How does a rotary joint work?

Rotary joints, also known as rotary unions or swivel joints, are pivotal components in industrial machinery, enabling the transfer of fluids (liquids, gases, or steam) between stationary and rotating parts. These devices ensure leak-free operation under extreme pressures, temperatures, and rotational speeds, making them indispensable in sectors like manufacturing, aerospace, and renewable energy.

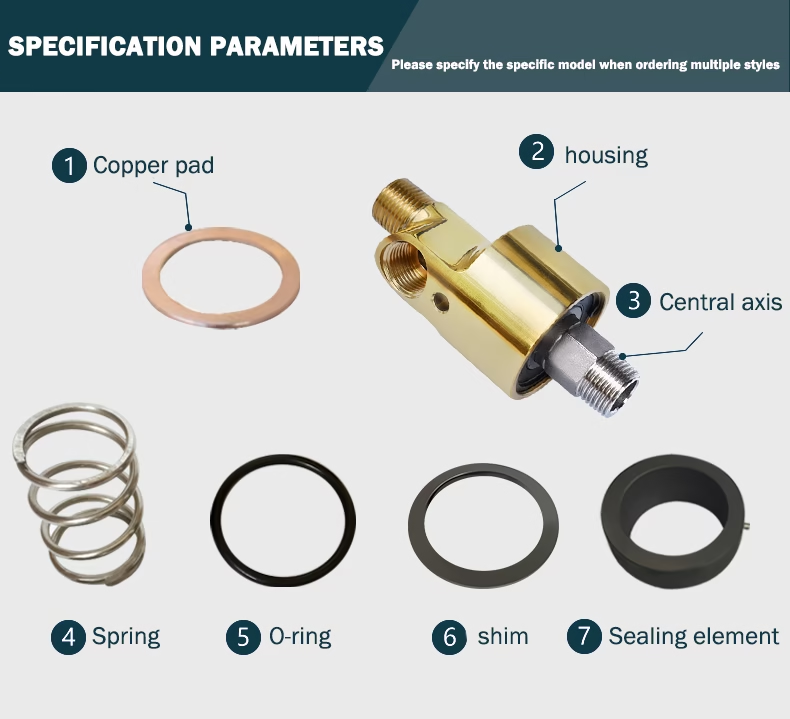

Core Components of a Rotary Joint

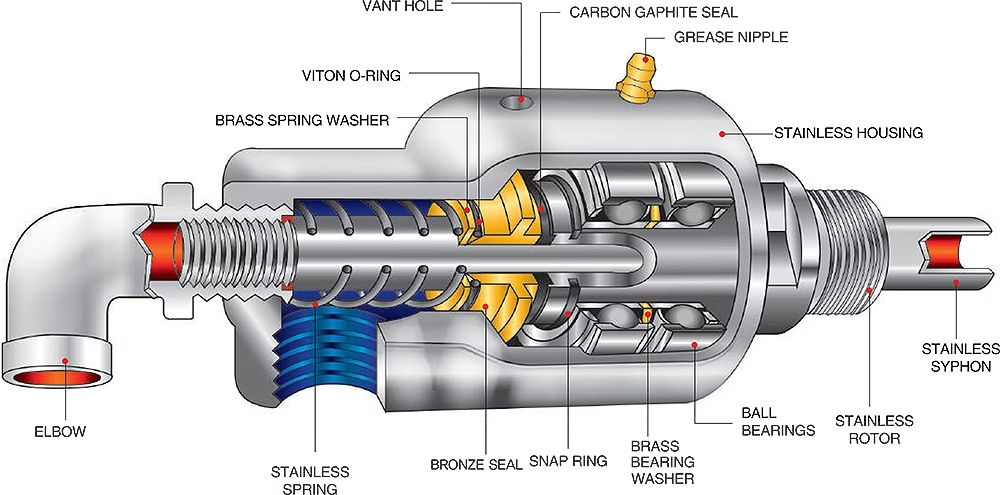

A rotary joint consists of several critical parts that work in tandem to achieve seamless fluid transfer:

