Rotary Union for Steam – Q Series for Heat Transfer Equipment

Original price was: $15.00.$13.00Current price is: $13.00.

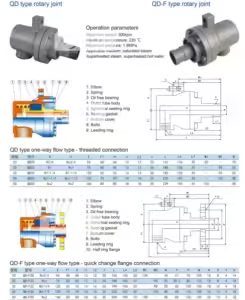

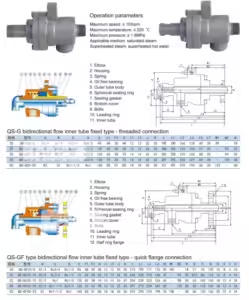

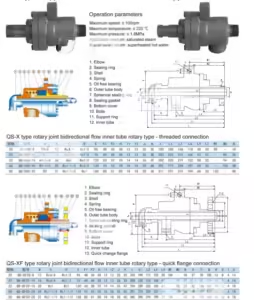

- Model: Q Series

- Medium: Steam, Hot Oil

- Passages: Single Flow

- Pressure Rating: Up to 150 PSI

- Temperature: Up to 200°C / 392°F

- Speeds: Up to 1,000 RPM

- Connection Types: NPT, BSPT, Custom Threading Available

- Material: Ductile Iron Housing, Hardened Steel Rotor, Graphite Seals

Description

The Q Series Rotary Union for Steam, also known as a steam swivel union or rotary connector, is engineered to provide a leak-proof and maintenance-free solution for transferring steam or hot water between stationary and rotating machinery. It ensures consistent, efficient heat exchange—driving up productivity and minimizing energy loss across your plant floor. It is specifically engineered to handle high-temperature steam transfer in demanding industrial applications. Designed for longevity and minimal maintenance, this single-passage rotary union is ideal for steam cylinders, drying rolls, rotary drums, and rotating vessels across various industries such as textile, paper, rubber, plastic, and food processing.

Its rugged construction ensures reliable sealing even under continuous thermal cycling and high-pressure steam conditions. Built with premium stainless steel or carbon steel, the Q Series Rotary Union is designed for the harshest industrial environments. It can withstand temperatures up to 235°C (455°F) and pressures as high as 11 bar (160 psi), reliably maintaining performance under demanding operating cycles. The convex-surface seal technology and imported graphite rings provide superior sealing, while the multi-spring assembly compensates for any axial misalignment, extending operational longevity. With field-proven performance and compatibility with global threading standards, the Q Series delivers the flexibility and performance industrial operations demand.

Key Features

Steam-Optimized Seal Design

The Q Series rotary union features a specially formulated carbon graphite seal that can withstand thermal shock, ensuring long-lasting operation in high-pressure steam systems. The balanced mechanical seal maintains tight contact even during thermal expansion.

Durable Housing and Rotor

Constructed with a ductile iron housing and precision-ground steel rotor, the Q Series offers exceptional strength and wear resistance, making it suitable for continuous operation in steam environments.

Single-Passage Configuration

Its single-flow design is ideal for direct steam transfer applications, allowing efficient heat exchange and consistent performance. It also reduces internal complexity, making maintenance and inspection easier.

High-Temperature and Pressure Tolerance

Rated up to 200°C (392°F) and 150 PSI, the Q Series handles saturated and superheated steam with ease. This makes it a perfect solution for high-speed rotary steam systems.

Versatile Connection Options

Available in NPT, BSPT, and custom thread options, it integrates seamlessly into both American and international piping systems. The flanged design is also available for OEM applications.

Why Choose Q Series?

Energy Efficiency

Maximum thermal transfer with minimal steam loss due to advanced sealing systems.

Safety First

Built-in pressure release options and customizable expansion features protect against overpressure and thermal shock.

Universal Fit

Multiple connection sizes (3/8″, 1/2″, 1 1/4″, etc.) and adaptable design for domestic and international equipment standards.

Maintenance-Free Operation

Extended service intervals thanks to optimized seal and spring assemblies—no regular lubrication or adjustment needed.

Applications of Q Series Rotary Union for Steam

The Q Series Rotary Union is the go-to solution for rotating equipment where steam, thermal oil, or hot water must be reliably transferred into or out of a rotating part. Below are key industries and applications:

Textile Industry

- Drying Cylinders: Transfers steam into rotating drums for fabric drying in printing and dyeing processes.

- Calendar Rolls: Ensures uniform heating in compression and finishing operations.

- Stenter Machines: Delivers precise temperature control for heat-setting fabrics.

Benefit: Maintains uniform heat distribution, improving fabric quality and production efficiency.

Paper & Pulp Industry

- Steam-Heated Rolls: Used in paper drying sections for consistent moisture removal.

