Deublin 902 121 188 Rotary Union Price

Original price was: $120.00.$108.00Current price is: $108.00.

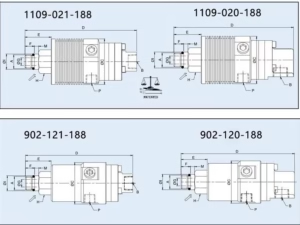

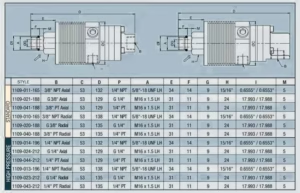

- Part Number: 902 121 188

- Max Coolant Pressure: 10 bar

- Max Speed: 20,000 RPM

- Max Flow Rate: 15 l/min

- Connection Type: Axial and Radial

- Material: Anodized Aluminum & SS

Description

Deublin 902-121-188 Rotary Union: Product Overview

Deublin 902-121-188 Rotary Union is a cutting-edge solution designed to meet the demanding needs of modern industrial applications. Engineered for seamless transfer of coolant and Minimum Quantity Lubrication, this rotary union ensures efficient operation in various machinery, enhancing productivity and reducing downtime.

Key Features of Deublin 902 121 188 rotary union

Single Passage Design

Specifically designed for use with coolant or MQL, this allows for efficient fluid transfer without obstruction.

Full-Flow Design

The rotary union boasts a full-flow design that prevents the trapping of swarf or debris, ensuring uninterrupted operation.

High-Quality Bearings

Equipped with deep-groove radial ball bearings, the 902-121-188 ensures smooth operation and longevity, even under heavy loads.

Robust Mechanical Seals

Constructed with balanced mechanical seals made from silicon carbide, this rotary union is built to withstand challenging operational conditions while minimizing wear and tear.

Corrosion-Resistant Housing

The anodized aluminum housing not only enhances durability but also protects against corrosion, extending the service life of the unit.

Product characteristics

Product characteristics

- Single channel coolant or MQL;

- Closed seal, automatic line, similar application;

- Deep groove ball bearings for smooth operatio.;

- Balanced mechanical seal made of silicon carbide;

- Bearing support with threaded rotor for easy installation;

- Full flow design, no debris and burr clogging Labyrinth system and large leakage port to protect ball bearings, ensuring long service life even in harsh operating environments;

- Anti-corrosion anodized aluminum housing.

Technical Specifications of Deublin 902 121 188 Rotary Union

| Item | Value |

|---|---|

| Speed | 12000-15000rpm |

| Temperature range | -30~+80℃ |

| Pressure | 70-100bar |

| Working medium | Hydraulic oil, water, coolant |

Technical Specifications

Technical Specifications

-

Maximum Pressure: 70 bar (1,015 psi) for reliable performance in high-pressure applications;

-

Maximum Flow Rate: 82 l/min (21.6 gpm) ensures efficient coolant delivery;

-

Maximum Operating Temperature: 71°C (160°F) suitable for demanding machining environments;

-

Maximum Speed: 12,000 RPM for high-speed machining operations;

-

Rotor Connection: M16x1.5 LH with 17.993 mm (0.708″) pilot for secure mounting;

-

Housing Connection: G 3/8″-19 standard fitting for easy integration;

-

Media Compatibility: Designed for water-based coolant or MQL (Oil Mist) applications.

Installation

To ensure maximum service life and reliability of the rotary joint, the installation engineer needs to follow these simple rules.

1. Before the rotary joint is installed on the spindle, the supply pipe and discharge hose of the joint should be connected first. Otherwise, when tightening the hose connection, the bearing of the joint will be subjected to a bending moment, and lock or wear.

2. The mounting surface of the spindle must be thoroughly cleaned before installing the rotary joint. The positioning holes of the spindle must be clean, free of chips, burrs, and dents. Otherwise, the joint will jump and vibrate when rotating.

3. Make sure that the discharge hose runs straight down the pipe without “waves”; otherwise, it will affect normal discharge. If it is a horizontal spindle, it must be ensured that the discharge hose of the joint is connected downward at the 6 o’clock position.

