In-Depth Analysis of the Sector Embedded Rotary Joint

In the era of intelligent manufacturing and precision automation, the demand for efficient and stable fluid transfer between rotating and stationary components has risen sharply. The embedded rotary joint, also known as an embedded rotary union, has emerged as a key component in achieving this goal.

Unlike traditional rotary unions, which are externally mounted, the sector embedded rotary joint is integrated directly into the rotating structure of equipment, reducing space requirements while improving sealing performance and rotational stability.

This article provides an in-depth analysis of the structural principles, operating mechanisms, and real-world applications of sector-embedded rotary joints. It also offers engineering insights for equipment designers and procurement specialists seeking cost-effective and durable rotary joint solutions.

Table of Contents

-

Structural Overview of Embedded Rotary Joint

-

Working Principle Explained

-

Key Components and Material Selection

-

Sealing Technology and Leakage Prevention

-

Advantages of Sector-Embedded Rotary Joint

-

Application Fields and Industry Use Cases

-

Installation Considerations and Maintenance

-

Selection Guide for Engineers and Buyers

-

Future Development Trends

-

Conclusion

1. Structural Overview of Embedded Rotary Joint

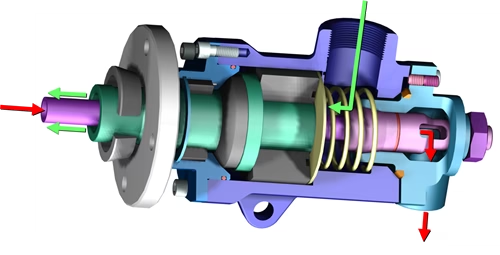

An embedded rotary joint consists of a precision-engineered assembly that allows the transfer of media—such as air, oil, water, or coolant—between a stationary source and a rotating element without leakage.

Unlike traditional flange-mounted rotary unions, this type is embedded within the host equipment’s housing or shaft, forming a compact, integrated structure.

Key structural components include:

-

Housing (Body): Usually machined from high-strength stainless steel or aluminum alloy for durability and corrosion resistance.

-

Rotor/Shaft: The rotating part connected to the equipment’s main spindle or arm.

-

Sealing Assembly: Precision seals that separate media passages and prevent leakage.

-

Bearings: High-speed bearings ensure smooth rotation with minimal friction.

-

Passages (Channels): Internal channels for fluid or gas transfer.

2. Working Principle Explained

The working principle of the embedded rotary joint is based on relative motion between the stationary and rotating parts while maintaining a sealed fluid path.

When media (e.g., compressed air or hydraulic oil) enters through the stationary port, it travels through internal channels to the rotating outlet. The sealing system ensures that no leakage occurs even under high-speed or high-pressure conditions.

Key operational principles:

-

Static-to-Rotary Conversion: Enables transfer without pipe twisting.

-

Balanced Sealing Force: Ensures consistent contact pressure and minimal wear.

-

Self-lubricating Design: Reduces friction and extends service life.

3. Key Components and Material Selection

The performance of a sector-embedded rotary joint depends heavily on the quality of its core materials.

| Component | Recommended Material | Function |

|---|---|---|

| Housing | Stainless steel 304/316 | Strength, corrosion resistance |

| Shaft | Hardened tool steel | Rotational precision |

| Seals | Carbon graphite / Silicon carbide | Leak prevention under pressure |

| Bearings | Hybrid ceramic or stainless | Smooth, low-friction rotation |

Material selection must consider working pressure, rotational speed, media type, and operating temperature. For instance, silicon carbide seals perform well under corrosive or high-temperature conditions, while graphite seals excel in dry-running environments.

4. Sealing Technology and Leakage Prevention

Sealing technology is the heart of rotary joint design. In embedded rotary joints, engineers often utilize mechanical face seals or non-contact seals to meet various operational demands.

Types of sealing structures:

4.1 Contact-type (Mechanical Seal): Provides a tight seal using spring-loaded carbon and carbide faces. Ideal for low-speed, high-pressure applications.

4.2 Non-contact type: Uses fluid film or aerodynamic principles to create a micro-gap seal—suitable for high-speed rotary joints where frictional heat must be minimized.

5. Advantages of Sector-Embedded Rotary Joint

The sector embedded design integrates the rotary joint directly into the system housing, offering several engineering and performance advantages:

-

Compact structure: Reduces installation space and system weight.

-

Improved stability: Embedded design minimizes vibration and misalignment.

-

Enhanced sealing performance: Reduces exposure to external contaminants.

-

Simplified maintenance: Modular components allow easy disassembly and replacement.

-

Higher reliability: Suitable for long-term continuous operation.

6. Application Fields and Industry Use Cases

Engineers employ embedded rotary joints to efficiently transfer fluids or gases between rotating and stationary components, ensuring leak-free operation even under high-pressure and speed conditions. By integrating advanced sealing technology and precision-engineered channels, these rotary joints enable continuous media transmission while maintaining system stability and reducing maintenance frequency. As a result, they play a critical role in modern automation, CNC machinery, and robotic applications, where reliability and performance are paramount. Common applications include:

6.1 Papermaking Machinery: The “Steam Circulation Hub” of the Drying Cylinder Group

Engineers heat dozens of drying cylinders with steam, maintaining temperatures between 120°C and 180°C. The system operates under pressures ranging from 0.3 to 0.8 MPa to ensure efficient heat transfer. Meanwhile, technicians circulate cooling water through the inner walls to prevent paper web adhesion. Traditional externally mounted rotary joints are bulky, occupying the narrow space between the drying cylinders (spacing is only 150-200 mm), and have poor sealing reliability, resulting in steam leakage rates exceeding 5%, leading to energy waste.

