What is a Rotary Union?

A rotary union, also known as a rotating union or swivel joint, is a critical mechanical component designed to facilitate the transfer of fluids, gases, or signals between stationary and rotating parts of machinery. This device plays a pivotal role in various industrial applications, ensuring continuous operation and efficiency in systems that require fluid or gas transfer during rotation.

In the world of engineering and industrial applications, rotary unions play a crucial role in ensuring the smooth transfer of fluid or gas between stationary and rotating parts. These essential components are commonly used in machinery, automation, and a variety of systems that require the uninterrupted flow of media. In this guide, we will explore everything you need to know about rotary unions, from their definition to their types, working principles, applications, and much more.

What is a Rotary Union?

A rotary union (also known as a rotary joint or swivel joint) is a mechanical device designed to transfer fluids (water, steam, oil, air, etc.) from a stationary source to a rotating part. These unions are typically used in machinery or equipment where the parts are subject to continuous rotational motion. By allowing the transfer of media without causing leaks or disruptions, rotary unions ensure the seamless operation of rotating systems.

Rotary unions are versatile devices used across multiple industries, including manufacturing, aerospace, automotive, and construction. They are essential for maintaining the integrity of fluid or gas flow in rotating machinery, such as drums, cylinders, or spindles. The primary function of a rotary union is to provide a seal between a stationary supply passage and a rotating component, allowing the flow of media like steam, water, hydraulic fluid, or coolants into and out of the rotating part.

Rotary unions are especially vital in industrial machinery, automation systems, robotic arms, and even in medical devices where high precision is required. A rotary union is constructed in such a way that it prevents fluid leakage while providing a reliable connection between stationary and rotating parts.

1.1 Key Components of Rotary Unions

1.1 Key Components of Rotary Unions

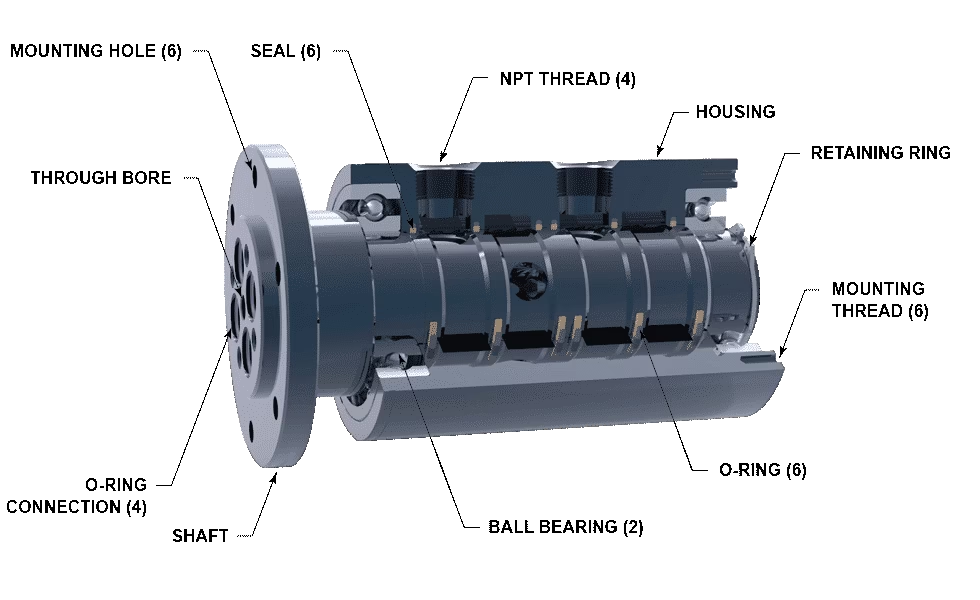

A rotary union consists of four fundamental components:

Housing: This is the outer casing that encloses all other parts of the rotary union. It features inlet and outlet ports for connecting hoses or pipes that supply and remove the fluid or gas.

Shaft: The central component that carries the fluid or gas through the rotary union into the rotating part. In many designs, the shaft rotates with the drum or cylinder.

Bearings: These are crucial for supporting the shaft’s rotation, reducing friction, and ensuring smooth operation. Common types include ball bearings, roller bearings, and non-roller bearings like graphite or bronze bushings.