4. Before installation, the impurities in the roller (drying cylinder) should be cleaned with compressed air, and no impurities such as iron filings should be left.

5. When a threaded connection is used, the joint must be installed concentrically with the roller until it is tightened.

6. When the medium is steam or thermal oil, the connection needs to be coated with high-temperature sealant before installation.

7. The hanging holes on the rotary joint should be hung separately, and there should be room for buffering. It is not advisable to connect several joints in series.

8. After installation, start the machine without the medium for 10 minutes to make the rotary joint work better.

Maintenance

1. If there is an oil nozzle on the rotary joint, it should be refueled regularly (15 days).

2. When the seal can no longer play a sealing role, the seal should be replaced. Ordinary graphite products should be replaced once a year, and antimony-impregnated graphite, ceramic rings, and cemented carbide should be replaced once every three years.

Customer Pain Points & Solutions

1. Frequent Downtime Issues

Pain Point: Production losses due to rotary union failures during dry running conditions

Solution: Our technology allows unlimited dry running without media pressure, preventing seal damage when operating without coolant flow and eliminating unexpected downtime34

2. Clogging and Flow Restriction

Pain Point: Debris accumulation causing flow restrictions and tool damage

Solution: The full-flow design features no internal obstructions, preventing swarf and debris from accumulating and ensuring consistent coolant delivery to your tools.

3. Complex Installation Process

Pain Point: Difficult mounting procedures requiring specialized tools or expertise

Solution: Bearing-supported design with threaded rotor allows for straightforward installation and simplified maintenance procedures.

4. Premature Seal Failure

Pain Point: Frequent seal replacements in demanding machining operations

Solution: Silicon carbide balanced mechanical seals provide exceptional durability even under difficult operating conditions, significantly extending service intervals.

5. Corrosion and Environmental Damage

Pain Point: Rotary unions are degrading in wet machining environments

Solution: Anodized aluminum housing delivers superior corrosion resistance in demanding coolant applications34

6. Contamination of Spindle Bearings

Pain Point: Coolant leakage is damaging expensive spindle components

Solution: Engineered labyrinth system with large vents provides comprehensive protection for both the rotary union bearings and your machine spindle components.

7. Inconsistent Performance at High Speeds

Pain Point: Vibration and operational issues during high-speed machining

Solution: Premium deep groove radial ball bearings ensure smooth, reliable operation even at maximum speeds of 12,000 RPM

FAQ of Deublin 902 121 188 rotary union

FAQ of Deublin 902 121 188 rotary union

What is the Deublin 902-121-188 Rotary Union?

It is a rotary union design for single passage applications, specifically for coolant or Minimum Quantity Lubrication (MQL). It features Pop-Off™ technology, allowing for unlimited dry running without media pressure, making it ideal for various industrial applications.

What industries commonly use the Deublin 902-121-188?

Industries that benefit from this rotary union include: Machine Tool Manufacturing, Automotive Production, Aerospace Engineering, Robotics and Automation, and Food and Beverage Processing.

What are the maximum operational specifications of the Deublin 902-121-188?

The rotary union can handle: Max Coolant Pressure: 69 bar (1000 psi), Max Flow Rate for Coolant: 82 l/min (21.7 GPM), Max Flow Rate for MQL: 2040 l/min (72.1 CFM), Max Temperature: Up to 71 °C (160 °F) for both coolant and MQL applications.

How does the design prevent contamination?

The full-flow design of the 902-121-188 minimizes obstructions that could trap swarf or debris, which helps maintain fluid purity and prevents contamination in sensitive applications like machining and food processing.

What is the installation process like?

The rotary union features a threaded rotor connection for easy installation, ensuring a secure fit. Proper alignment with the spindle end is necessary to prevent vibration or wobble during operation, which can shorten service life.

Can the Deublin 902-121-188 be used in high-speed applications?

Yes, it is designed to operate at high speeds (up to 20,000 RPM), making it suitable for demanding environments such as CNC machining, where precision and efficiency are critical.