The embedded sector rotary joint features a 40% smaller design and can be directly embedded into the dryer shaft, fitting into confined spaces. Its composite sealing structure reduces steam leakage to less than 0.5%, saving approximately 100,000 cubic meters of steam energy per year for a single papermaking machine. Engineers design the joint’s media channels separately to isolate steam and cooling water. This separation effectively prevents hot and cold media from mixing, avoiding unwanted temperature fluctuations. As a result, the drying cylinder maintains a uniform surface temperature, with a difference of no more than 2°C. This stability improves paper drying quality and significantly reduces production scrap.

6.2 Wind Power Generation: The “Hydraulic Control Core” of the Pitch Control System

The pitch control system of a wind turbine uses hydraulic oil to drive the pitch motor, adjusting the blade angle to adapt to varying wind speeds (hydraulic oil pressure 10-15 MPa, speed ≤ 30 r/min). Wind turbines operate in outdoor environments, exposed to temperature fluctuations of -30°C to 60°C, strong winds, sandstorms, and salt spray (for coastal wind power). Traditional rotary joints are susceptible to aging seals and rust, resulting in a service life of only 6-12 months.

Engineers build the housing of the embedded sector rotary joint from 316 stainless steel for corrosion resistance. This material effectively withstands salt spray and harsh marine environments. They use low-temperature-resistant fluororubber seals, which remain flexible even at -40°C. In addition, sealed deep-groove ball bearings protect the joint from wind and sand intrusion. These design choices extend the service life to two or three years. As a result, maintenance downtime is greatly reduced compared with traditional rotary joints. Conventional joints require one or two maintenance cycles per year. However, embedded rotary joints need servicing only once every three years. This improvement significantly increases fan operating efficiency and reliability.

6.3 Plastic calender: The key to temperature control of the calender roller

Plastic calenders are used to produce plastic film or sheet. The calender rollers must be heated by hot oil (temperature 160-200°C, pressure 1.5-2MPa), and extremely high temperature control accuracy (±1°C) is required. Otherwise, uneven film thickness will occur (a deviation of 0.02mm or more will be rejected). The inner wall of the hot oil channel of the embedded sector rotary joint is finely polished (Ra ≤ 0.4μm), reducing resistance to hot oil flow and preventing temperature fluctuations caused by local turbulence. Its self-compensating seal ensures no hot oil leakage, preventing contamination of the plastic raw material. Furthermore, a built-in temperature sensor monitors the hot oil temperature in real time and provides feedback to the control system to adjust the heating power, ensuring uniform surface temperature on the calendering rolls and controlling film thickness deviation within 0.01mm, thereby increasing product qualification rates to over 99%.

6.4 Port Cranes: “Hydraulic Power Transmitters” for Slewing Mechanisms

Engineers drive the slewing mechanisms of port container cranes with hydraulic oil, maintaining pressures between 20 and 25 MPa. This system enables the crane boom to rotate 360°, while operating at speeds up to 10 r/min. Port environments are subject to strong salt spray and sea spray. Traditional rotary joints are prone to rusting the housing and aging of seals, leading to hydraulic oil leakage and affecting the accuracy of the slewing motion.

The embedded sector rotary joint is constructed entirely of stainless steel (316L housing, 304 sleeve), achieving salt spray corrosion resistance of C5-M (ISO 12944 standard). The seal is made of silicon carbide ceramic, which is wear-resistant and high-pressure resistant. The joint also features a dust cover to prevent the ingress of sea spray. Its hydraulic oil leakage rate is ≤0.1L/h, and its rotary accuracy is improved to ±0.5°, meeting the precise positioning requirements for container loading and unloading.

7. Installation Considerations and Maintenance

Proper installation is vital to ensure performance and service life.

Engineers should pay attention to:

-

Alignment between the rotary joint and the rotating shaft

-

Clean and lubricated sealing surfaces

-

Adequate clearance for thermal expansion

-

Regular inspection of bearing wear and seal condition

Maintenance tips:

-

Replace seals at recommended intervals.

-

Avoid dry-running to prevent seal damage.

-

Use compatible fluids to prevent corrosion.

8. Selection Guide for Engineers and Buyers

When selecting a sector embedded rotary joint, engineers and procurement specialists should evaluate:

-

Operating parameters: Pressure, temperature, and rotational speed.

-

Media type: Water, air, oil, steam, or coolant.

-

Passage configuration: Single, dual, or multi-passage rotary unions.

-

Material compatibility: Based on corrosion and wear conditions.

-

Maintenance accessibility: Ease of replacement and lubrication.

Tip: For OEM machinery design, embedded rotary joints can be customized to match the host equipment’s housing dimensions and media channels—offering seamless integration and superior reliability.

9. Future Development Trends

As industrial automation evolves, embedded rotary joints will continue to develop toward:

-

Miniaturization and modularity for compact machinery

-

Smart monitoring using embedded sensors for temperature and leakage detection

-

Enhanced material technology (e.g., diamond-like coatings for seals)

-

Multi-channel integration for simultaneous transfer of multiple fluids or electrical signals

10. Conclusion

The sector embedded rotary joint represents a significant advancement in fluid transfer technology. Its compact structure, high reliability, and customizable design make it indispensable in modern CNC machines, robotics, and automation systems.

For engineers and buyers, understanding its structural principle and sealing mechanism helps optimize performance, reduce maintenance costs, and ensure stable long-term operation.

Whether applied in high-speed machining or precision robotic arms, the embedded rotary joint continues to set new standards for efficiency, safety, and durability in rotating fluid systems.