🔵 1. Rotating Shaft (Rotor)

• Connects to moving machinery parts for media transmission

• Materials: Stainless steel/brass for corrosion resistance

🟢 2. Stationary Housing (Stator)

• Fixed to the machine frame as the outer structural shell

• Encloses rotating elements for stability

⚙️ 3. Bearings

• Reduce friction during rotation

• Types: Ball bearings, roller bearings

🔒 4. Seal Assembly

• Critical leak prevention component

• Materials: Carbon-graphite, ceramic, tungsten carbide (high wear-resistance)

🔄 5. Elastic Elements

• Springs/bellows compensate for thermal expansion

• Maintain seal integrity by adjusting to wear

How Rotary Joints Work?

The rotary joint, a seemingly simple part, plays a vital role in modern industry. It is the intermediary of liquid, gas, steam, and other media in mechanical equipment. It ensures that various high-end equipment does not leak when rotating and maintains the sealing and stability of the system. How does this small Luo component accomplish such a complex task? What is so special about its working method?

How do rotary joints work? The core principle of the rotary joint is to combine rotational motion with fluid transmission. Imagine that the parts of the machine are constantly rotating, and the fluid needs to pass through these rotating parts smoothly without any leakage. The design of the rotary joint is like a bridge that establishes a stable connection between rotation and sealing. It can prevent any fluid from leaking at high speeds, thereby ensuring the efficient operation of the system.

From a structural point of view

The rotary joint is usually composed of multiple sealing rings, which fit tightly inside the joint. Their task is to ensure that the fluid does not leak when passing through the joint. The outside of the joint is usually made of wear-resistant materials, which can withstand long-term high-load operation. The seemingly simple circles of seals are a moat to prevent fluid leakage. They are not disturbed by high-speed rotation and always maintain a perfect sealing state.

The rotary joint is mainly composed of three parts: the outer sleeve, the inner sleeve, and the needle roller. The outer sleeve is a cylindrical part with a set of arc grooves inside. The inner sleeve is a cylindrical part with a set of arc bosses outside. The needle roller is a rolling element placed between the outer sleeve and the inner sleeve. When the two axes are connected, the axes of the outer sleeve and the inner sleeve will move relative to each other. In this process, the needle roller plays a key role.

When the outer sleeve and the inner sleeve rotate, the needle roller rolls between the grooves and bosses, thereby realizing the transmission of the two axes. Specifically, when the outer sleeve and the inner sleeve rotate, the needle roller will be subjected to the force between the grooves and bosses of the outer sleeve and the inner sleeve, thereby generating a rolling motion. This rolling motion transmits the torque to the inner sleeve and then to the connected axis through the inner sleeve, realizing the rotation of the axis.

Ⅰ、Influencing factors

The rotary joint uses the rolling motion of the needle roller to reduce friction resistance. The needle roller can roll between the outer sleeve and the inner sleeve, thereby reducing the contact area of friction, reducing the friction force, and making the rotation smoother.

How rotary joints work? The working principle of the rotary joint is also related to the shape of the needle roller. The needle roller is usually cylindrical and has a smooth surface, thereby reducing the contact area with the outer sleeve and the inner sleeve, further reducing the friction force. The working principle of the rotary joint is also related to the shape of the grooves and bosses of the outer sleeve and the inner sleeve. The grooves and bosses usually designed in an arc shape, so that the needle roller can roll smoothly between them, thereby realizing the transmission of torque.

How rotary joints work? The working principle of the rotary joint is also related to the selection of materials. To reduce friction and wear, the rotary joint usually made of high-strength and wear-resistant materials, such as high-speed steel, alloy steel, and other strong and durable materials.

