Continuous Casting Machine Stainless Steel Rotary Union

Original price was: $50.00.$42.00Current price is: $42.00.

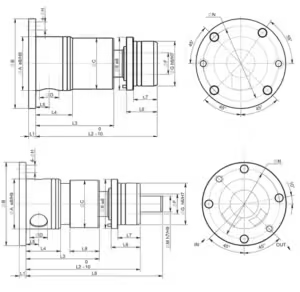

- Model: Embedded rotary joint for continuous casting machine

- Size: Customized Size

- Max.Speed: 60RPM

- Max. Pressure: 1.2mpa

- Max. Temperature: 120 degrees

- Applicable medium: Water, coolant

Description

Continuous Casting Machine Stainless Steel Rotary Union Details

The Stainless Steel Continuous Casting Machine Rotary Union is an essential component designed to facilitate the efficient transfer of cooling water in continuous casting processes. Engineered for durability and high performance, this rotary union ensures optimal fluid dynamics, enhancing the productivity and reliability of casting operations in the steel industry.

This series of rotary joints is designed according to the characteristics of continuous casting machine rolls. It will penetrate most of the joint shape into the roller, and only the pipe connection elbow is exposed outside. The assembly layout of the external space is more beautiful. It is conducive to the spatial arrangement between the roller flow and the flow. The sealing structure adopts a balanced design sealing structure. In addition to the balanced sealing design, the sealing structure design of the rotary joint also changes the original axial serial type to a unique inverted internal sealing type. In this way, not only the axial length reduced, but also the shell structure is integrated, which is more conducive to the disassembly and maintenance of the joint.

| Item | Content |

|---|---|

| Applicable fluid | Coolant, Water, Air |

| Maximum pressure | 1.5MPa |

| Maximum temperature | 180℃ |

| Maximum speed | 100rpm |

Technical Specifications & Material Advantages

Technical Specifications & Material Advantages

1. Material Composition

2. Design Features

Key Features of Continuous Casting Machine Rotary Union

Robust Stainless Steel Construction

Crafted from high-grade stainless steel, this rotary union offers superior corrosion resistance and longevity, making it ideal for harsh industrial environments.

Advanced Sealing Technology

Utilizing innovative technology, this union features a unique sealing design that enhances reliability and minimizes leakage, ensuring consistent performance even under high pressure. Balanced mechanical seal Silicon carbide seal, can operate normally under harsh environment. Balanced mechanical seal, Silicon carbide seal, can operate normally under a harsh environment.

Versatile Flow Options

Available in both through-flow and dual-flow configurations, the rotary union can accommodate various operational requirements, providing flexibility in application.

Self-Supported Design

The rotary union engineered to be self-supported, simplifying installation directly onto the caster rolls while reducing space requirements.

High Performance Ratings

Max Pressure: Up to 120 PSI (8.2 bar); Max Temperature: 250°F (121°C)

Rotational Speed: Up to 5 RPM, suitable for continuous operation without compromising efficiency.

Buyer Pain Points and Solutions for Continuous Casting Machine Stainless Steel Rotary Union

1. Frequent Fluid Leakage and Seal Failure

Pain Point: Continuous casting machines operate under high pressure and temperature, causing rotary union seals to wear quickly, leading to hydraulic or cooling water leakage. Leakage results in production downtime and costly repairs.

Solution: Use rotary unions with silicon carbide balanced mechanical seals and PTFE or Viton secondary seals designed specifically for harsh continuous casting environments. These materials resist wear and maintain sealing integrity under pressure peaks and dirty water conditions, minimizing leakage risks.

2. Premature Wear Due to Harsh Operating Conditions

Pain Point: Rotary unions in continuous casting machines face abrasive, high-temperature, and corrosive conditions, accelerating wear of internal components like bearings and seals. This leads to frequent replacements and maintenance interruptions.

Solution: Employ rotary unions with stainless steel rotors and long composite bearings protected by O-rings to withstand poor water quality and abrasive media. Regular preventive maintenance and lubrication schedules extend service life and reduce unexpected failures.

3. Difficult Installation and Maintenance in Confined Spaces

Pain Point: Installation and replacement of rotary unions inside continuous casting machine rolls can be challenging due to limited space and complex assembly, causing prolonged downtime.

Solution: Opt for self-supported, journal-inserted rotary unions that mount directly into the roll journal, reducing space requirements and simplifying installation. Additionally, modular designs with easy-to-replace seals and components enable quicker maintenance and minimize production impact.

4. Vibration and Misalignment Issues Affecting Performance

Pain Point: Continuous casting machines experience vibration and mechanical stresses that can misalign rotary unions, causing uneven wear, seal failure, and operational noise.

Solution: Implement regular online vibration monitoring and mechanical calibration to maintain alignment within tight tolerances (e.g., deflections under 0.1mm). Proper alignment reduces wear and extends rotary union life, ensuring stable, quiet operation.

5. Operating Outside Specified Parameters Leading to Damage

Pain Point: Using rotary unions beyond their rated pressure, temperature, or speed can cause deformation, seal leakage, and mechanical overload, resulting in costly failures.

Solution: Select rotary unions rated for the specific continuous casting machine conditions, typically up to 150 PSI (10 bar) and 250°F (120°C), with maximum RPMs suited to slow roll speeds (~5 RPM). Always consult manufacturer specifications and seek expert advice to ensure correct product selection and avoid misuse.

Applications of Continuous Casting Machine Rotary Union

Coolant Transfer

Delivers water or oil-based coolants to molds and rollers, ensuring uniform solidification of steel slabs and reducing surface cracks.

Critical for maintaining the thermal gradient in curved continuous casters, where improper cooling can lead to subsurface defects.

Hydraulic Systems

Enables precise control of soft reduction mechanisms in continuous casting machines, minimizing centerline segregation in thick steel plates.

Supports secondary cooling systems by regulating spray water flow to optimize bloom surface quality.

Electromagnetic Stirring (EMS) Integration

Used in conjunction with EMS systems to enhance molten steel flow, improving grain structure and reducing internal voids.

Why Choose our Continuous Casting Machine Rotary Union?

Our Stainless Steel Continuous Casting Machine Rotary Union stands out due to its combination of quality materials, innovative design, and proven performance. With years of experience in the industry, we committed to providing solutions that enhance operational efficiency and reliability.