How does a water rotary union work?

In the complex world of industrial machinery, there is a small but critical hero that often goes unnoticed: the rotary union. Specifically, when it comes to cooling or heating rotating equipment, the water rotary union is an indispensable component. Water rotary unions, also known as rotary joints or swivel joints, are critical components in machinery requiring the transfer of water, steam, or other fluids between stationary and rotating parts. These devices are widely used in industries such as manufacturing, energy, aerospace, and chemical processing. They represent a fascinating intersection of mechanical engineering and fluid dynamics, serving as critical components in countless industrial applications worldwide. These specialized devices enable the seamless transfer of water and other fluids between stationary and rotating components without leakage, making them indispensable in manufacturing processes, cooling systems, and various machinery. This comprehensive guide explores the intricate Water rotary union Working principle, its components, applications, and best practices for implementation and maintenance.

If you have ever wondered how water moves from a stationary pipe into a spinning roller without leaking, you are in the right place. In this extensive guide, we will dissect the working principle of a water rotary union, its anatomy, types, and best practices for maintenance.

Understanding Rotary Unions: Basic Concepts and Definitions

What is a Water Rotary Union?

A water rotary union is a precision-engineered mechanical device that enables the continuous transfer of water, steam, or other fluids from a stationary supply line to a rotating component. Also known as rotating unions, rotary joints, or swivel joints, these devices effectively solve the fundamental challenge of transferring fluids to moving parts without causing interruption or damage to the supply lines.

To understand the concept more intuitively, imagine connecting a garden hose to a spinning drum. Without a rotary union, the hose would twist, potentially causing damage or restricting flow. A rotary union elegantly solves this problem by creating a sealed connection that allows water to flow freely while accommodating rotation.

The Importance of Rotary Unions in Industrial Applications

Rotary unions serve as critical components in numerous industrial settings where the transfer of fluids to rotating equipment is essential. Their ability to maintain leak-free connections while supporting continuous rotation makes them vital in applications ranging from manufacturing processes to cooling systems.

The quality of a rotary union is primarily judged by its leak-tightness—the ability to prevent fluids from escaping between stationary and rotating parts. A leak would lead to significant performance loss or, in worst-case scenarios, complete machine failure, resulting in costly downtime and repairs. Additionally, modern rotary unions are designed for longevity and reliability, with some capable of operating at speeds up to 100,000 revolutions per minute.