- Coating Machines: Delivers steam to rolls that apply coatings evenly across paper surfaces.

Benefit: Enhances drying performance, reduces energy costs, and increases production speed.

Rubber & Plastic Processing

- Roller Heating Systems: Maintains steady mold and roller temperature during extrusion, calendering, and forming.

- Vulcanization Drums: Transfers steam to rotary vulcanization systems for tire and rubber part manufacturing.

Benefit: Improves process control and material consistency under varying load conditions.

Food & Beverage Industry

- Rotary Steam Kettles: For cooking, sterilization, and pasteurization of sauces, soups, and dairy products.

- Jacketed Mixing Vessels: Provides uniform heating for mixing operations in confectionery and dairy.

Benefit: Offers hygienic, leak-proof operation with no lubricant contamination risk.

Chemical & Pharmaceutical Industry

- Rotating Reactors: Transfers thermal energy to rotating vessels used in chemical synthesis or pharmaceutical production.

- Distillation Equipment: Steam injection into rotating parts of distillation or evaporation equipment.

Benefit: Resistant to aggressive chemicals, high temperatures, and pressure fluctuations.

Printing & Lamination

- Heated Rollers: Maintains precise roller temperature for lamination and thermal transfer printing.

- Hot Foil Stamping Machines: Provide heat to rotary components for foil bonding.

Benefit: Improves product finish, reduces cycle time, and increases process consistency.

Why Choose Our Q Series Rotary Union?

Selecting the right rotary union for steam systems is crucial to ensure reliability, energy efficiency, and long-term performance. Here’s why our Q Series Rotary Union for Steam stands out among competitors:

Engineered for High-Temperature Steam Applications

Unlike general-purpose rotary unions, the Q Series is specifically built for saturated and superheated steam. Its graphite-based mechanical seal ensures a tight, leak-proof connection even under thermal cycling and rapid pressure changes.

Drop-In Replacement for Leading Brands (e.g., Deublin, Kadant)

Our Q Series can directly replace Deublin 1115, 1121, and similar models. You get the same or better performance—at 30–50% lower cost—with no system modifications required. This helps reduce downtime and simplifies procurement for OEMs and MRO operations.

Robust Materials for Demanding Industrial Use

We use ductile iron housings, hardened alloy steel rotors, and graphite-carbon composite seals to ensure long service life. These materials are resistant to erosion, scale buildup, and corrosion caused by high-pressure steam and condensate.

Custom Configurations Available

Need BSPT instead of NPT? Flanged inlet instead of threaded? Port size change? No problem. Our engineers offer tailored solutions to meet your application’s exact requirements, with low minimum order quantities and fast lead times.

Competitive Pricing & Global Shipping

We are a leading rotary union manufacturer in China, specializing in affordable, high-performance alternatives to expensive Western brands. With large inventory and express logistics, we support OEM customers, wholesalers, and end users around the world.

FAQ

Q: Can this rotary union handle superheated steam?

A: Yes, the Q Series is designed to tolerate superheated steam up to 200°C and 150 PSI, making it suitable for high-temperature processes.

Q: Is this rotary union compatible with hot oil applications?

A: While primarily designed for steam and hot water, Q Series Unions may be customized for hot oil. Please contact us to discuss your requirements in detail.

Q: What industries can benefit from this rotary union?

A: Industries such as printing, textile, paper, chemical, food processing, and energy — any application requiring reliable rotary steam/hot water transfer.

Q: What is the maintenance schedule?

A: The optimized seal and robust build ensure maintenance-free performance, reducing downtime and labor costs.

Q: Can the Q Series be customized for special operating conditions?

A: Yes, we offer customizable designs to meet non-standard temperature, pressure, or mounting configurations.

Global Shipping & Support

We ship Q Series rotary joints worldwide with expedited options available. All units are tested before dispatch and backed by a 12-month warranty. Our technical team can assist with installation, troubleshooting, or custom design needs.

Customer Reviews

“Great value for steam drying lines. We’ve replaced Deublin models with these and saved 40% without sacrificing performance.”

— Zhao W., Textile Plant Engineer, Vietnam

“Solid rotary union for our food kettle systems. Easy to install, runs cool and tight.”

— Carlos M., Process Engineer, Mexico

“Needed custom BSPT threading and they delivered in 5 days. Will buy again for sure.”

— James K., OEM Machinery Integrator, UK

Order Now or Request a Quote

We specialize in cost-effective, high-quality alternatives to global rotary union brands like Deublin and Kadant. Whether you’re sourcing OEM machinery or aftermarket replacement, our Q Series Rotary Union for Steam delivers on price, performance, and support.

👉 Contact us now to request a quote or discuss custom requirements.