Rotary Union manufacturer choose

Decoding the Decision-Making of Rotary Union Manufacturer

Rotary unions, often overlooked yet indispensable, serve as the linchpin in industrial machinery, enabling the seamless transfer of fluids and gases between stationary and rotating components. For manufacturers in this specialized field, the decisions made in product development, supplier selection, and market strategy are not just operational choices—they are the keys to unlocking success in a highly competitive and dynamic industry. This blog post will dissect the intricate web of factors influencing these decisions, explore the decision-making process in depth, and offer insights into the future outlook for rotary union manufacturer.

Understanding the Rotary Union Market Landscape

Market Dynamics and Growth Trends

The global rotary union market has been on an upward growth curve in recent years, with a compound annual growth rate (CAGR) hovering around 4 – 5%.

The surge in automation across manufacturing industries is a significant catalyst. As factories strive for increased efficiency and productivity, the demand for reliable rotary unions that can withstand the rigors of high-speed, continuous operation has soared. For example, in automotive manufacturing plants, where robotic arms equipped with rotary unions perform tasks such as painting, welding, and assembly, any disruption in the performance of these components can lead to costly production delays.

The expansion of the renewable energy sector is another major contributor. Wind turbines, which rely on rotary unions to transfer hydraulic fluids for pitch control and lubricants for gearbox operation, are being installed at an unprecedented rate. According to the Global Wind Energy Council, the cumulative installed wind power capacity globally reached over 837 GW in 2022, and this number will continue growing. Each new wind turbine installation represents a potential opportunity for rotary union manufacturers.

Moreover, the increasing emphasis on energy-efficient industrial equipment has led to a demand for rotary unions that can minimize energy losses during fluid transfer. Manufacturers are constantly researching and developing new designs and materials to meet these requirements.

Key Players and Their Market Share

The rotary union industry is a diverse ecosystem, consisting of both large multinational corporations and smaller specialized manufacturers. Among the industry giants, DEUBLIN, a leading provider of rotary unions and related products, has established a strong foothold in the market. With a history spanning over 80 years, DEUBLIN has built a reputation for delivering high-quality, reliable products, particularly in the high-end and specialized rotary union segments. Their products apply to industries such as aerospace, medical, and semiconductor manufacturing, where precision and reliability are of utmost importance.

However, the industry is not dominated solely by these large players. Smaller manufacturers often find their niche by focusing on specific industries or offering specialized services. For example, some manufacturers specialize in producing rotary unions for the food and beverage industry, ensuring that their products meet strict hygiene standards. Others may offer rapid prototyping and custom-design services, appealing to customers with unique requirements. This diversity in the market creates a highly competitive environment, where each manufacturer must continuously innovate and make strategic decisions to stay ahead.

Factors Influencing Rotary Union Manufacturers’ Choices

Product-related Factors

Performance Requirements

Performance is the cornerstone of any rotary union, and manufacturers must carefully consider a multitude of parameters when designing and developing their products. The rotational speed is a critical factor, as different applications require rotary unions to operate at varying speeds. In high-speed printing presses, for instance, rotary unions need to be able to handle speeds of up to 1000 revolutions per minute (RPM) or more to ensure smooth and continuous ink transfer.

Operating pressure is another crucial consideration. In hydraulic systems used in construction equipment or industrial machinery, rotary unions may need to withstand pressures of several thousand pounds per square inch (PSI). Failure to meet the required pressure ratings can result in leaks, reduced performance, and even catastrophic equipment failure.

Temperature tolerance is also vital, especially in applications where extreme temperatures are involved. In the aerospace industry, rotary unions used in engine components must be able to withstand the intense heat generated during flight, while in cryogenic applications, such as liquefied natural gas (LNG) processing, they need to function properly at extremely low temperatures.

Material Selection

The choice of material for rotary unions can make or break their performance and lifespan. Corrosion resistance is a key property, particularly for applications in industries such as chemical processing, marine, and food and beverage. Stainless steel is a popular choice due to its excellent corrosion-resistant properties. It can withstand the harsh chemicals and moisture commonly found in these environments, ensuring the longevity of the rotary union.

