Rotary Coupling Seal Kits- A Comprehensive Guide

In the dynamic realm of industrial machinery, where precision and reliability are the cornerstones of efficient operations, rotary coupling seal kits stand as unsung heroes. I’ve witnessed a growing trend in searches related to “rotary seal coupling supplier,” indicating the suppliers of rising demand for in-depth knowledge on this crucial component.

In this blog, we’ll embark on an extensive exploration of rotary coupling seal kits, delving into their significance, components, installation, maintenance, and diverse applications.

What are Rotary Coupling Seal Kits?

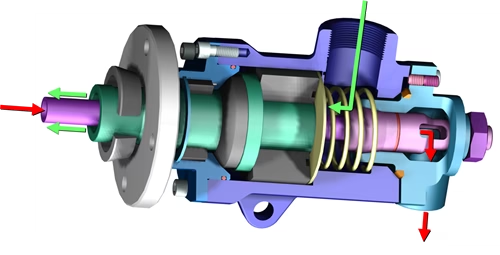

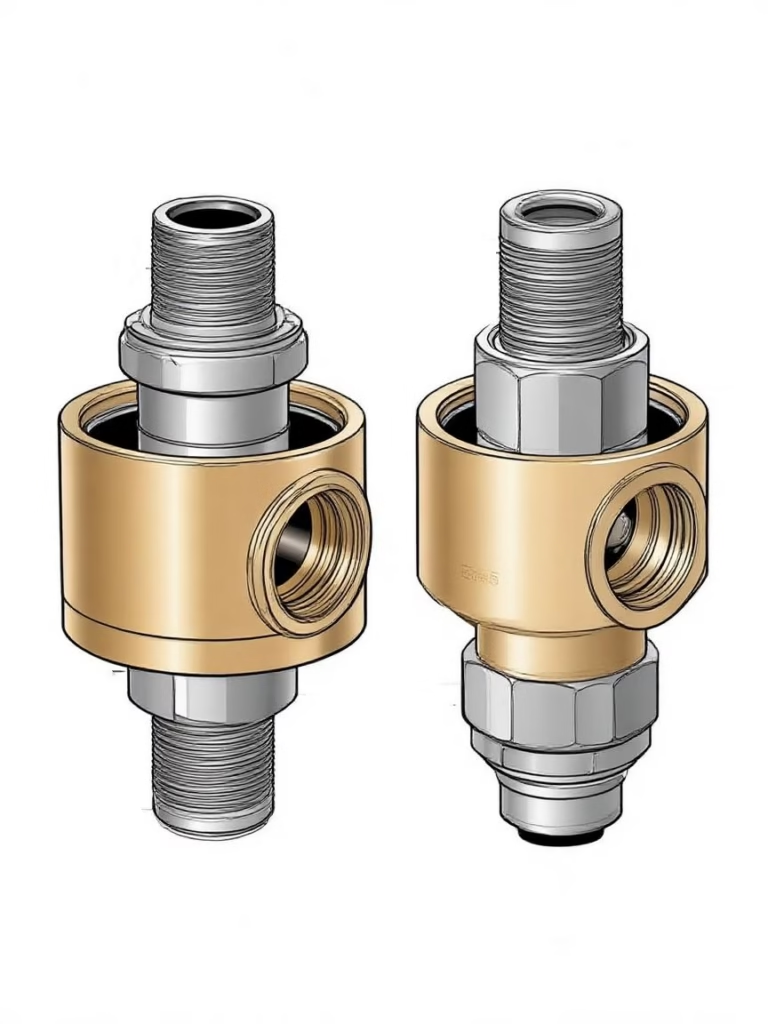

Before diving into the details, it’s essential to define what rotary coupling seal kits are. A rotary coupling is a mechanical device that connects two shafts to transmit power while allowing for some degree of misalignment. Seal kits for rotary couplings include components that actively create a barrier to prevent fluids, gases, or contaminants from leaking into or out of the coupling area. These kits play a vital role in maintaining the integrity of the coupling system, ensuring smooth operation, and extending the lifespan of the machinery.

Rotary coupling seal kits come in various configurations, tailored to different types of rotary couplings and operating conditions. Whether it’s in high-speed manufacturing processes, heavy-duty industrial applications, or precision-oriented equipment, the right seal kit can make a significant difference in performance and durability.

The Significance of Rotary Coupling Seal Kits

Preventing Leakage

One of the primary functions of rotary coupling seal kits is to prevent leakage. In industrial settings, fluids such as lubricants, hydraulic oils, or process chemicals often circulate within the machinery. Leakage not only leads to the wastage of valuable resources but can also cause environmental pollution and pose safety hazards. For example, in a hydraulic system, a leak in the rotary coupling can result in a pressure drop, affecting the performance of the entire system. A well-designed seal kit creates a tight seal, ensuring that fluids remain within the designated pathways.

