Pneumatic Rotary Coupling with Advanced Sealing and Low Torque

Original price was: $40.00.$30.00Current price is: $30.00.

- Maximum Air Pressure: Up to 250 PSI

- Maximum Rotational Speed: Up to 4,000 RPM

- Maximum Temperature: Up to 225°F (107°C)

- Seal Type: Silicon carbide to carbon graphite

- Material Options: Stainless Steel, Hastelloy

- Thread Types: NPT, BSP, Metric, and others

- Passage Options: Single or multiple air passages

Description

Product Overview

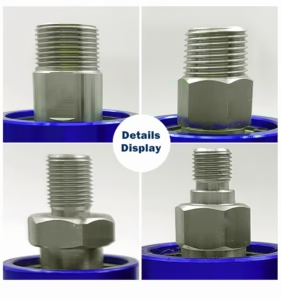

The Pneumatic Rotary Coupling is a precision-engineered solution designed to transfer compressed air, vacuum, water, oil, or coolant between stationary and rotating parts without twisting hoses or interrupting system flow. Built for continuous, leak-free rotation, this coupling ensures reliable performance in high-speed pneumatic circuits and industrial machinery.

Whether you need to supply air to robotic arms, pneumatic tools, or rotary tables, this air rotary coupling is the ideal component to enable smooth, unrestricted rotation while maintaining system integrity. With its low-torque design, durable construction, and advanced sealing technology, the pneumatic rotary coupling is trusted across industries for stable, high-speed operations.

This coupling is available in multiple sizes, connection types, and customizable configurations to meet the unique demands of automation systems, packaging equipment, CNC machinery, car wash systems, and other similar applications.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Type | Pneumatic Rotary Coupling |

| Body Material | Aluminum / Brass |

| Rotor Material | Stainless Steel / Carbon Steel |

| Seal Type | Balanced Mechanical Seal |

| Seal Combinations | Carbon-Graphite / Tool Steel or Silicon Carbide |

| Supported Media | Air, Vacuum, Hydraulic Oil, Water, Coolants |

| Maximum Speed | Up to 3000 RPM |

| Operating Pressure | Up to 150 PSI (customizable) |

| Connection Types | NPT, BSP, Flange, Custom |

| Temperature Range | -20°C to 120°C |

| Maintenance | Grease Fitting (3-5 Drops per Month Recommended) |

Key Features and Benefits

Reliable Pneumatic Air Transfer

This pneumatic rotary coupling ensures stable, continuous air or gas transmission between stationary supply lines and rotating machinery without leakage or interruption.

High-Speed Rotation

Engineered for precision, the coupling is designed to support high RPMs, making it ideal for fast-paced, high-output industrial environments.

Leak-Proof Sealing Technology

Equipped with advanced sealing mechanisms such as balanced mechanical seals and micro-lapped faces, this air rotary union effectively prevents air leakage, even under high pressure.

Durable Construction

Available in corrosion-resistant materials such as aluminum alloy, brass, and stainless steel, this pneumatic swivel joint is built for long-term reliability in harsh working conditions.

Compact and Lightweight Design

The compact structure allows for easy installation in space-limited systems while minimizing rotational inertia.

Multiple Passage Options

Single, dual, or multi-passage designs are available to independently transmit different media, including compressed air, vacuum, and low-pressure gases.

Versatile Shaft Connections

Compatible with a wide range of thread types (BSP, NPT, Metric) and flanged connections, ensuring seamless integration with existing setups.

Low Torque, Smooth Operation

Special bearing systems reduce friction and allow for smooth, low-torque rotation, minimizing wear and improving system efficiency.

Applications of Pneumatic Rotary Couplings

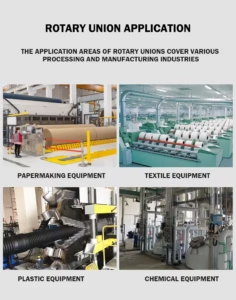

The Pneumatic Rotary Coupling is widely used across various industries:

🤖 Industrial Automation

Delivers continuous air and fluid transfer to rotating actuators, robotic arms, and conveyors.

🔩 Hydraulic Systems

Transfers hydraulic oil in rotating cylinders and presses, designed to handle high pressure and temperature.