For high – temperature applications, materials like Inconel, a nickel – based alloy, are preferred. Inconel can maintain its strength and integrity at temperatures up to 2000°F (1093°C), making it suitable for use in aerospace engines, power generation turbines, and other high – heat applications.

However, material selection is not just about performance; cost – effectiveness also plays a significant role. Manufacturers need to balance the need for high – quality materials with the overall cost of production. For example, while exotic materials may offer superior performance, they can also be prohibitively expensive. In some cases, manufacturers may opt for alternative materials or material combinations that can provide a good balance between performance and cost.

Product Design and Innovation

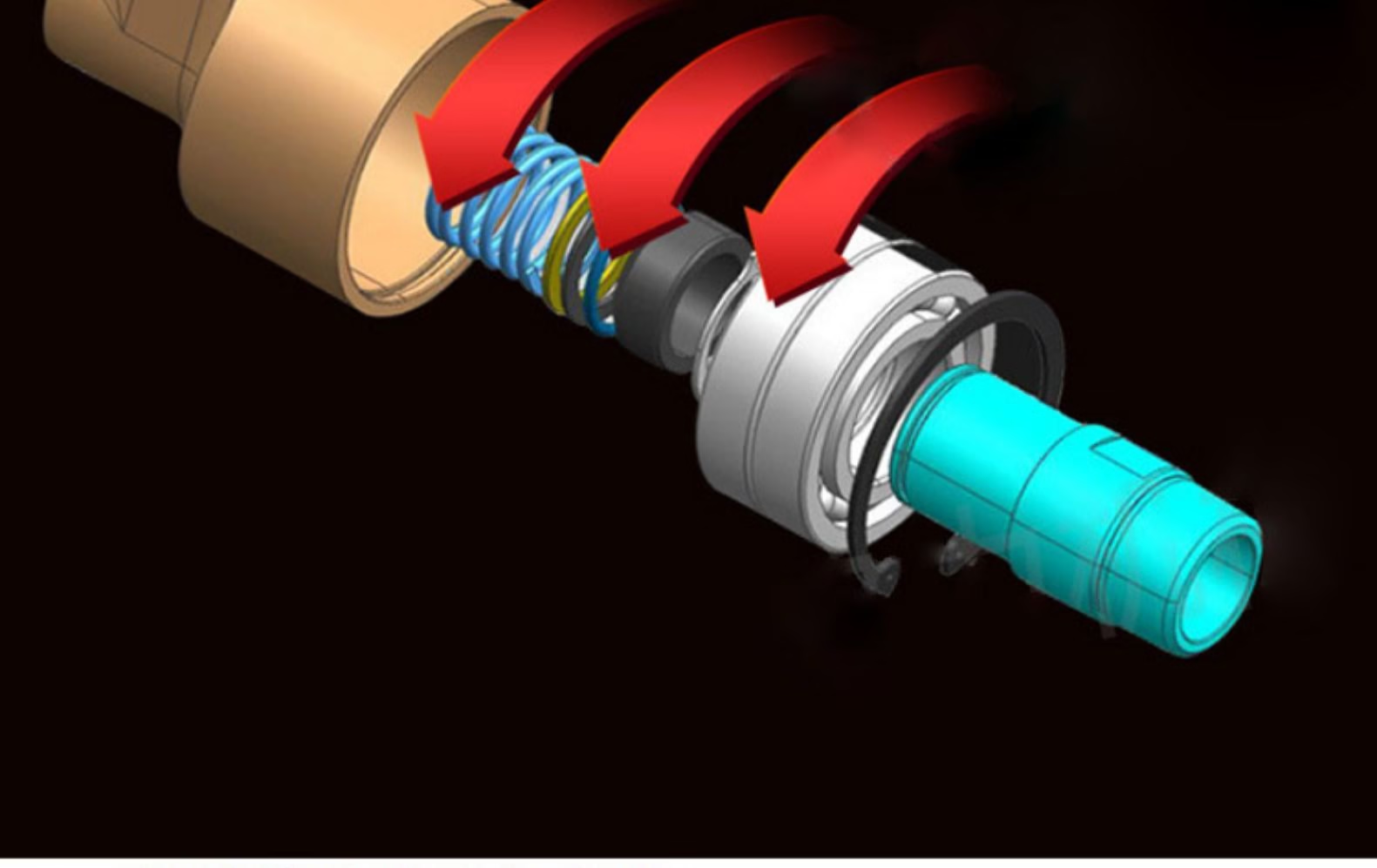

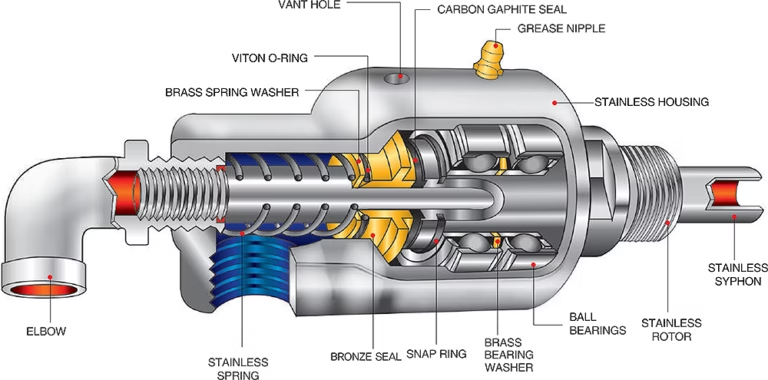

In today’s competitive market, product design and innovation are essential for manufacturers to gain a competitive edge. New seal designs can greatly enhance the leak – proofing capabilities of rotary unions. For example, some manufacturers are now using double – lip seals with advanced materials and geometries to prevent fluid leakage even under high – pressure and high – speed conditions.

Optimized structures can also improve the overall efficiency of rotary unions. By reducing internal friction and improving fluid flow paths, manufacturers can minimize energy losses and increase the performance of their products. For instance, some rotary unions feature streamlined internal channels that reduce turbulence and pressure drop, resulting in more efficient fluid transfer.

In addition, the development of intelligent rotary unions is an emerging trend. These unions are equipped with sensors that can monitor parameters such as temperature, pressure, and vibration in real time. This data can be used to predict maintenance needs, optimize performance, and prevent unexpected failures, providing significant value to customers.

Supplier-related Factors

Supplier Reputation and Reliability

