Expert Guide: Effectively Offering Rotary Union for Sale in Manufacturing Industry

In the intricate web of the manufacturing industry, rotary union swivel joints serve as the unsung heroes that ensure the seamless operation of countless industrial processes. As a seasoned expert in the manufacturing field, I understand the nuances and challenges associated with offering these essential components for sale. In this comprehensive 3000-word blog post. I will share in-depth insights, practical strategies, and industry-specific knowledge to help you effectively promote and sell rotary unions in a highly competitive market.

The Significance of Rotary Union Swivel Joints in Manufacturing

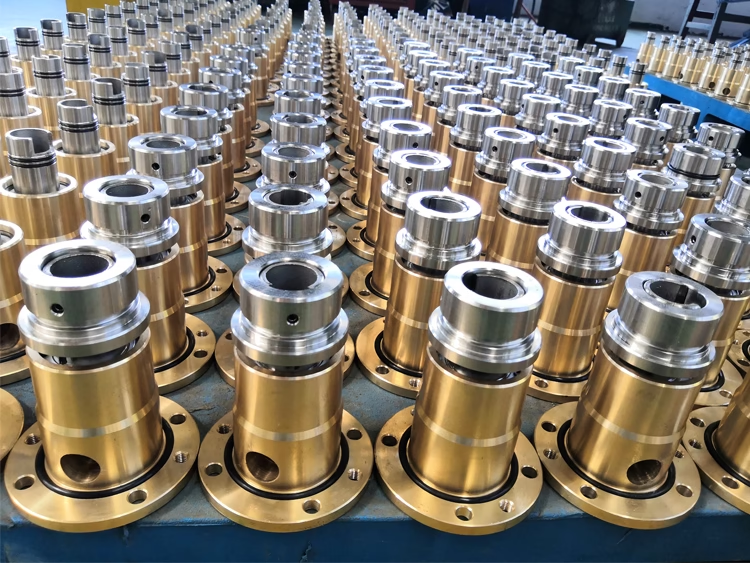

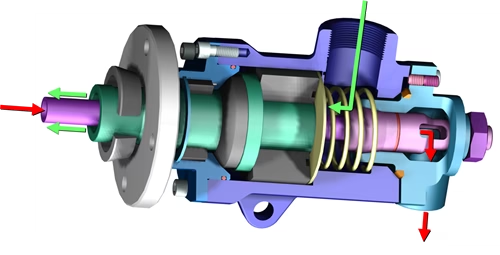

Core Functionality and Technical Insights

Rotary union swivel joints are engineering marvels designed to enable the transfer of various media. Including fluids (such as hydraulic oil, coolant, and water), gases, and even electrical power, between the stationary and rotating parts of machinery. Their functionality is based on a combination of precision-engineered seals, bearings, and housings. For instance, in a high-speed CNC machining center. Rotary union swivel joint must maintain a leak-proof seal while facilitating the continuous flow of coolant to the cutting tool, even at rotational speeds of several thousand RPM. The choice of seal materials, such as PTFE or silicone, depends on factors like the chemical compatibility of the fluid being transferred and the operating temperature and pressure.