Seals: The heart of the rotary union, seals prevent media leakage during operation. Various seal types are used, including pusher-type end-face mechanical seals, non-pusher-type end-face mechanical seals, lip seals, and O-ring seals.

1.2 Key Features of Rotary Unions

1.2 Key Features of Rotary Unions

Leak-Proof Fluid Transfer: The primary function of a rotary union is to provide a leak-free connection for fluid or gas transfer.

Rotational Motion: It allows for continuous rotation of the connected components.

Durability: Rotary unions are designed to withstand the wear and tear of continuous use in harsh environments.

Versatility: They can handle a variety of fluids including water, air, oil, steam, and hydraulic fluids.

1.3 How Does a Rotary Union Work?

A rotary union typically consists of two key components: the stationary part (usually the housing) and the rotating part (the rotor). The fluid or gas enters the stationary part of the union and is then transferred to the rotating part through a sealed interface. This design prevents leaks while maintaining a continuous flow of media, regardless of the rotational movement.

The process works as follows:

Fluid Entry: The fluid or gas enters through the inlet port on the stationary part.

Transfer Mechanism: The fluid flows through the union and is directed to the rotating part.

Sealing: The rotary union incorporates mechanical seals to ensure that the fluid does not leak during the transfer process.

Rotational Motion: As the rotating component turns, the fluid continues to flow seamlessly through the union, without interruptions.

This mechanism is essential in various industries, particularly those involving high-speed or high-pressure systems.

Different Types of Rotary Unions

There are several types of rotary unions, each designed to meet specific industrial needs. The choice of rotary union depends on factors such as the type of media being transferred, the pressure and temperature conditions, the rotational speed, and the number of passages required.

1. Water Rotary Unions

Water rotary unions designed for applications that require the transfer of water between stationary and rotating parts. These unions are commonly used in industries such as paper manufacturing, cooling systems, and metalworking.

2. Steam Rotary Unions

2. Steam Rotary Unions

Steam rotary unions built to handle high-temperature and high-pressure steam. They are commonly used in power plants, textile manufacturing, and food processing industries.

3. Air Rotary Unions

These air rotary unions designed for transferring compressed air. They are ideal for applications in pneumatic tools, robotic arms, and industrial automation.

4. Oil Rotary Unions

Oil rotary unions used to transfer oils and lubricants in systems that require continuous lubrication or temperature control. These unions often found in metalworking, plastics, and automotive manufacturing industries.

5. Hydraulic Rotary Unions

Hydraulic rotary unions specifically designed to handle high-pressure hydraulic systems. They widely used in construction machinery, material handling equipment, and agricultural machinery.

6. High-Pressure Rotary Unions

High-pressure rotary unions built to withstand extreme pressures, often up to 10,000 PSI or more. They used in oil drilling, chemical processing, and high-pressure hydraulic systems.

7. High-Speed Rotary Union

The high speed rotary union designed for applications requiring high rotational speeds, these unions employ advanced bearing and sealing systems to withstand centrifugal forces and heat generated during rapid rotation.

8. High-Temperature Rotary Union

The high temperature rotary union specialized for applications involving elevated temperatures, these unions incorporate materials and cooling mechanisms to prevent overheating while maintaining efficient fluid transfer.

9. Through-Bore Rotary Union

Featuring a hollow center, these unions allow for the passage of fluids, gases, or electrical signals through the joint’s central axis. They are valuable in applications requiring media transmission through a rotating structure.

10. Single Passage Rotary Union

This basic single passage type rotary union provides a single flow channel for transferring one type of fluid or gas. It widely used in applications requiring the transfer of a single medium, such as water, air, or hydraulic fluid.

11. Multi-Passage Rotary Unions

These multi-passager rotary unions can handle multiple types of media simultaneously through separate channels. These unions feature multiple flow channels, enabling the simultaneous transfer of different fluids or gases. They are essential in complex systems that require separate circuits for various media types. They are essential in systems that require the transfer of different fluids, such as robotic systems, automated manufacturing, and injection molding machines.

12. Mechanical Seal Rotary Unions

Design: Use two precision-machined faces (one rotating, one stationary) pressed together by springs or magnetic forces.