A supplier’s reputation for delivering high – quality materials on time is non – negotiable for rotary union manufacturers. Any delay in the supply of critical components can have a domino effect on the production process. For example, if a manufacturer is waiting for a shipment of specialized seals and the supplier fails to deliver on schedule, it can lead to production downtime, missed customer deadlines, and damaged relationships.

Reliability also extends to the quality of the materials supplied. Substandard materials can result in defective rotary unions, which can then lead to costly recalls, repairs, and loss of customer trust. Therefore, manufacturers typically conduct thorough due diligence before choosing a supplier, including reviewing their quality control processes, customer references, and industry reputation.

Cost-effectiveness of Supplies

Cost is a significant factor in the supplier selection process, but it cannot be the sole determinant. Manufacturers need to find a balance between the price of supplies and the quality of the final product. Negotiating long – term contracts with suppliers can often result in cost savings, as it provides stability and volume discounts.

Exploring alternative materials or suppliers can also be a cost-effective strategy. For example, if the price of a particular raw material increases significantly, manufacturers may look for substitute materials that offer similar performance at a lower cost. However, this requires careful evaluation to ensure that the substitution does not compromise the quality or functionality of the rotary union.

Supplier’s R&D Capability and Technical Support

Suppliers with strong research and development capabilities can be invaluable partners for rotary union manufacturers. They can collaborate on the development of new materials, components, and manufacturing processes, helping manufacturers stay at the forefront of technological advancements. For example, a supplier may work with a manufacturer to develop a new type of seal material that offers improved performance and durability.

Technical support is also crucial. Suppliers that can provide on-site troubleshooting, training, and technical advice can help manufacturers minimize downtime and ensure the smooth operation of their production lines. In addition, they can assist with the integration of new products or technologies, reducing the learning curve for manufacturers.