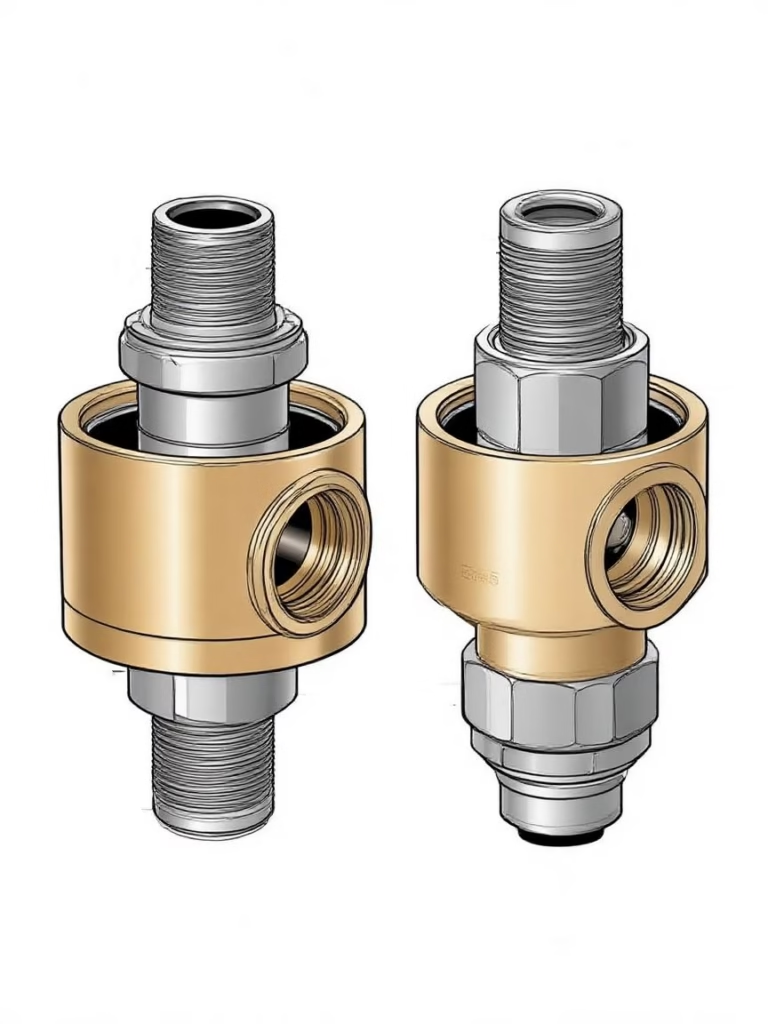

The Anatomy of a Rotary Union

To understand the working principle, we must first understand the architecture. While designs vary based on pressure, speed, and temperature, most high-quality water rotary unions share these core components:

1. The Housing (Stationary Body)

The housing is the outer shell that holds the unit together. It connects to the stationary supply lines (the inlet and outlet hoses) and does not rotate. It is usually made from brass, aluminum, or stainless steel to resist corrosion.

2. The Shaft (Rotating Rotor)

The shaft is the component that attaches to the machine. It rotates at the same speed as the equipment. The shaft is usually hollow, allowing the water to pass through it and into the machine’s roller or spindle.

3. The Bearing Assembly

Bearings are crucial for supporting the rotating shaft within the stationary housing. They ensure smooth rotation and low friction. Perhaps most importantly, they keep the shaft perfectly aligned. Even a microscopic misalignment can cause the internal seals to fail. High-speed unions often use precision ceramic or angular contact bearings.

4. The Mechanical Seal (The Heart of the Union)

This is where the magic happens. The mechanical seal prevents water from leaking out where the rotating shaft meets the stationary housing.

- Stationary Ring: Held in the housing.

- Rotating Ring: Attached to the shaft. These two faces are lapped to optical flatness (measured in light bands). They glide against each other, creating a dynamic seal. Common materials include Silicon Carbide, Tungsten Carbide, or Carbon Graphite.

5. The Spring

A spring (or series of springs) provides the initial axial force to push the stationary seal face against the rotating seal face. This ensures that even when the water pressure is off, the seal remains tight.

The Water rotary union Working principle

Now, let’s dive into the core of this article: the Water rotary union Working principle. How does it actually function under pressure and speed?

The working principle relies on a balance of hydraulic force, spring force, and precision tribology (the science of friction and lubrication).

Step 1: Connection and Inflow

The process begins with the stationary housing connected to a water supply. Water enters the housing through an inlet port. At this stage, the machine is turned on, and the shaft (connected to the application) begins to spin.

Step 2: The Dynamic Seal

As the water enters the union, it travels toward the interface between the stationary and rotating parts. This is the critical point.

- The Spring Force: The internal spring pushes the stationary seal face against the rotating seal face. This keeps the joint closed when there is no water pressure.

- The Hydraulic Force: As water pressure builds, the fluid itself pushes against the back of the seal, increasing the closing force. This creates a tighter seal as pressure rises.

Step 3: The Micro-Film Lubrication

You might ask: If two surfaces are rubbing against each other at 5,000 RPM, why don’t they burn up? The answer is the fluid film. The faces of the mechanical seals are not perfectly smooth at a microscopic level. The water seeps slightly between the two seal faces, creating a hydrodynamic film that is only microns thick. This film lubricates the seals, reducing friction and heat generation. Essentially, the seals are “hydroplaning” on a microscopic layer of water. If this film is lost (dry running), the seal faces will touch, overheat, and shatter.

Step 4: Circulation and Outflow

The water passes through the hollow shaft and into the machinery (e.g., a cooling roller).

- In a Single-Flow system, the water enters the roller, cools it, and exits the other side of the roller (using a separate union).

- In a Dual-Flow (Duoflow) system, the water enters through an inner tube, travels to the end of the roller, creates a return path, and travels back out through the same union (between the inner tube and the outer shaft) to the outlet port on the housing.

Types of Water Rotary Unions and Their Specifications

There are several types of water rotary unions available in the market, each tailored to suit specific applications and meet the demands of various industries. The key differences lie in the number of flow channels, design variations, and integrated functionalities.

Single-channel rotary unions

Single-channel rotary unions consist of a single fluid passage. They are the simplest and most common type, designed to handle straightforward fluid transfer applications that require the movement of water or another fluid type between stationary and rotating components. It features one fluid pathway and is ideal for simpler applications requiring the transfer of a single medium. These units tend to be more compact and cost-effective for basic applications.