Materials: Tungsten carbide (for high hardness), silicon carbide (for corrosion resistance), or carbon graphite (for low friction).

Applications:

High-temperature steam systems (up to 600°C) in power plants or paper mills.

High-pressure hydraulic systems in construction machinery.

Sanitary applications in food processing (316L stainless steel faces).

Advantages: Excellent leak resistance; suitable for high speeds (up to 10,000 RPM) and harsh media.

Disadvantages: Sensitive to particulate contamination; requires clean fluids.

13. Packing Seal Rotary Unions

Design: Use compressible materials like braided graphite, asbestos (now phased out), or PTFE packing around the rotor to create a seal.

Adjustment: Gland nuts tighten the packing to compensate for wear.

Applications:

Low-pressure water or air systems (e.g., agricultural irrigation, older industrial pumps).

Simple machinery with minimal speed (≤500 RPM) and pressure (≤100 PSI).

Advantages: Cost-effective; easy to replace packing material.

Disadvantages: Higher friction (causing energy loss); prone to leakage at high speeds or pressures.

14. Magnetic Seal Rotary Unions

Design: Use magnetic coupling to align sealing faces without mechanical springs, enabling contactless sealing.

Materials: Neodymium magnets for strong, stable force; non-magnetic housings (e.g., aluminum) to avoid interference.

Applications:

Vacuum systems in semiconductor manufacturing (leak-free in low-pressure environments).

Sterile pharmaceutical equipment (no particle generation from mechanical wear).

Advantages: Reduced wear; ideal for clean or sensitive media.

Disadvantages: Limited to low torque and moderate speeds; risk of magnetic field interference.

Applications of Rotary Unions

Rotary unions used across a wide range of industries. Some common applications include:

Industrial Automation: Rotary unions are crucial in automated assembly lines, robotic arms, and other automated machinery that require fluid or air transfer while rotating.

Machine Tools: CNC machines, lathes, and milling machines often use rotary unions to transfer hydraulic fluid, cooling fluids, or lubricants to rotating parts.

Paper Manufacturing: Rotary unions used in paper mills to transfer water or steam to rotating drums and equipment.

Energy & Power Generation: Power plants rely on rotary unions for transferring steam, water, and oil to rotating turbines and generators.

Food and Beverage Processing: Rotary unions used in systems that need high-temperature steam transfer for sterilization or cooking.

Key Considerations When Choosing a Rotary Union

When selecting a rotary union for a specific application, there are several factors to consider:

Fluid Type: Make sure the union is compatible with the fluid transferred (water, air, oil, steam, etc.).

Operating Pressure and Temperature: Choose a union that can handle the pressure and temperature requirements of the application.

Rotational Speed: Ensure that the rotary union is capable of withstanding the rotational speed of the system.

Sealing Mechanism: Consider the type of seal used in the rotary union to prevent leakage and ensure reliable operation.

Material Compatibility: Ensure that the materials used in the rotary union are suitable for the environment and media transferred.

Benefits of Rotary Unions

Rotary unions offer a range of benefits that contribute to the efficiency and longevity of industrial systems:

Leak-Proof Operation: Rotary unions provide a reliable, leak-free connection for transferring fluids, ensuring minimal downtime and maintenance.

Reduced Wear and Tear: The design of rotary unions minimizes friction between moving parts, reducing the risk of wear and damage.

Increased Efficiency: By ensuring uninterrupted fluid flow, rotary unions help improve the overall performance and efficiency of machinery.

Versatility: Rotary unions can handle a wide range of fluids, including water, oil, steam, and air, making them suitable for a variety of industries.

Challenges and Maintenance of Rotary Unions

Despite their benefits, rotary unions are subject to wear and tear, especially when operating under high-pressure or high-temperature conditions. Proper maintenance is essential to ensure their continued performance.

