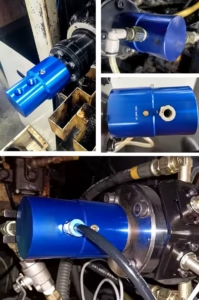

Rotary Union For Multiple Media

Original price was: $300.00.$255.00Current price is: $255.00.

- Max Pressure: Up to 10,000 PSI (690 bar)

- Max Temperature: Up to 200°C (392°F)

- Number of Passages: Up to 12 independent passages

- Rotational Speed: Up to 3,000 RPM

- Materials: Stainless Steel, Carbon Graphite Seals

- Seal Type: Balanced Mechanical Seals

Description

Our Rotary Unions for Multiple Media are designed for applications requiring the simultaneous transfer of different media—such as air, water, hydraulic oil, coolant, and vacuum—through a single rotating interface. Engineered for reliability and efficiency, these multi-passage rotary unions ensure continuous, leak-free media transfer between stationary and rotating components in demanding industrial environments.

The housing is precision-machined from high-strength aluminum alloy or stainless steel, while advanced sealing technologies prevent cross-contamination between media passages. Whether you operate in automation, packaging, robotics, or CNC machining, these rotary unions ensure seamless performance and a long service life.

Superior Sealing and Longevity

The Deublin 2620 Series features a unique balanced sealing system that provides unparalleled protection against wear and leaks, ensuring long-lasting, reliable performance. The carbonized silicon sealing components are highly effective in sealing various media types, including:

-

Purified filtered water

-

Coolants

-

Oil-water mixtures

-

Compressed air

The sealing rings are designed with precise, tight tolerances, ensuring that pressure across the seal surface remains balanced and stable, even under extreme operating conditions. This precise balance significantly reduces torque and enhances the rotary union’s lifespan, making it an optimal choice for continuous operation.

Labyrinth Seal Structure for Enhanced Protection

The labyrinth seal provides an additional layer of protection to the ball bearings, preventing contaminants and moisture from damaging the internal components. This robust design ensures that the rotary union continues to function smoothly even in harsh working conditions.

Reliability at High Pressures

Even at maximum operating pressures, the Deublin 2620 Series maintains a reliable seal and continuous fluid flow. The balanced mechanical seals on each channel further optimize the rotary union’s resistance to wear and tear, ensuring high-performance operation for extended periods without compromising the integrity of the seals.

Precision Engineering for Optimal Performance

Every aspect of the manufacturing process is carefully controlled to maintain the highest standards of quality. From component fabrication to final assembly, each rotary union is meticulously crafted to meet or exceed the technical specifications required for top-tier industrial applications. With the use of advanced manufacturing techniques and high-quality materials, the Deublin 2620 rotary union ensures:

-

Minimum friction

-

Reduced torque

-

Enhanced efficiency

-

Extended operational life

Key Features

1. Aluminum Alloy Housing: Durable and Corrosion-Resistant

-

High-Strength Aluminum Alloy: Constructed with premium aluminum alloy, the rotary union is both lightweight and durable, providing superior strength without adding unnecessary weight.

-

Anodized Surface Treatment: The surface is treated with an anodized finish, which significantly enhances corrosion resistance, making it ideal for harsh environments. The anodized coating also provides increased wear resistance, ensuring long-lasting performance and minimal maintenance.

-

Perfect for Harsh Environments: Whether exposed to moisture, chemicals, or high temperatures, this robust housing guarantees the rotary union will perform reliably, even under extreme conditions.

2. Dual-Channel Flow Mechanism: Simultaneous Media Transfer

-

Independent Dual Channels: Designed for simultaneous fluid transfer, this rotary union features a dual-channel system that can carry two separate media streams at once. Perfect for applications such as clamping, release, and cooling.

-

Efficient Fluid Transfer: Each channel operates independently, allowing for separate media flows without cross-contamination, making it suitable for systems that require different fluids under different conditions.

-

Enhanced Application Versatility: Ideal for use in automated machinery and industrial systems, this design supports precise and simultaneous fluid transfer and thereby optimizes overall operational efficiency.

3. Self-Supporting Rotary Connector: Easy Integration and Precise Control

-

Self-Supporting Design: This feature eliminates the need for external supports, making the rotary union easier to integrate into various systems, reducing complexity and saving space.

-

Precise Clamping and Releasing: The independent clamping and releasing functionality of each channel makes the rotary union suitable for workpiece sensing and cooling applications, where precise fluid control is required alongside mechanical actions.

-

Ideal for Automated Systems: Perfect for integration into robotic arms, production lines, or systems where fluid transfer must coincide with machinery movements.

4. Flange Mounting: Secure and Flexible Installation

-

Easy and Secure Installation: The rotary union features a flange-based mounting connection. It allows easy installation while securely attaching to a wide range of machine components.

-

Flexible Orientation: Flange mounting allows for multiple installation orientations (horizontal, vertical, angled), offering versatility in machine integration.

-

Durable Connection: This connection method ensures a strong and stable attachment, even in dynamic environments with vibrations or movement.

5. Dual Precision Ball Bearings: Smooth and Reliable Operation

-

Precision Bearings: The rotary union features dual precision ball bearings, ensuring smooth and friction-free rotation for continuous, high-performance operation.

-

Longer Service Life: These high-quality bearings withstand high loads. It delivers long-lasting, reliable operation, significantly reducing the need for frequent maintenance.

-

Labyrinth Seal Protection: The labyrinth seal actively protects the bearings and thereby prevents contaminants and moisture from causing damage, ensuring reliable performance even in harsh operating environments.

Technical Specifications

| Parameter | Description |

|---|---|

| Media Types | Air, Water, Hydraulic Oil, Coolant, Vacuum |

| Passages Available | 2 / 4 / 6 / 8 / 10 passages |

| Maximum Pressure | Up to 30 MPa |

| Maximum Speed | Up to 3000 RPM |

| Temperature Range | -40°C to +180°C |

| Housing Material | Aluminum Alloy / Stainless Steel (304, 316 optional) |

| Seal Materials | Carbon Graphite, Ceramic, Nitrile, Viton, or PTFE |

| Bearing Type | Sealed Deep Groove Ball Bearings |

| Mounting Options | Threaded, Flanged, or Custom Mounts |

| Media Isolation | 100% cross-contamination prevention |

| Customization | Available upon request |

Applications

-

Automated Machinery: Clamping, release, and cooling applications in industrial robots or automated systems.

-

Oil & Gas Industry: For high-pressure and multi-media fluid transfer.

-

Manufacturing & CNC Machines: For workpiece sensing, cooling systems, and hydraulic operations.

Why Choose Us

Our Rotary Unions for Multiple Media deliver precision engineering and therefore meet the rigorous demands of modern industrial applications with confidence and consistency. With a commitment to quality and performance, these rotary unions not only comply with industry standards but also enhance operational capabilities across various sectors.

-

OEM Replacement Capability: Compatible with major brands like Deublin, Maier, Kadant, and Ott-Jakob.

-

Global Export Experience: Trusted by customers across Europe, North America, and Asia.

-

Custom Engineering Support: We offer design consultation for non-standard configurations or extreme operating conditions.

-

Competitive Pricing: High-quality manufacturing with a price advantage compared to global competitors.

Conclusion

The Deublin 2620 Series Dual Channel Multi-Media Rotary Union is the perfect solution for industries requiring reliable, efficient, and long-lasting fluid transfer in complex and high-demand systems.