Dual-Flow Rotary Unions

Dual-flow rotary unions incorporate two separate fluid passages. They allow two distinct liquids to flow simultaneously through different channels within the union, effectively isolating the streams and preventing cross-contamination. This design is ideal for applications that necessitate the transfer of multiple fluids at once, such as when supplying both coolant and cutting fluid to a machine tool during operation.

Multi-channel rotary unions

They provide multiple independent flow passages to manage different fluids within complex systems. This capability becomes advantageous in applications where different media, such as water, steam, or oil, need to be transmitted independently through the same rotary joint.

Primary Functions and Applications of Water Rotary Unions

Key Functions

Water rotary unions perform several critical functions in industrial applications:

Fluid Transfer: They convey water from a stationary source to a conducting point within a rotating structure, essential for cooling systems where water must flow through various rotating machine parts to maintain proper operating temperatures.

Sealing and Leak Prevention: Using advanced sealing technologies, rotary unions prevent water leakage between stationary and rotating sections, even under high pressures and temperatures.

Accommodating Multiple Flow Channels: Advanced rotary unions can incorporate multiple independent flow passages to manage different fluids in complex systems—particularly valuable when various fluids like water, steam, or oil must be transmitted independently.

Supporting High-Pressure Applications: Specialized water rotary unions can handle pressures reaching several thousand PSI and significant rotational speeds, making them suitable for demanding industrial environments.

Reducing Maintenance Requirements: Contemporary rotary unions feature durable construction and simplified maintenance procedures, reducing downtime and operational costs.

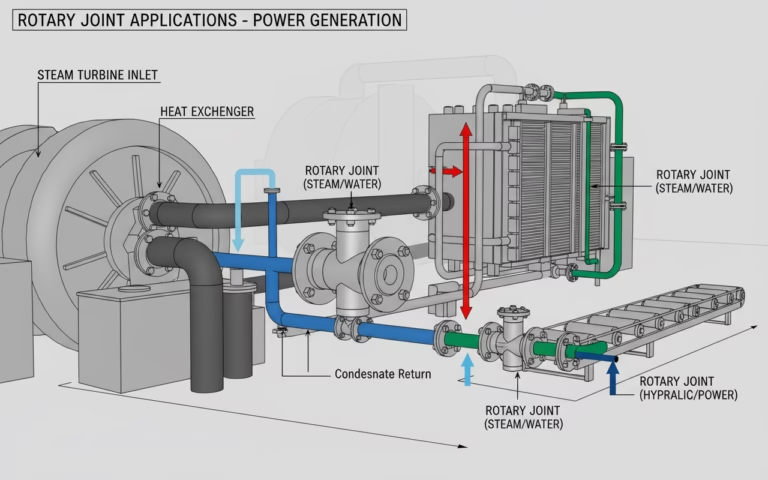

Industrial Applications

Water rotary unions are indispensable in:

Manufacturing: Coolant delivery in CNC machines.

Energy: Hydraulic systems in wind turbines.

Aerospace: Fuel and coolant transfer in jet engines.

Chemical Processing: Safe transfer of corrosive fluids.

Food & Beverage: Steam cleaning and sterilization.

Performance Characteristics and Design Considerations

Sealing Efficiency

The sealing mechanism represents the most critical aspect of a water rotary union’s performance. High-quality units maintain complete leak-tightness under varying conditions, preventing fluid loss and ensuring consistent operation. Engineers must consider factors such as pressure, temperature, media characteristics, and rotational speed when designing or selecting appropriate seal technologies.

Durability Factors

Several factors influence the longevity and reliability of water rotary unions:

Material selection: Corrosion-resistant materials like stainless steel are essential for water applications.

Bearing quality: Precision bearings reduce wear and maintain proper alignment throughout the device’s lifespan.

Seal design: Advanced seal technologies maximize sealing efficiency while minimizing friction and wear.

Manufacturing precision: Tight tolerances and proper alignment of all components ensure smooth operation and minimize premature failure.

Pressure and Speed Limitations

Every water rotary union has specific operational limits regarding pressure handling and rotational speed. These limitations vary based on design, size, and intended application.

Standard industrial water rotary unions typically operate in the 0-300 RPM range, though specialized units can achieve much higher speeds. Pressure ratings likewise vary significantly, with some high-performance units capable of handling up to 1300 bar (20,000 psi).