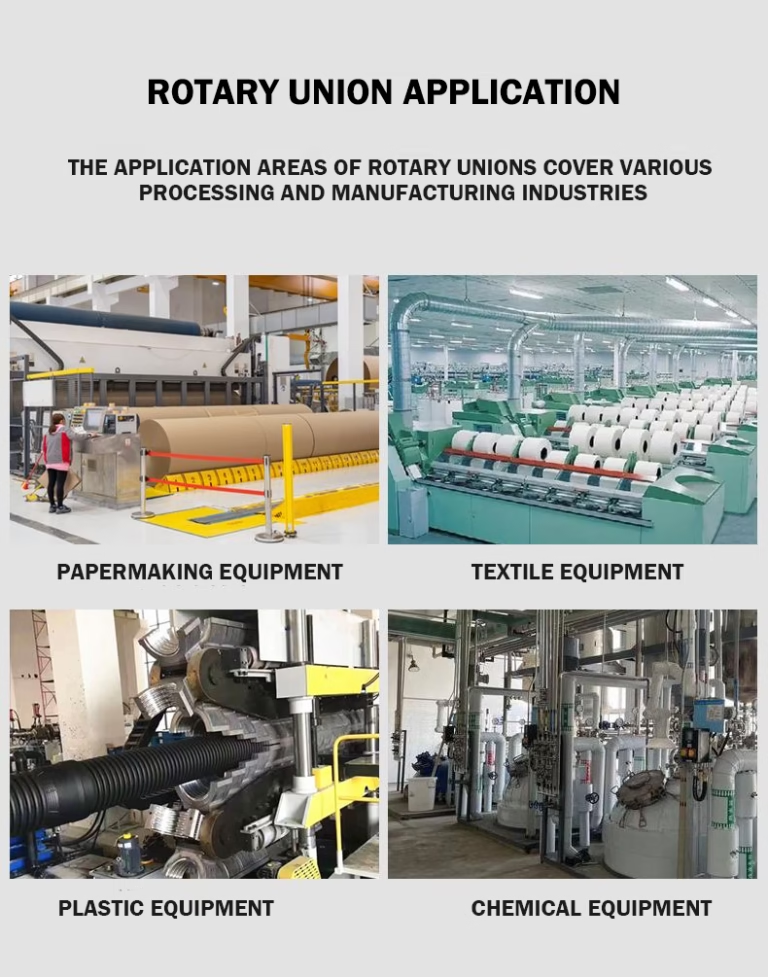

Diverse Applications across Manufacturing Sectors

The applications of rotary union swivel joints span across multiple manufacturing sectors. In the automotive industry, they are crucial for robotic assembly lines, where they enable the movement of fluids for welding guns, paint sprayers, and hydraulic actuators. In the metalworking sector, these joints are used in forging and stamping presses to supply lubricants and coolants to the dies and punches. Additionally, in the packaging industry, rotary union swivel joints play a vital role in the operation of filling and capping machines, ensuring accurate and consistent product dispensing. Each application demands specific performance characteristics from the rotary union swivel joints, such as high-pressure resistance, chemical inertness, or high-speed stability.

Market Analysis: Understanding the Landscape

Current Market Trends

The market for rotary union swivel joints is experiencing several notable trends. One of the prominent trends is the increasing demand for more efficient and energy-saving designs. As manufacturers strive to reduce their operational costs and environmental impact, there is a growing preference for rotary union swivel joints that minimize fluid leakage and friction. For example, the development of advanced sealing technologies, like double-lip seals with self-adjusting capabilities, has led to significant improvements in energy efficiency. Another trend is the rise of customization. With the diversification of manufacturing processes, customers are increasingly seeking rotary union swivel joints that can be tailored to their specific requirements, such as unique connection interfaces or specialized material compositions.

Competitive Analysis

The competitive landscape for rotary union swivel joint manufacturers is highly competitive. Large multinational corporations dominate the market with their extensive product portfolios, global distribution networks, and strong brand recognition. These companies often invest heavily in research and development, enabling them to introduce innovative products regularly. However, smaller, specialized manufacturers also have their niche in the market. They differentiate themselves by offering high-quality, customized solutions and personalized customer service. For instance, some small-scale manufacturers focus on serving the needs of the aerospace or medical device industries, where precision and reliability are of utmost importance. To succeed in this competitive environment, it is essential to clearly define your unique selling proposition (USP) and target the right customer segments.

Customer Needs and Pain Points

Understanding the needs and pain points of your customers is the key to effectively offering rotary unions for sale. Industrial engineers and plant managers are primarily concerned with the performance and reliability of the joints. They need products that can withstand harsh operating conditions, have a long service life, and require minimal maintenance. Procurement managers, on the other hand, focus on cost-effectiveness, delivery times, and supplier relationships. They are constantly looking for suppliers who can offer competitive prices without compromising on quality. Maintenance technicians often face the challenge of replacing faulty rotary union swivel joints quickly and efficiently. They need products that are easy to install and have readily available spare parts. By addressing these needs and pain points in your marketing and product development efforts, you can build strong customer relationships and increase customer loyalty.

Product-Specific Strategies for Sales

Product Differentiation

To stand out in the market, it is crucial to differentiate your rotary union from the competition. This can be achieved through several means. One approach is to focus on product innovation. For example, developing rotary union swivel joints with integrated sensors that can monitor parameters such as temperature, pressure, and vibration in real time. These smart joints can provide valuable data for predictive maintenance, reducing downtime and maintenance costs for customers. Another way to differentiate is by offering superior materials and manufacturing processes. Using high-grade alloys for housing and advanced machining techniques can result in joints with higher strength, better corrosion resistance, and improved precision.

Customization Options

As mentioned earlier, customization is becoming increasingly important in the market. Offering a wide range of customization options can significantly enhance the appeal of your products. This can include customizing the size, shape, and connection types of the rotary union swivel joints to fit specific machinery requirements. You can also offer customization in terms of materials, seals, and lubrication systems. For example, for applications in the food and beverage industry, you can provide rotary union swivel joints made from FDA-approved materials and with hygienic seals to meet strict cleanliness standards. By working closely with customers to understand their unique needs and providing tailored solutions, you can increase customer satisfaction and gain a competitive edge.

Quality Assurance and Certification

In the manufacturing industry, quality is non-negotiable. Implementing a rigorous quality assurance program is essential to ensure that your rotary union swivel joints meet or exceed industry standards. This includes conducting thorough inspections at every stage of the manufacturing process, from raw material sourcing to final product assembly. Certifications such as ISO 9001 for quality management systems and ISO 14001 for environmental management systems can also enhance your credibility in the market. For applications in regulated industries. Such as aerospace and medicine, obtaining specific industry-relevant certifications, like AS9100 for aerospace or ISO 13485 for medical devices, is crucial. Communicating your quality assurance efforts and certifications to customers can build trust and confidence in your products.