Customer-related Factors

Meeting Diverse Customer Needs

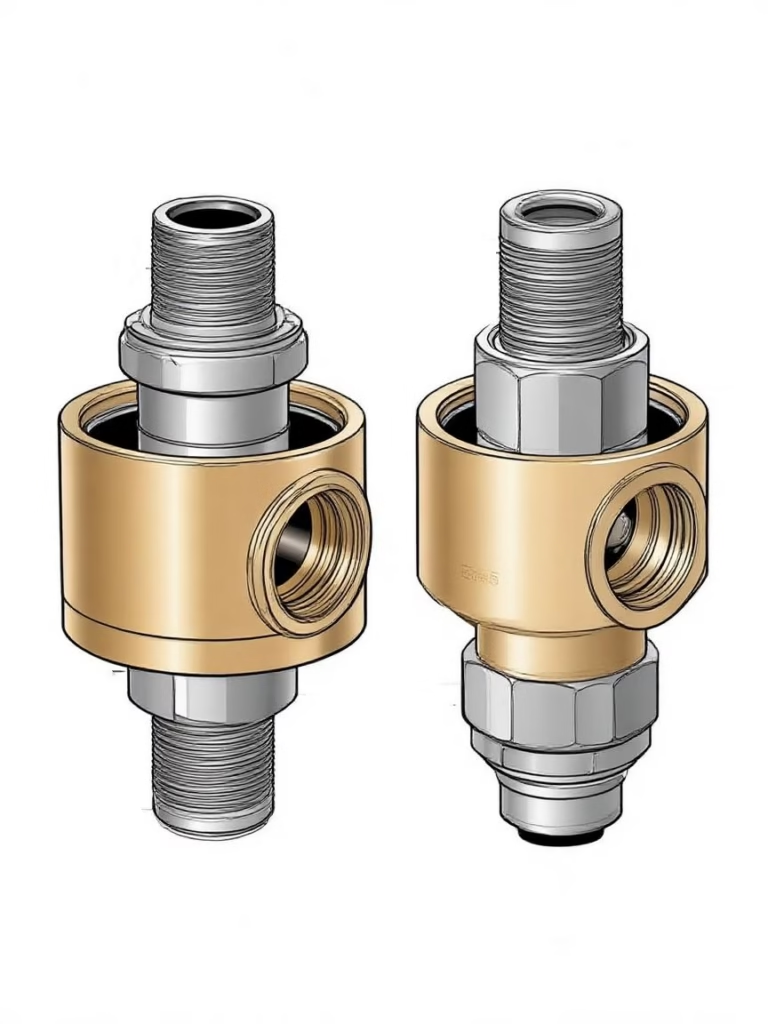

Customers from different industries have unique and diverse needs when it comes to rotary unions. In the paper manufacturing industry, for example, customers may require rotary unions that can handle large-volume fluid transfer at high flow rates. These unions need to be able to withstand the abrasive nature of paper pulp and the high-pressure conditions in the manufacturing process.

In the medical device industry, on the other hand, precision and cleanliness are of utmost importance. Rotary unions used in medical equipment must meet strict regulatory standards, such as those set by the Food and Drug Administration (FDA) in the United States. They need to have precise flow control capabilities and be made from materials that are biocompatible and easy to clean, and sterilize.

Manufacturers must have a deep understanding of these industry – specific requirements and be able to develop products that meet or exceed customer expectations. This may involve customizing the design, materials, and performance characteristics of their rotary unions to suit the unique needs of each customer.

Customer Expectations on Quality and Price

Customers expect high – quality products at competitive prices. To meet these expectations, manufacturers need to invest in quality control measures at every stage of the production process. This includes raw material inspection, in – process quality checks, and final product testing. By ensuring that their products meet strict quality standards, manufacturers can build a reputation for reliability and quality, which is essential for customer retention.

At the same time, manufacturers also need to manage costs effectively to offer competitive prices. This requires continuous process improvement, lean manufacturing practices, and efficient supply chain management. By optimizing their operations and reducing waste, manufacturers can lower their production costs without sacrificing quality, allowing them to offer more competitive pricing to their customers.