Engineers must carefully match the rotary union’s capabilities to the application requirements, as exceeding these limits can result in premature failure, leakage, or catastrophic damage.

Installation and Maintenance Best Practices

Proper Installation Procedures

Correct installation is essential for optimal rotary union performance:

Alignment: Ensure precise alignment between the rotary union and the rotating equipment to prevent premature seal wear and failure.

Connection integrity: Use appropriate fittings and torque specifications when connecting fluid lines to prevent leaks and ensure proper sealing.

Rotation direction: Some rotary unions are designed for specific rotation directions—verify compatibility with your application.

Environmental protection: Install protective covers or shields in harsh environments to prevent contamination and damage to exposed components.

Maintenance Requirements

Regular maintenance extends the service life of water rotary unions and prevents unexpected failures:

Routine inspection: Check for signs of leakage, unusual noise, or excessive vibration during operation.

Seal replacement: Replace seals according to manufacturer recommendations or when signs of wear become apparent.

Lubrication: Maintain proper lubrication of bearings and other moving components as specified by the manufacturer.

Cleaning: Periodically clean inlet filters and remove any accumulated debris that could restrict flow or damage internal components.

Troubleshooting Common Issues

Leak Detection and Resolution

Leakage represents the most common issue with water rotary unions. When leaks occur:

Identify the source: Determine whether leakage is occurring at connections, through the seal, or elsewhere in the system.

Check operating conditions: Verify that pressure, temperature, and speed remain within the rotary union’s specified limits.

Inspect seals: Look for wear, damage, or contamination of sealing surfaces.

Replace components: When necessary, replace worn seals, bearings, or other damaged components according to manufacturer guidelines.

Performance Degradation

Declining performance may manifest as reduced flow, inconsistent pressure, or increased operating temperature. Troubleshooting steps include:

Flow verification: Measure and compare current flow rates to baseline performance.

Pressure testing: Check pressure at the inlet and outlet to identify potential restrictions.

Alignment verification: Ensure proper alignment between the rotary union and connected equipment.

Internal inspection: When possible, disassemble and inspect internal components for wear or damage.

Selecting the Right Water Rotary Union for Your Application

Critical Selection Factors

Choosing the appropriate water rotary union requires consideration of several key factors:

Media type: While designed primarily for water, rotary unions may need to handle other fluids or media types.

Flow requirements: Consider the volume and pressure requirements of your specific application.

Rotational speed: Match the rotary union’s speed rating to your equipment’s operational parameters.

Environmental conditions: Consider temperature extremes, exposure to contaminants, and other environmental factors.

Mounting configuration: Select the appropriate mounting style (threaded, flanged, etc.) for your equipment.

Space constraints: Consider the available installation space and choose a rotary union with appropriate dimensions.

Maintenance accessibility: Ensure the selected model allows for necessary maintenance and seal replacement.

Future Trends in Water Rotary Union Technology

The water rotary union industry continues to evolve with several notable trends:

Composite materials: Development of advanced composites with enhanced durability and temperature resistance.

Miniaturization: Creation of increasingly compact designs for space-constrained applications.

Integrated monitoring: Implementation of sensors and monitoring systems to provide real-time performance data and predictive maintenance capabilities.

Enhanced sealing technologies: Development of new seal designs that offer improved durability and reduced friction.

Conclusion: The Continuing Importance of Water Rotary Unions

Water rotary unions are engineering marvels that enable seamless fluid transfer in rotating systems. From basic single-passage designs to advanced multi-channel units, their functionality is vital across industries. Water rotary unions represent a critical enabling technology in countless industrial applications, providing the essential function of transferring fluids between stationary and rotating components without leakage. Their precision engineering and specialized design ensure reliable operation in demanding environments, supporting everything from basic manufacturing processes to advanced technological applications.

As industrial technology continues to advance, water rotary unions will likewise evolve to meet new challenges—incorporating new materials, enhanced designs, and improved performance characteristics. Understanding the fundamental principles, components, and applications of these devices provides valuable insight for engineers, maintenance professionals, and industrial planners seeking to optimize fluid transfer in rotating machinery.

Whether in cooling systems, manufacturing equipment, or specialized industrial applications, water rotary unions will remain an indispensable component in the seamless operation of modern machinery, enabling the efficient and reliable transfer of water and other vital fluids throughout rotating systems.