💨 Pneumatic Equipment

Provides stable air flow for pneumatic tools, hose reels, and air-powered machinery.

🚗 Car Wash Systems

Facilitates water and detergent flow in rotating spray arms and brushes, ensuring efficient cleaning performance.

🏷️ Packaging and Printing

Supports rotary tables, spindles, and printing rollers requiring steady air or vacuum supply during high-speed operation.

🌬️ Renewable Energy

Used in wind turbine blade pitch control systems for reliable fluid and air transfer during continuous blade rotation.

Advantages of Pneumatic Rotary Coupling

1. Leak Prevention with Balanced Seals

Our pneumatic rotary unions feature balanced seals that automatically compensate for internal pressure fluctuations. This design minimizes face wear and ensures long-lasting, leak-free performance.

2. Precision Bearings for Smooth Rotation

High-quality precision ball bearings reduce rotational friction and enable stable, high-speed operation. This helps to extend equipment life and maintain consistent air delivery.

3. Corrosion-Resistant Materials

Constructed with robust materials such as anodized aluminum, nickel-plated brass, or stainless steel, these couplings resist corrosion from moisture-laden compressed air systems and challenging work environments.

4. Modular Design for Easy Maintenance

The modular structure allows quick disassembly for inspection, seal replacement, and cleaning, significantly reducing downtime and maintenance costs.

5. Multi-Passage Options for Complex Air Circuits

Dual and multi-passage versions allow the simultaneous transmission of compressed air, gases, or vacuum lines through independent channels without cross-contamination.

Why Choose Our Pneumatic Rotary Coupling?

Over 10 Years of Industry Experience

Proven expertise in pneumatic rotary joint design and manufacturing, trusted by global industries.

Factory Direct Pricing

We offer competitive, factory-direct pricing with no intermediaries.

Fast Customization and Delivery

Quick response for customized sizes, seal materials, and connection types to fit your system needs.

Dedicated Technical Support

Our experienced engineers provide one-on-one technical consultation to help you select the right rotary coupling.

Strict Quality Control

Each pneumatic rotary coupling undergoes rigorous pressure, leak, and rotation testing before shipment.

FAQ

FAQ

Q1: Can the Pneumatic Rotary Coupling handle vacuum systems?

A1: Yes, it is specifically designed to handle both vacuum and positive pressure applications.

Q2: Is this coupling suitable for high-speed applications?

A2: Absolutely. The coupling supports speeds up to 3000 RPM, depending on the selected model.

Q3: How often should I lubricate the coupling?

A3: We recommend adding 3-5 drops of grease per month via the provided grease fitting.

Q4: Can I customize the shaft connection?

A4: Yes, we offer NPT, BSP, flange, and custom thread options to fit your system.

Q5: Is the coupling maintenance-free?

A5: The ball bearings are permanently lubricated for minimal maintenance, but light monthly lubrication is recommended for optimal performance.

Instructions for Use

🔹 Keep Equipment Clean

🧹 Regularly clean the drum and pipe walls.

🆕 Pay special attention to new equipment.

🔍 Add filters if needed to prevent foreign matter from causing wear.

🔹 Handle Leaks Promptly

⚠️ If leakage occurs, stop the machine immediately.

🚫 Do not continue high-speed operation to prevent serious damage.

🔹 Avoid Long-Term Idle Running

⏸️ Do not run the rotary joint without media for long periods.

🔧 Prolonged idle use may cause internal damage.

🔹 Prevent Rust After Downtime

🕰️ Long-term inactivity may lead to internal rust.

🧼 Always clean the rust before restarting to avoid jamming or dripping.

🔹 Regular Lubrication

🛢️ For oiling devices, lubricate regularly.

✅ Ensures smooth bearing performance and extends service life.

🔹 Gradual Heating for Hot Media

🔥 Gradually increase temperature when using hot media.

🚫 Avoid sudden temperature changes to prevent system stress.

Conclusion

Our Pneumatic Rotary Coupling is the ideal choice for industries seeking reliable, high-speed rotary unions that maintain airtight pneumatic connections under demanding conditions. With superior sealing, robust materials, and versatile configurations, it ensures your pneumatic systems operate smoothly and efficiently. Invest in our rotary coupling for enhanced productivity, reduced maintenance, and long-term operational excellence.