Marketing and Promotion Strategies

Industry-Specific Marketing Channels

To effectively promote your rotary union swivel joints, it is important to utilize industry-specific marketing channels. Trade shows and exhibitions are excellent platforms to showcase your products to a targeted audience of industry professionals. Participating in events such as the International Manufacturing Technology Show (IMTS) or the Hannover Messe can provide opportunities to network with potential customers, demonstrate the features and benefits of your products, and stay updated on the latest industry trends. Industry publications, both print and online, are another valuable marketing channel. Advertising in magazines like “Manufacturing Business Technology” or publishing articles and case studies on industry-related websites can help increase brand awareness and position your company as an industry expert.

Content Marketing

Content marketing is a powerful strategy for attracting and engaging customers. Creating high-quality, informative content related to rotary union swivel joints can help build trust and credibility with your target audience. This can include blog posts, whitepapers, videos, and case studies. For example, a blog post titled “The Impact of Rotary Union Swivel Joints on Manufacturing Efficiency” can provide valuable insights into how these components contribute to overall production performance. Whitepapers on topics such as “Advanced Sealing Technologies for Rotary Union Swivel Joints” can showcase your technical expertise and attract customers who are looking for in-depth information. Videos demonstrating the installation, operation, and maintenance of your rotary union swivel joints can be highly engaging and educational for customers.

Sales and Customer Service Strategies

Building Strong Sales Teams

A well-trained and knowledgeable sales team is essential for effectively selling rotary union swivel joints. Sales representatives should have a deep understanding of the technical aspects of the products, as well as the needs and pain points of customers. Provide regular training to your sales team on product features, industry trends, and sales techniques. Encourage them to build strong relationships with customers by providing excellent customer service and personalized solutions. A good salesperson should be able to identify the specific requirements of each customer and recommend the most suitable rotary union swivel joints for their applications.

Customer Service Excellence

Providing exceptional customer service is key to customer satisfaction and retention. Offer prompt and reliable technical support to customers, both before and after the sale. This can include providing product installation guides, troubleshooting assistance, and maintenance advice. Ensure that your customer service team is responsive to customer inquiries and complaints. A satisfied customer is not only likely to make repeat purchases but also to recommend your products to others. Consider implementing a customer relationship management (CRM) system to track customer interactions, manage leads, and improve customer service processes.

After-Sales Support and Maintenance Services

In addition to customer service, offering after-sales support and maintenance services can add significant value to your products. Provide regular maintenance services, such as seal replacements, lubrication checks, and performance inspections, to ensure the long-term reliability of your rotary union swivel joints. Offer spare parts inventory management services to ensure that customers can quickly obtain the parts they need for repairs and replacements. By providing comprehensive after-sales support, you can build long-term relationships with customers and differentiate your company from competitors.

FAQ

Q1: Can I customize rotary union swivel joints for unique applications?

Answer: Absolutely! Reputable manufacturers offer custom-engineered rotary union swivel joints tailored to your specific requirements. Whether you need specialized pressure ratings (up to 15,000 PSI), temperature resistance (-60°C to 450°C), or compatibility with corrosive media (e.g., seawater, chemicals), customization is achievable. Top suppliers provide CAD-driven design consultations and rapid prototyping to ensure seamless integration with your system. Always request compliance with industry standards like ASME B31.3 or API 682 for hazardous environments.

Q2: What industries commonly use rotary union swivel joints?

Answer: Rotary unions are versatile across industries requiring dynamic fluid/gas transfer. Key applications include:

Oil & Gas: Drill pipe rotation, mud motors, and hydraulic swivels.

Robotics: Power and coolant transfer in rotating joints.

Energy: Yaw drives in wind turbines and solar trackers.

Food & Beverage: Rotary fillers and packaging machinery.

Medical: CT scanners and MRI equipment.

Most suppliers offer industry-specific certifications (e.g., ATEX for explosive zones, FDA compliance for food-grade applications) and provide technical guidance on installation and compatibility.

Q3: What maintenance do rotary union swivel joints require?

Answer: Proper maintenance extends the lifespan of your swivel joints. Follow these best practices:

Lubrication: Adhere to manufacturer schedules (e.g., grease every 1,000 hours for mechanical seals).

Inspections: Check monthly for leaks, wear, or corrosion.

Alignment: Ensure rotor/stator concentricity during installation.

Cleaning: Remove debris to prevent seal damage.

Most manufacturers offer preventive maintenance plans, spare parts kits, and 24/7 technical support. Warranties typically range from 1–5 years, depending on the model. For harsh environments, consider smart sensors for real-time monitoring of seal health and temperature.

Conclusion

Effectively offering rotary union swivel joints for sale in the manufacturing industry requires a comprehensive approach that combines in-depth market understanding, product-specific strategies, targeted marketing and promotion, and excellent sales and customer service. By leveraging your industry expertise, staying updated on the latest trends, and focusing on meeting the needs of your customers, you can build a successful business and establish a strong reputation in the market. Remember, the key to success lies in continuous innovation, quality improvement, and customer satisfaction. With the right strategies and a commitment to excellence, you can achieve your sales goals and contribute to the growth and success of the manufacturing industry.