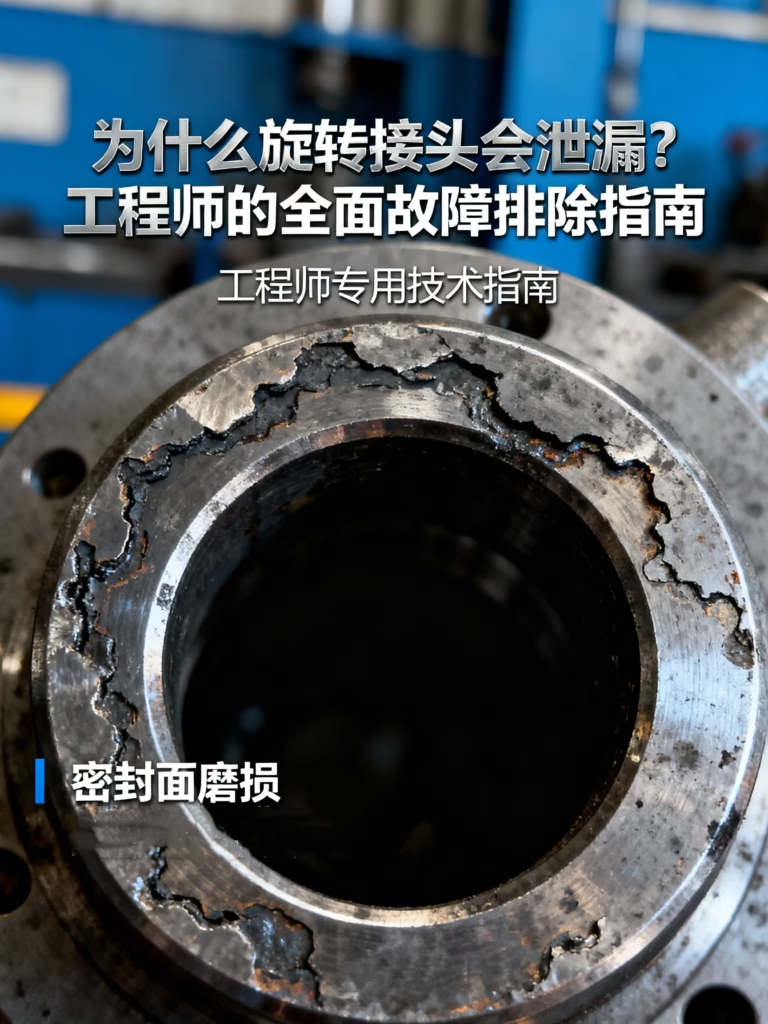

Common challenges include

Seal Failure: Over time, seals can wear out, leading to fluid leakage. Regular inspection and replacement of seals are necessary.

Clogging: Over time, contaminants in the fluid can clog the rotary union. Proper filtration systems can help reduce this issue.

Temperature and Pressure Fluctuations: Extreme fluctuations in temperature and pressure can damage the rotary union. Monitoring and controlling these parameters is essential.

Regular maintenance, including lubrication and cleaning, can extend the life of a rotary union and improve its efficiency.

Emerging Trends in Rotary Union Technology

Integration of Smart Sensors

Rotary unions are increasingly integrate with smart sensors and IoT technology to enable real-time performance monitoring and predictive maintenance, reducing downtime and enhancing reliability56.

Advancements in Seal Technology

Modern rotary unions feature advanced seals made from high-performance materials like graphite, carbon, and ceramics, offering superior resistance to wear and corrosive environments.

Focus on Energy Efficiency

Designs are being optimized to reduce energy consumption through low-friction components and optimized flow paths, contributing to sustainable and cost-effective operations.

Customization and Application-Specific Designs

Manufacturers are offering tailored solutions with adjustable features to meet specific industry needs, enhancing versatility and effectiveness in diverse applications6.

Conclusion

A rotary union is an essential component in various industrial systems, allowing for the transfer of fluids from stationary to rotating parts while maintaining a leak-free connection. From water rotary unions to high-pressure hydraulic systems, there are various types of rotary unions to meet the demands of different applications. By understanding how rotary unions work, their types, and key considerations when selecting one, engineers and industrial professionals can make informed decisions to optimize their machinery and operations.

If you need a rotary union for your system, it’s crucial to choose the right type based on your fluid needs, system pressure, and temperature conditions. Regular maintenance and timely replacements can also ensure that your rotary union operates at peak efficiency for years to come.

For more in-depth resources on industrial machinery and fluid transfer solutions, subscribe to our blog or contact our experts for customized recommendations.