Torque Control: Follow the manufacturer’s specs when tightening bolts to avoid housing deformation.

Maintenance Tips

Regular Inspections:

Check for wear, leaks, or corrosion during routine maintenance, especially in high-stress environments.

Lubrication: Apply compatible lubricants (e.g., silicone grease for fluorocarbon seals) to reduce friction and extend bearing life.

Troubleshooting:

Address issues promptly—replace worn seals for leaks, check bearing condition for excessive vibration, and verify alignment for misalignment-related noise.

FAQs About Compact Swivel Joints

Q1: What are the primary applications of compact swivel joints, and how do they differ from traditional swivel joints?

Compact swivel joints are designed for applications where space is limited, and efficient use of space is critical. They are commonly used in industries such as aerospace, medical devices, automotive, and food and beverage processing. Unlike traditional swivel joints, which are often larger and bulkier, compact swivel joints offer a space-saving design without compromising performance. They facilitate rotational movement, fluid transfer, and connection between components in tight spaces, making them ideal for applications where traditional joints may not fit.

Q2: How do compact swivel joints contribute to the overall performance and efficiency of mechanical systems?

Compact swivel joints significantly enhance the performance and efficiency of mechanical systems by enabling smooth rotational movement, facilitating fluid transfer, and reducing stress on connected components. They help to distribute mechanical forces evenly, preventing excessive wear and tear on hoses, pipes, and other parts of the system. This results in improved system reliability, reduced downtime, and enhanced productivity. Additionally, their high precision and accuracy make them suitable for applications requiring precise positioning and control, such as robotic surgery and aerospace navigation.

Q3: What factors should be considered when selecting and maintaining compact swivel joints to ensure optimal performance and longevity?

When selecting compact swivel joints, several factors should be considered, including operating conditions (pressure, temperature, fluid or gas type, and environmental conditions), mechanical requirements (load capacity, rotational speed, and range of motion), and material selection. It is crucial to choose a joint that is compatible with the specific application requirements.

For maintenance, regular inspection, lubrication, and troubleshooting are essential. This includes checking for visible wear, leaks, or corrosion during routine maintenance cycles, replenishing lubricant according to the operating environment, and addressing issues such as low pressure, excessive vibration, or leakage promptly. By following these best practices, the lifespan of compact swivel joints can be maximized, ensuring optimal performance and longevity.

Conclusion

Compact swivel joints are indispensable in modern engineering, offering a unique blend of space efficiency, reliability, and versatility. By understanding their technical specifications, industry applications, and maintenance requirements, engineers can optimize system design for performance and longevity. Whether you’re designing a new machine or upgrading an aging system, the compact swivel joint is a small yet powerful component that can make a big impact on performance, reliability, and efficiency.

As industries continue to demand more compact and efficient solutions, these joints will remain critical in enabling innovation across aerospace, healthcare, energy, and beyond. Whether facilitating precision surgery or maximizing renewable energy capture, compact swivel joints prove that big functionality can come in small packages. By selecting the right model for your application, following proper installation protocols, and conducting regular maintenance, engineers and procurement teams can extend system life and boost operational performance.