The rotary joint is a mechanical component that realizes the transmission of the axis by rolling the needle roller between the outer sleeve and the inner sleeve. Its working principle is mainly to use the rolling motion of the needle roller and the matching of the grooves and bosses of the outer sleeve and the inner sleeve to reduce friction and realize the transmission of torque. Through reasonable design and material selection, the rotary joint can work stably and reliably in various mechanical equipment.

Ⅱ、Main Functions of the Rotary Joint

🔵 1. Relieve Pipeline Stress

Compensates for stress caused by temperature changes, pipeline expansion, and settlement.

Prevents deformation, cracking, or breakage by allowing controlled rotation within the system.

🟢 2. Compensate for Pipeline Displacement

Adjusts for displacement due to pressure and temperature variations.

Ensures the pipeline system can rotate and shift safely to maintain proper alignment and functionality.

⚙️ 3. Provide Flexibility and Reliability

Enhances system adaptability to complex working conditions and environmental changes.

Reduces maintenance costs and extends the service life of the pipeline system.

🔒 4. Reduce Vibration and Noise

Minimizes the transmission of vibration and noise caused by fluid impact.

Improves system safety and workplace comfort through its rotation and buffering functions.

✅ Key Benefit: Rotary joints improve pipeline durability, system stability, and operational safety.

Ⅲ、Specific application cases

Let’s take a look at the performance of the rotary joint in actual work through a specific application case. Taking modern high-speed trains as an example, the axles, engines, brake systems, and other components of high-speed trains require rotary joints to maintain a smooth flow of fluids. The rotary joint can ensure that these fluids can pass stably without any leakage during high-speed driving or in frequent changes, such as braking and acceleration. This precise working method ensures that the train can run efficiently and safely.

In more complex environments, the role of the rotary joint is more prominent. For example, during oil drilling, the drill bit must rotate continuously. At this time, the rotary joint becomes an indispensable component. It not only ensures the smooth delivery of drilling fluids but also works stably in strong vibration and high-temperature environments. In this case, the rotary joint must not only withstand extremely high pressure and temperature but also ensure that there is no leakage, otherwise, it will lead to the failure of drilling operations and even cause more serious accidents.

Even such high-tech products are not perfect, and the life of the rotary joint is not unlimited. With the increase in working hours, the seals of the rotary joint will gradually wear, resulting in a decrease in sealing performance. Once a leak occurs, it will not only affect the normal operation of the equipment but also may pollute the environment, so regular maintenance of the rotary joint is particularly important. Regularly replacing seals and checking the working status of the joint can extend its service life and reduce the possibility of failure.

Key Considerations for Seals

🔵 1. Pressure Resistance

Seals must be able to withstand the operating pressure of the system without deforming or failing.

🟢 2. Temperature Resistance

Materials used for seals should be compatible with the temperature range of the fluid and the environment.

⚙️ 3. Friction Management

Low-friction materials and designs help reduce wear and improve the efficiency of the rotary joint.

• Wear Resistance: Seals should be durable and resistant to wear to ensure long-term performance and reliability.

Maintenance and Inspection

• Regular Inspections: Check for signs of wear, leaks, or misalignment. Inspect seals, bearings, and the housing for any damage.

• Lubrication: Ensure that bearings and seals are properly lubricated to reduce friction and wear.

• Replacement: Replace worn or damaged components promptly to prevent further issues and ensure the continued performance of the rotary joint.

The working principle of a rotary joint revolves around maintaining a sealed connection between stationary and rotating parts, ensuring the efficient transfer of fluids or gases without leakage. By utilizing advanced sealing technologies and precision engineering. Rotary joints provide reliable performance in various industrial applications, from cooling systems to hydraulic circuits and beyond.

Conclusion

Rotary joints are the backbone of modern industrial systems, enabling efficient fluid transfer in the most demanding environments. By understanding their mechanics, selecting the right type, and adhering to maintenance protocols, industries can achieve higher efficiency and reduced downtime. Innovations like smart sensors and hybrid designs continue to push the boundaries of reliability and performance. For more details, view it.

If u have any query, kindly contact us via email: dannhydraulic@gmail.com.