Protecting Against Contamination

In addition to preventing fluid leakage, seal kits safeguard the coupling from external contaminants. Dust, dirt, moisture, and other particles can easily find their way into the coupling area if not properly sealed. These contaminants can cause abrasion, corrosion, and premature wear of the coupling components. In a food processing plant, for instance, any ingress of contaminants into the rotary coupling of mixing equipment can contaminate the food product, leading to quality issues and potential recalls. Seal kits act as a protective shield, keeping the coupling clean and free from harmful particles.

Enhancing Machinery Performance

By maintaining a proper seal and preventing contamination, rotary coupling seal kits contribute significantly to enhancing the overall performance of the machinery. A leak-free and clean coupling allows for efficient power transmission, reducing energy losses and improving operational efficiency. When the coupling operates smoothly, it also minimizes vibrations and noise, creating a more comfortable and productive working environment. This is especially crucial in applications where precision is key, such as in CNC machining or medical equipment.

Extending Equipment Lifespan

Regularly replacing and maintaining seal kits can greatly extend the lifespan of the rotary coupling and the connected machinery. Without proper sealing, harsh operating conditions directly impact the coupling components and accelerate their wear and tear. By investing in high-quality seal kits and following a maintenance schedule, you can prevent costly breakdowns and replacements, saving both time and money in the long run.

Rotary Seal Coupling Supplier

Sealing Elements

The heart of any seal kit is the sealing elements. These typically include O-rings, lip seals, and mechanical seals.

O-rings:

O-rings are one of the most commonly used sealing elements in rotary coupling seal kits. They are simple, cost-effective, and versatile. Made from materials such as rubber, silicone, or fluorocarbon, O-rings create a tight seal by deforming slightly when compressed between two mating surfaces. They are suitable for a wide range of applications, from low-pressure to moderate-pressure systems, and can withstand different temperatures depending on the material used.

Lip Seals:

Lip seals, also known as radial shaft seals, consist of a rubber or elastomeric body with a flexible lip. The lip presses against the rotating shaft, creating a seal that prevents the leakage of fluids and the ingress of contaminants. Lip seals are often used in applications where there is a need to seal against a rotating shaft, such as in pumps, motors, and gearboxes. They are effective in handling both static and dynamic sealing conditions.

Mechanical Seals:

Mechanical seals are more complex and sophisticated compared to O-rings and lip seals. They typically consist of two mating surfaces, one stationary and one rotating, along with a spring-loaded assembly. The mating surfaces create a tight seal, and the spring ensures that the surfaces remain in contact even under varying operating conditions. Mechanical seals are commonly used in high-pressure, high-temperature, and high-speed applications, where a more reliable and durable seal is required.

Gaskets:

Gaskets are flat, thin pieces of material that are placed between two mating surfaces to create a seal. In rotary coupling seal kits, gaskets are used to seal the joints between the coupling halves, flanges, or other components. They are made from materials such as rubber, cork, paper, or metal, depending on the application requirements. Gaskets help to prevent leakage of fluids and gases and also provide a cushioning effect, reducing vibrations and noise.

Backup Rings:

Backup rings are often used in conjunction with O-rings, especially in high-pressure applications. They are made from harder materials, such as plastic or metal, and are placed on the side of the O-ring opposite to the pressure source. The backup ring prevents the O-ring from extruding into the clearance gap between the mating surfaces under high pressure, which can cause the O-ring to fail. By using backup rings, you can increase the pressure-handling capacity of the seal and extend its lifespan.

Installation Tools

Many seal kits also come with installation tools. These tools are specifically designed to help install the sealing elements correctly, without causing damage. For example, O-ring installation tools can help stretch and position the O-ring without tearing it. Proper installation tools ensure that the seal kit components are installed accurately, which is crucial for achieving a reliable seal.

Installation of Rotary Seal Coupling Kits

Preparation

Before installing a rotary coupling seal kit, thorough preparation is essential. First, clean the coupling surfaces thoroughly to remove any dirt, debris, or old sealant residue. Use appropriate cleaning solvents and tools, such as brushes or rags, to ensure a clean surface. Inspect the coupling components for any signs of damage, such as cracks, scratches, or wear. If any damage is detected, repair or replace the damaged parts before proceeding with the installation.

Selecting the Right Rotary Seal Coupling

Ensure that you have the correct seal kit for your specific rotary coupling model and operating conditions. Check the manufacturer’s specifications and guidelines to confirm that the seal kit components are compatible with the coupling and the fluids or gases it will handle. Using the wrong seal kit can lead to poor sealing performance and potential failure.