Case Studies of Successful Choices by Rotary Union Manufacturers

Case 1: A Leading Manufacturer’s Material Choice

A well-known rotary union manufacturer faced a challenge in improving the performance of its high-performance rotary unions for the aerospace industry. The existing materials were not able to withstand the extreme temperatures and high rotational speeds required by the latest generation of aircraft engines.

After extensive research and development, the manufacturer decided to switch to a new type of composite material. This material had a superior strength – to – weight ratio, which could significantly improve the performance of the unions in high – speed applications. The manufacturer worked closely with a supplier to develop the composite material, ensuring that it met the strict requirements of the aerospace industry.

The implementation process involved a phased approach. First, the new material was tested in a laboratory setting to validate its performance. Then, small – scale production runs were conducted to fine – tune the manufacturing process. Finally, the new rotary unions were introduced into the market.

The results were remarkable. The manufacturer saw a 20% increase in product efficiency, as the new material reduced internal friction and improved fluid transfer. Maintenance costs were also reduced by 15%, as the improved durability of the material minimized the need for frequent replacements.

Case 2: Another Manufacturer’s Supplier Selection

Another rotary union manufacturer was looking to expand its product line to include rotary unions for the emerging electric vehicle (EV) battery manufacturing industry. The manufacturer needed a supplier that could provide high-quality, customized components with quick turnaround times to meet the fast-paced demands of the EV market.

After a thorough evaluation of several potential suppliers, the manufacturer chose to partner with a new supplier known for its innovative production processes. The supplier had a state – of – the – art manufacturing facility equipped with advanced 3D printing and CNC machining technologies, which allowed for rapid prototyping and customization of components.

The partnership proved to be a game-changer. The supplier’s ability to offer customized components and quick turnaround times helped the manufacturer meet the urgent needs of a major EV battery manufacturer. The manufacturer was able to develop a new line of rotary unions specifically designed for the EV battery manufacturing process, which included features such as high-precision fluid control and leak-proof seals.

As a result, the manufacturer not only secured a long-term contract with the customer but also enhanced its reputation in the market for its responsiveness and flexibility. The success of this partnership also opened up new opportunities for the manufacturer in other emerging industries.

Future Outlook for Rotary Union Manufacturers’ Choices

Emerging Trends in the Industry

The rotary union industry is on the cusp of several exciting trends. The increasing demand for smart and connected industrial equipment is driving the development of intelligent rotary unions. These unions will be equipped with sensors and communication modules that can collect and transmit data in real time. This data can be used for predictive maintenance, performance optimization, and remote monitoring, providing significant value to customers.

The growing focus on sustainability is also influencing the industry. Manufacturers are increasingly looking for ways to reduce the environmental impact of their products and production processes. This includes using more environmentally friendly materials, such as recycled plastics and bio-based polymers, and developing energy-efficient designs. In addition, there is a growing trend towards circular economy principles, where products are designed for disassembly, recycling, and reuse.

How Manufacturers Can Adapt Their Choices

To adapt to these emerging trends, manufacturers need to invest in research and development. They should explore new technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and blockchain, to develop innovative products and services. For example, by integrating IoT sensors into rotary unions, manufacturers can offer customers real-time monitoring and analytics services, enhancing the value of their products.

FAQ – Common Challenges Solved

Q: Why do my unions fail prematurely?

A: Misalignment is the #1 cause. Specify units with spherical bearings or floating seals.

Q: Can I retrofit a union to an existing machine?

A: Yes, but ensure reverse engineering of shaft tolerances and finite element analysis of loading.

Q: What’s the ROI of premium unions?

A: A 5,000 high-quality union may save 200,000 in downtime over 5 years.

Conclusion: Partnering for Success

Selecting a rotary union manufacturer isn’t just a purchase—it’s a strategic partnership. Prioritize suppliers who offer:

Vertical integration (in-house machining/testing)

Transparent pricing models

Sustainability initiatives

Call to Action

Ready to optimize your rotary union procurement? Contact us for customized items matching your specific needs.