Installing the Sealing Elements

Follow the manufacturer’s instructions carefully when installing the sealing elements. For O-rings, lubricate them slightly with a compatible lubricant to ease installation and prevent damage. Place the O-ring in the designated groove, ensuring that it is seated properly and there are no twists or kinks. When installing lip seals, make sure the lip is facing the correct direction (usually towards the fluid source) and that it makes proper contact with the rotating shaft. For mechanical seals, assemble the components according to the provided instructions, ensuring that the mating surfaces are clean and free from any contaminants.

Tightening and Alignment

After installing the sealing elements, assemble the coupling halves and tighten the bolts or fasteners to the recommended torque specification. Use a torque wrench to ensure consistent and accurate tightening. Also, check the alignment of the shafts connected by the coupling. Proper alignment is crucial for the smooth operation of the coupling and the longevity of the seal kit. Misalignment can cause excessive stress on the seal, leading to premature failure.

Maintenance of Rotary Coupling Seal Kits

Regular Inspection

Regularly inspect the rotary coupling and the seal kit for any signs of leakage, wear, or damage. Look for fluid stains, drips, or visible signs of contamination around the coupling area. Check the sealing elements for cracks, tears, or signs of hardening. Inspect the bolts and fasteners to ensure they are tight and not loose. Early detection of issues can prevent more significant problems from occurring.

Lubrication

If the seal kit components require lubrication, follow the manufacturer’s recommendations for lubricant type, frequency, and application method. Proper lubrication helps to reduce friction, prevent wear, and ensure the smooth operation of the sealing elements. However, be careful not to over-lubricate, as excess lubricant can attract dirt and contaminants.

Replacement

Over time, the sealing elements in the seal kit will wear out and lose their effectiveness. Follow the manufacturer’s recommended replacement intervals for the seal kit components. Even if there are no visible signs of damage, it’s a good practice to replace the seal kit at regular intervals to maintain optimal performance. When replacing the seal kit, follow the installation procedures carefully to ensure a proper seal.

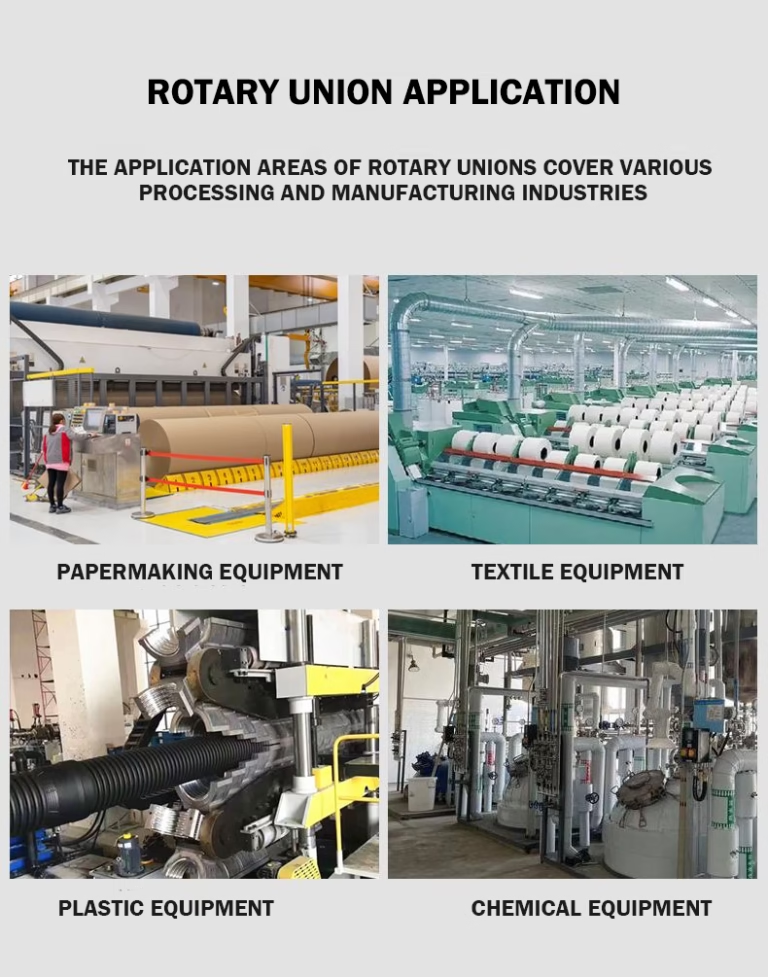

Applications of the rotary seal coupling

Manufacturing Industry

In the manufacturing industry, rotary coupling seal kits are used in a wide variety of machinery, including conveyor systems, machine tools, and assembly lines. In conveyor systems, seal kits prevent the leakage of lubricants from the couplings that drive the conveyor belts, ensuring smooth and continuous operation. And in machine tools, such as lathes, mills, and drills, seal kits protect the couplings from coolant, chips, and other contaminants, maintaining the precision and accuracy of the machining operations.

Automotive Industry

The automotive industry relies on rotary coupling seal kits in engines, transmissions, and other powertrain components. In engines, seal kits prevent the leakage of engine oil, coolant, and combustion gases, ensuring efficient engine performance and reducing emissions. In transmissions, they keep the transmission fluid sealed, enabling smooth gear shifting and preventing damage to the transmission components.

Aerospace Industry

In the aerospace industry, where reliability and safety are of utmost importance, rotary coupling seal kits play a critical role. They are used in aircraft engines, landing gear systems, and hydraulic systems. Seal kits in aircraft engines prevent the leakage of high-temperature gases and lubricants, ensuring the engine’s performance and safety during flight. In hydraulic systems, they maintain the integrity of the hydraulic fluid, enabling the proper operation of landing gear and other critical components.

Energy Sector

In the energy sector, rotary coupling seal kits are used in power generation equipment, such as turbines, generators, and pumps. In steam turbines, seal kits prevent the leakage of steam, which can reduce the efficiency of power generation. Pumps used for oil and gas extraction prevent the leakage of oil, gas, or other fluids, ensuring safe and efficient operation.

Choosing the Right Rotary Coupling Seal Kit

Consider the Operating Conditions

When choosing a rotary coupling seal kit, the first factor to consider is the operating conditions. Take into account the temperature, pressure, speed, and type of fluid or gas that the coupling will handle. For example, if the application involves high temperatures, choose a seal kit made from materials that can withstand high-temperature environments, such as fluorocarbon or silicone. If the pressure is high, select a seal kit with components that have a high-pressure-handling capacity.

Compatibility with the Coupling

Ensure that the seal kit is compatible with the specific rotary coupling model you are using. Different couplings may have different sealing requirements and configurations. Check the manufacturer’s specifications and consult with experts if necessary to ensure a proper fit. Using an incompatible seal kit can lead to sealing failures and potential damage to the coupling and the connected machinery.

Quality and Brand Reputation

Invest in high-quality seal kits from reputable manufacturers. A well-known brand is more likely to provide reliable products that meet industry standards. Read customer reviews and testimonials to get an idea of the product’s performance and durability. While high-quality seal kits may be more expensive upfront, they can save you money in the long run by reducing the frequency of replacements and preventing costly breakdowns.

Cost-Benefit Analysis

Finally, conduct a cost-benefit analysis. Consider not only the initial cost of the seal kit but also the long-term costs associated with maintenance, replacement, and potential downtime due to seal failures. A cheaper seal kit may seem like a good deal initially, but if it requires frequent replacements or causes machinery breakdowns, it can end up costing more in the long term. Choose a seal kit that offers the best balance between cost and performance.

FAQs About Rotary Seal Coupling Supplier

Q1: What factors should I prioritize when selecting a rotary coupling seal kit for high-pressure hydraulic systems?

A: For high-pressure applications (e.g., hydraulic systems exceeding 3,000 PSI), prioritize seals with PTFE-backed primary seals to resist extrusion under pressure. Check the kit’s pressure rating (typically marked in PSI or bar) and ensure it matches your system’s maximum operating pressure. Also, verify compatibility with your hydraulic fluid—nitrile seals work for mineral oils, but fluorocarbon (Viton®) is required for phosphate esters or synthetic fluids. Finally, choose kits with metal backup rings to prevent seal deformation during pressure spikes.

Q2: Can I reuse components from an old seal kit during installation?

A: No, reusing old components is a common mistake that compromises performance. Even if a backup ring or wiper appears intact, micro-cracks or deformations from previous use can lead to premature failure. Always replace every component in the kit, including O-rings, seals, and washers. Pro tip: Label and discard old parts immediately to avoid accidental reuse.

Q3: How often should I inspect rotary coupling seals in heavy-duty equipment like excavators or cranes?

A: In high-wear environments (e.g., construction sites with dust, vibration, or extreme temperatures), inspect seals weekly for signs of leakage, discoloration, or hardening. Use a thermal camera to detect uneven heat distribution, which often indicates misalignment or seal friction. For low-risk applications (e.g., indoor machinery), monthly checks suffice. Regardless of environment, replace seals at 70–80% of their rated lifespan—waiting for failure risks collateral damage to couplings and bearings.

Conclusion

Rotary coupling seal kits are indispensable components in industrial machinery, playing a crucial role in preventing leakage, protecting against contamination, enhancing performance, and extending equipment lifespan. Understanding their components, installation, maintenance, and applications is essential for ensuring the smooth operation of machinery and optimizing content related to them for better search rankings. If you have any further questions or need more in-depth information on specific aspects of rotary coupling seal kits, feel free to leave a comment below.